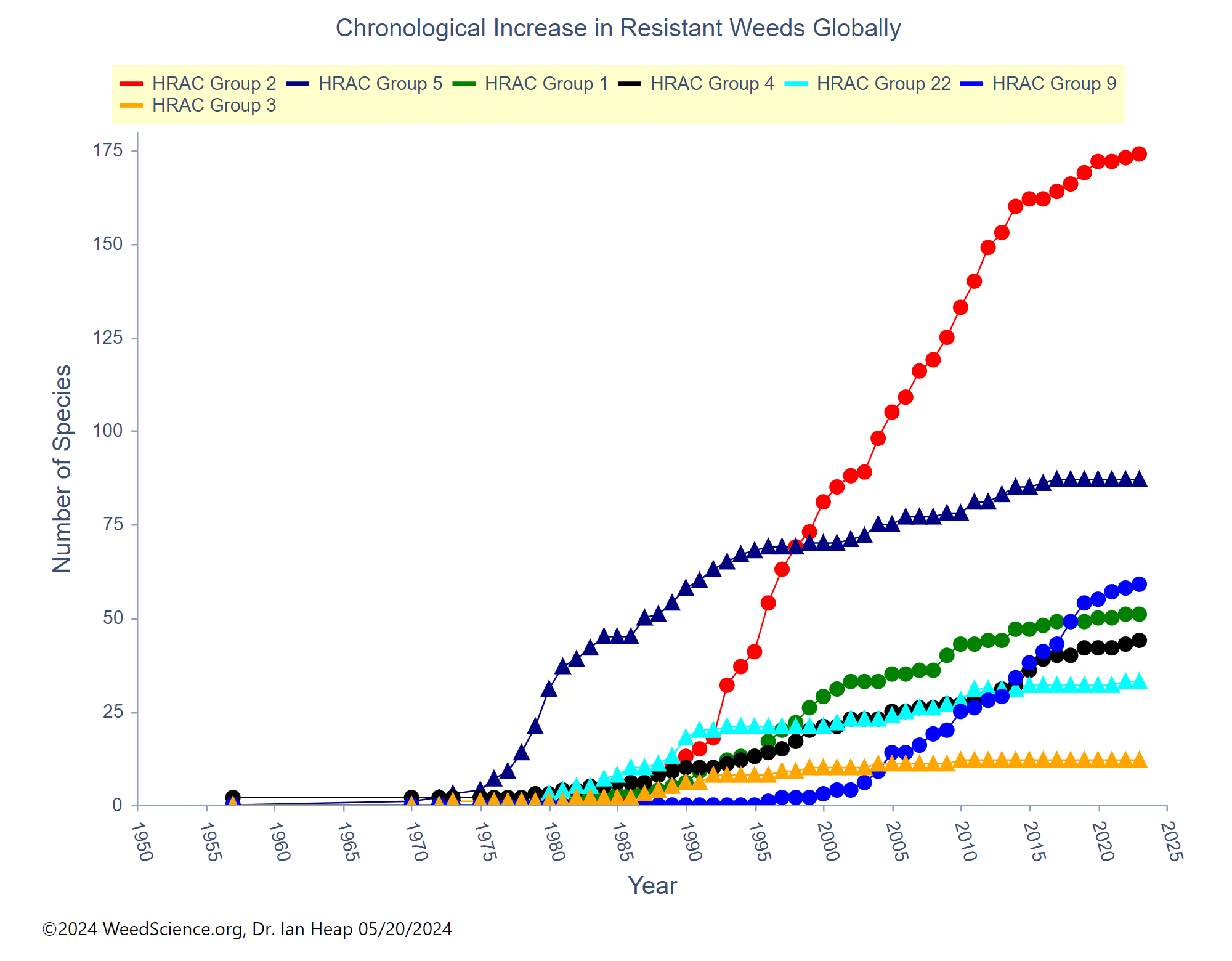

Killing weed seeds is dirty work, but with herbicide-resistant weeds on the rise, someone has to do it!

