Harvest Weed Seed Control

A powerful non-herbicide weed control tactic to tackle herbicide resistance

At harvest time, weeds that have escaped season long management often have mature seed still attached to the parent plants. These weed seeds can enter the combine along with the cash crop, exit the back of the combine as chaff (small plant pieces and weed seeds), and be spread across the field, as well as from one field to another. It seems a waste to spend all year spraying weeds with expensive herbicides only to reward the survivors at harvest by spreading their weed seeds out for next year.

An excellent way to stop weeds in their tracks is to collect these weed seeds at harvest and either destroy them or deposit them in a known location where they can be monitored and controlled later. Soybean, wheat, and other crops harvested with a grain header are ideal choices for harvest weed seed control (HWSC). Other crops such as cotton and corn need further equipment development to make HWSC a viable option.

If you are considering adding harvest weed seed control (HWSC) to your weed control program there are excellent resources on the WeedSmart website to help guide you through the initial decisions and the implementation of this important weed control tool.

3 steps to get it working for you

1. Decide which system fits your farm best.

2. Get maximum weed seed into the header.

3. Know how to manage the collected weed seed.

What is Harvest Weed Seed Control?

Choose The Best System For You

Which system is best?

HWSC is being rapidly adopted in Australia and other countries around the world. There are six systems currently being used on Australian farms and they have been initially developed by farmers.

Research has demonstrated that all are very effective weed seedbank management tactics for a range of weed species, achieving over 80 percent control and for some nearly 100 percent.

See HWSC in Action

Over 80% weed control for species that retain seed at harvest

Crop residue management

There are six systems currently used to collect and manage weed seed at harvest. They can be grouped according to the way crop residue is managed: chaff only or chaff + straw.

CHAFF ONLY

Chaff carts are a tow-behind unit on the combine that collects the weed seed-laden chaff, which can then be placed into piles that are later either grazed by livestock, burnt, or both and sown through the following season. Chaff carts are often chosen for use on mixed cropping and livestock farms in Australia as the chaff is an excellent livestock feed; however, spreading manure back onto fields can allow for further seed spread.

Chaff lining funnels the chaff and weed seeds into narrow rows behind the combine, where the residue is left to overwinter. The weed seeds are exposed to natural elements that can lead to weed seed decay and predation. Typically a follow-up herbicide application is required. – Chaff lining is usually considered a good entry-level HWSC option.

Chaff decks (chaff tramlining) are similar to chaff lining, but place the chaff in one or both of the combine’s wheel tracks. The added compaction from the wheels can be beneficial in controlled traffic systems.

Impact mills run the chaff through a mill that pulverizes (destroys) the weed seed, which is then spread across the fields. This technology is usually considered the ultimate in HWSC.

CHAFF + STRAW

Bale direct collects all the crop residue directly from the combine and compacts it into large bales suitable for sale.

Narrow windrow burning collects all of the crop chaff and straw residue, and funnels it into narrow rows in the field. These rows are burnt to destroy the weed seed. This method is effective but removes all of the crop residue from the field.

Learn More About Each System in This Research Report

Calculate the cost

While each HWSC tactic is similarly effective in collecting weed seeds , they vary considerably in capital and ownership cost, nutrient removal costs, operational costs, and labor costs. Some HWSC tactics involve the purchase of substantial machinery – such as an impact mill, chaff cart, or chaff deck – but the operational and labor costs might be lower than methods such as narrow windrow burning, which involves low set-up costs but higher nutrient losses and labor costs associated with burning. Chaff lining is often chosen as the best entry-level tactic that requires minimal set-up cost, no additional labor and minimal nutrient loss or redistribution. To calculate the cost of each method for your farm you can use a calculator developed by WeedSmart’s Peter Newman. Download the calculator or learn more here.

Beware of the Real Cost of Nutrient Removal

Low-cost setup

The HWSC tools all involve some modification to the combine. The simplest modification is for chaff lining and narrow windrow burning, where a chute is attached to the rear of the combine to direct the residue into a band on the ground, running the same direction as the combine has travelled.

These chutes are often constructed and fitted on-farm. All the other systems are commercial modifications that are fitted to the combine – chaff decks and impact mills – or trail behind the harvester – chaff carts and bale direct.

Click the image to download a chaff lining guide

Mechanized systems

Once convinced of the benefits of HWSC, many farmers invest in a mechanized system. The chaff decks, impact mills, chaff carts, and bale direct systems are usually designed to fit specific combine makes and models, and fitted by the various manufacturers. There are currently three impact mill manufacturers selling into the North American market.

Click the logos to learn more about each of the Impact Mill options

Get the Weed Seed in the Header

HWSC only works on weed seed that enters the header

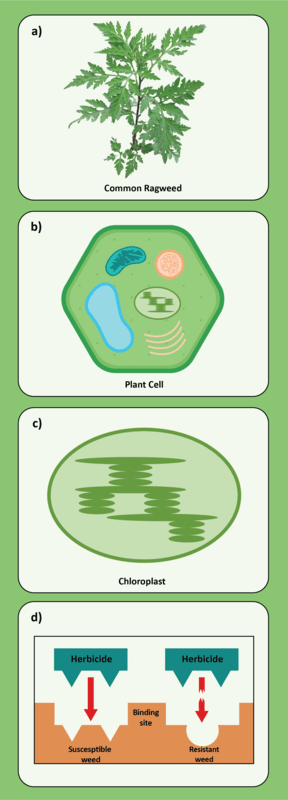

Getting the weed seed into the header relies on the seed being held on the seed head at the time of harvest. The seed head must also be at harvestable height.