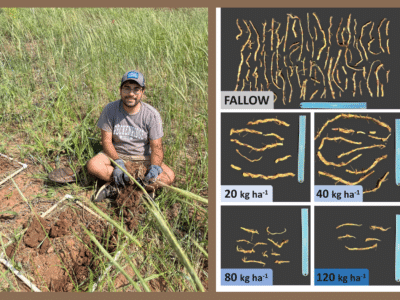

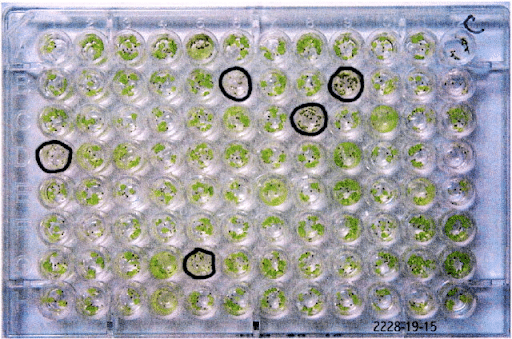

That’s why Virginia Tech Ph.D. Student Eli Russell and his teammates have been donning masks and braving the dust to see if weed seeds that enter a combine during harvest get caught and destroyed by the Redekop Seed Control Unit (SCU), a type of seed impact mill.

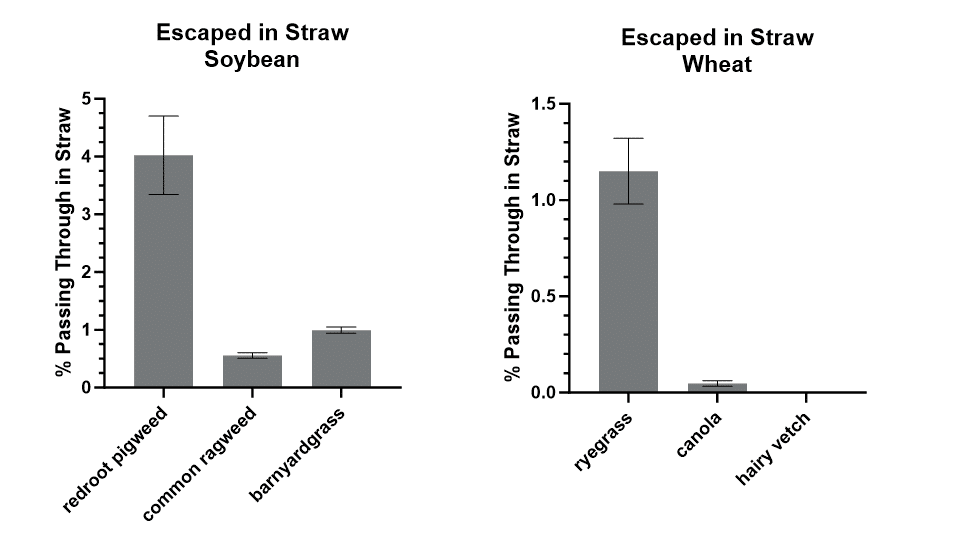

The research is ongoing, but the early results are promising. Fewer than 5% of weed seeds that enter the combine are returning to the field through the straw chopper and spreader, Russell reports. That means that the vast majority of weed seeds that enter the combine are delivered to the Redekop SCU. Some seeds may be going into the grain tank, which isn’t ideal and was not examined in the research, but would still result in removal from the field, Russell adds.

Research Shows Promise

The Virginia Tech team has been testing the Redekop SCU during wheat and soybean harvests on Virginia’s Eastern Shore since 2020. It’s proving quite deadly to weed seeds.

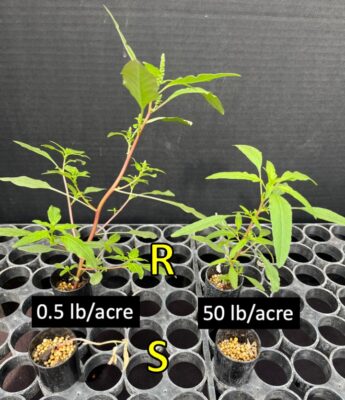

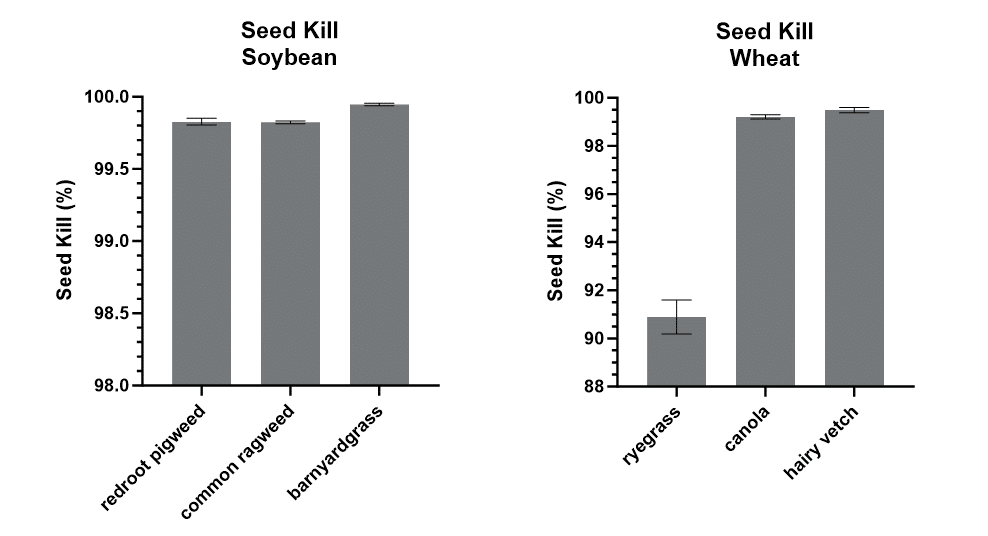

All of the weeds tested in soybeans and most tested in wheat were experiencing kill rates of 98% from the Redekop unit. Ryegrass proved the toughest weed to kill during wheat harvest, but the impact mill was still destroying over 90% of its seeds.