Consider the weed spectrum present in a field and the likelihood of seed capture. Even if some seed has been shed, chances are there will be other seed heads that have not yet shattered. Every little bit helps: every weed seed collected and controlled at harvest is a weed seed that will not enter the seed bank and potentially become a weed that needs to be controlled in the future.

The chaff-only systems –chaff lining, chaff decks, impact mills, and chaff carts – require the combine to be set up to separate chaff and straw, and to keep the weed seed in the chaff stream.

This may require modifications to the combine rotor and sieves and the installation of a baffle to keep the weed seed in the chaff stream.

If you choose one of the chaff + straw systems –narrow windrow burning or bale direct – all the straw and chaff ends up in the same place, so no other modification to the combine is needed.

1. Get weed seeds into the combine

2. Get weed seeds out of the rotor – concaves/rotor speed

3. Keep weed seeds in the chaff stream – wind/baffles

4. Put weed seeds into one of the six HWSC tools

Learn About Setting Up Your Combine to Maximize Weed Seed Capture

Educate your machinery operators

To maximize the value of HWSC it is important to operate the machine within the optimal parameters to achieve separation of grain and weed seed.

The cutting bar also needs to be kept low (around 6 inches above ground level), which often requires slower ground speeds.

When using a stripper front at harvest it is even more important to ensure that the weed seed heads are held high in the canopy so they will enter the combine. High biomass crops and strong crop competition are the best ways to achieve this.

To achieve consistent weed control it is essential that all personnel involved in the harvest operation understand the requirements for successful weed seed capture and the specific requirements of the HWSC tactic used on your farm.

Manage the Weed Seed

Finishing the job

If you choose an impact mill as your HWSC tool then the tactic is completed in one pass at harvest, with nothing extra to do. All of the residue is spread in the field and the weed seeds are rendered nonviable. All of the other HWSC tools involve some action after harvest to remove or destroy the weed seed collected at harvest.

Chaff decks deposit the weed seed-laden chaff in one or both combine tramlines or wheel tracks. Some growers find that the chaff rots and the weed seeds die, but in other environments growers find that it is necessary to control weeds that germinate in the tramlines using herbicide or non-herbicide tactics applied just to the tramlines.

Chaff lines are usually left unmanaged with the expectation that the following crop will provide adequate competition to the weeds to minimize weed growth and seed production.

Chaff carts can be emptied as they fill in the field or emptied at a central point. Many growers use the collected chaff piles as a high nutrient value livestock feed. After grazing, some farmers burn the piles while others leave them unburned and sow through them the following season. Chaff piles can be baled and transferred to a feedlot. Alternatively, the chaff piles can be burned in order to seed the following season.

Narrow windrow burning uses fire to destroy the weed seed following harvest. There are significant labor costs and safety risks to consider along with the loss of nutrients and ground cover.

The bale direct system results in large bales of crop residue that can be sold to suitable markets. Distance to market is usually an important factor in the success of this system for HWSC.

Find More Insights

Special Thanks

Contributors

- Victoria Ackroyd

- Michael Flessner

- Lauren Lazaro

- Steven Mirsky

- Claudio Rubione

- Mark VanGessel

Resources:

- Haring, SC, ML Flessner. 2018. Improving soil seed bank management. Pest Management Science 74:2412-2418. https://doi.org/10.1002/ps.5068

- Korres, NE, JK Norsworthy, BG Young, DB Reynolds, WG Johnson, SP Conley, RJ Smeda, TC Mueller, DJ Spaunhorst, KL Gage, M Loux, GR Kruger, MV Bagavathiannan..2018. Seedbank persistence of Palmer amaranth (Amaranthus palmeri) and waterhemp (Amaranthus tuberculatus) across diverse geographical regions in the United States. Weed Science 66:446–456. https://doi.org/10.1017/wsc.2018.27

- Norsworthy, JK, NE Korres, MV Bagavathiannan. 2018. Weed Seedbank management: Revisiting how herbicides are evaluated. Weed Science 66:415–417. https://doi.org/10.1017/wsc.2018.11

- Schwartz-Lazaro, LM, JT Copes. 2019. A Review of the Soil Seedbank from a Weed Scientists Perspective. Agronomy 9:369. https://doi.org/10.3390/agronomy9070369

- Shergil, LS, LM Schwartz-Lazaro, R Leon, VJ Ackroyd, ML Flessner, M Bagavathiannan, W Everman, JK Norsworthy, MJ VanGessel, SB Mirsky. 2020. Current outlook and future research needs for harvest weed seed control in North American cropping systems. Pest Management Science https://doi.org/10.1002/ps.5986

- Walsh, M, P Newman, S Powles. 2013. Targeting weed seeds in-crop: A new weed control paradigm for global agriculture. Weed Technology 27:431–436. https://doi.org/10.1614/WT-D-12-00181.1