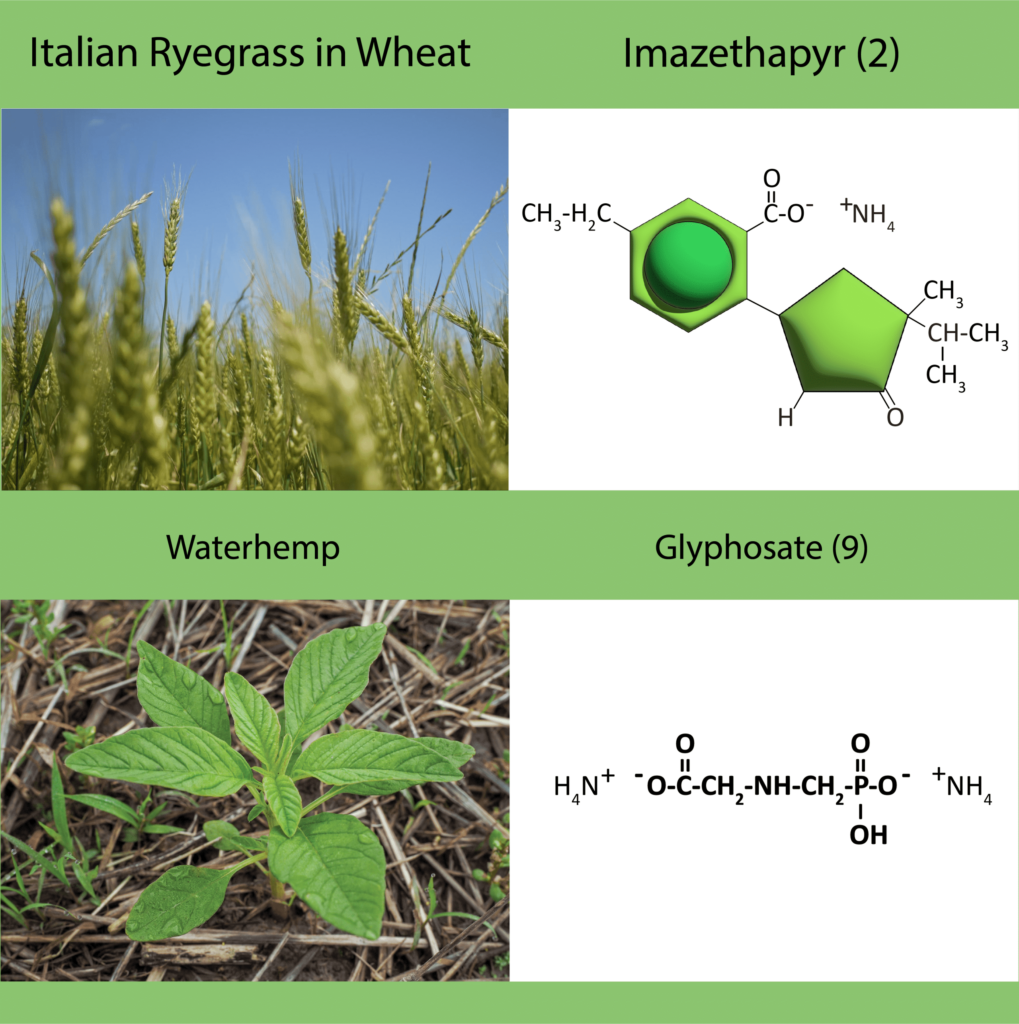

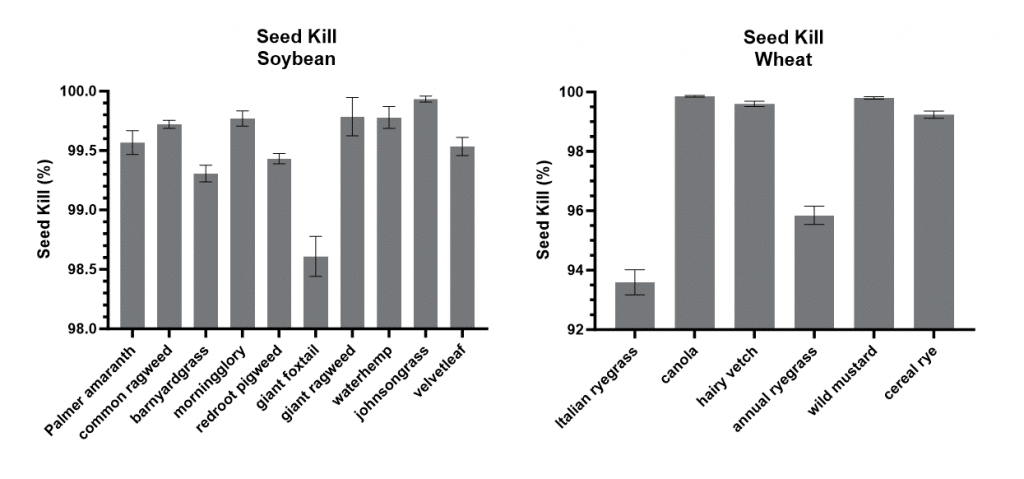

To avoid introducing damaging new weeds like Palmer amaranth and waterhemp into production fields, the researchers also used a stationary test stand of the Redekop SCU.

As that test stand research nears completion, the researchers are seeing similarly high weed seed kill rates, ranging from 93% to 99% in wheat chaff and over 98.5% in soybean chaff.

The Virginia Tech team also used the stationary test stand to examine a broader range of harvest conditions, such as moisture levels, which can influence seed kill.

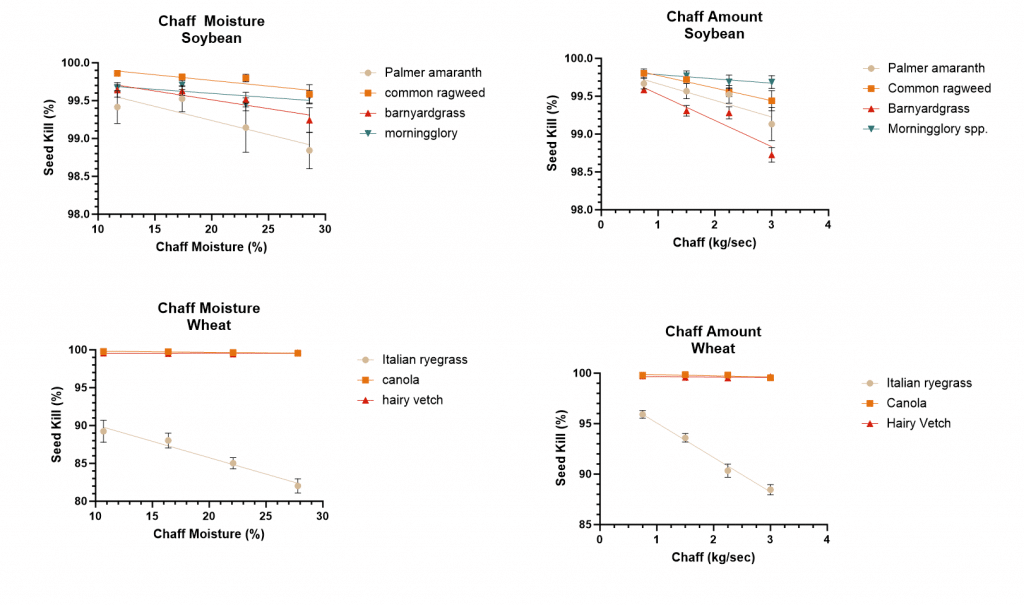

The level of moisture in harvest residues, such as chaff, can be quite different from grain moisture. To determine the effects this might have on the seed impact mill, Russell and his teammates fed weed-seed-infested wheat and soybean chaff into the units, while ramping up moisture levels. Ultimately, they found only a minimal impact on weed seed kill rates for most weed seeds from rising chaff moisture. One exception was Italian ryegrass; the kill rate dropped from nearly 90% to 82% as wheat chaff moisture rose above 25%.

Chaff flow, which will vary in low or high-yielding fields, can also influence seed kill rates. A good combine operator will adjust speed to maximize the sieve capacity, but adjustments are not instantaneous. So, the researchers tested the SCU at half of harvest capacity up to twice the normal throughput. As chaff flow increased, the weed seed kill rate for ryegrass did drop slightly (by 8%), but kill rates remained over 98% for all other weeds tested.

Weed Seeds Don’t Always Cooperate

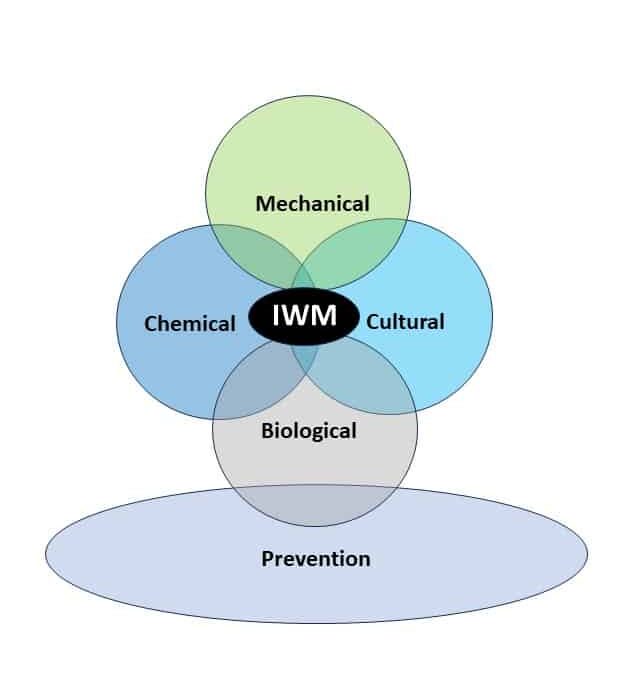

Since most of the weed seeds entering the combine travel through the Redekop and are destroyed there, the Virginia Tech researchers see a high potential benefit from this technology for growers looking to manage weeds at harvest.

But — they caution — weed seeds don’t always cooperate.

Several grassy weed species have been shown to shatter more than 50% of their seeds to the ground before combines even start rolling at harvest time (San Martin et al. 2021; Schwartz-Lazaro et al. 2021).

Broadleaves tend to be more cooperative – previous research shows that many of the most troublesome broadleaf weeds retain most of their weed seed until harvest (Schwartz-Lazaro et al. 2021). But newer research has found that some species, like waterhemp, will have roughly 30% of their seeds knocked onto the ground by the reel and cutter bar, and never make it into the combine (Winans et al. 2023).

And corn harvest remains a less certain success for seed impact mills. Initial reports from recent research show corn headers capture significantly fewer weed seeds than grain or soybean headers (Schreier et al. 2023).

Combine Performance Matters

When harvesting conditions produce high chaff moisture, such as an abundance of green plant material might cause, two potential issues arise. The horsepower draw of the mill increases, and combine or mill blockages can occur. (Both issues are the subjects of ongoing research.)

Moreover, due to the extra horsepower requirements for a combine to operate a seed impact mill, some farmers have noticed a decrease in harvest speed. The extra horsepower also results in more fuel use during harvest. While Class 7 combines can handle a seed impact mill, a Class 8 or larger is ideal for running a seed impact mill, the Virginia Tech researchers have observed.

Does the SCU result in fewer weeds in subsequent seasons? This is the subject of a large GROW research project across several states, many of which had their first harvest in 2022. The study also includes several locations with an iHSD, another brand of seed impact mill, as well as in crop rotations that include corn.

Stay tuned to the GROW News Page for more results, and watch a video of the Virginia Tech team’s research in action here.

This work is funded by the USDA NRCS On-Farm CIG program, the USDA ARS Areawide program, and the USDA NIFA. Redekop Manufacturing provided the equipment for testing.

Text and photos by Dr. Michael Flessner, Virginia Tech Extension Weed Specialist, and Eli Russell, Virginia Tech Ph.D. student

Citations

Russell EC, Flessner ML. Evaluating Weed Seed Kill Efficacy and Horsepower Draw of Two Impact Mills for Use in Soybean Production. Weed Science. Published online 2025:1-19. doi:10.1017/wsc.2025.14

Russell EC, Flessner ML. Evaluating Two Impact Mills Seed Kill Efficacy and Horsepower Draw for Use in U.S. Wheat Production. Weed Science. Published online 2025:1-18. doi:10.1017/wsc.2025.15

San Martín, C., Thorne, M., Gourlie, J., Lyon, D., & Barroso, J. (2021). Seed retention of grass weeds at wheat harvest in the Pacific Northwest. Weed Science, 69(2), 238-246. doi:10.1017/wsc.2020.91

Schreier, H. E., Vaughn, J. E., Bradley, K. W., Young, B. G., Norsworthy, J. K., Jha, P., Legleiter, T., & Johnson, B. (2023). Weed Seed Fate at Corn Harvest. Proceedings of the Weed Science Society of America Annual Meeting Vol 63 (pp. 60).

Schwartz-Lazaro, L., Shergill, L., Evans, J., Bagavathiannan, M., Beam, S., Bish, M., . . . Mirsky, S. (2021). Seed-shattering phenology at soybean harvest of economically important weeds in multiple regions of the United States. Part 1: Broadleaf species. Weed Science, 69(1), 95-103. doi:10.1017/wsc.2020.80

Schwartz-Lazaro, L., Shergill, L., Evans, J., Bagavathiannan, M., Beam, S., Bish, M., . . . Mirsky, S. (2021). Seed-shattering phenology at soybean harvest of economically important weeds in multiple regions of the United States. Part 2: Grass species. Weed Science, 69(1), 104-110. doi:10.1017/wsc.2020.79

Winans, T., Massey, R., Schreier, H., Bish, M., & Bradley, K. (2023). Harvest weed seed control in soybean with an impact mill. Weed Technology, 37(2), 113-122. doi:10.1017/wet.2023.20