Do you have a passion for finding alternative solutions to manage weeds? Do you like to stay up to date on the latest weed management technology? Well, this study is for you! Our team at Cornell has been studying several weed management strategies – shading, mowing, and zapping weeds – to compare how well they work and determine how they might work together as part of an integrated weed management program.

My name is Annika Rowland and I am a graduate student researcher at Cornell University working with Dr. Matthew Ryan. For the past two years, I have been working with three weed management tactics in soybean production: a high soybean seeding rate, inter-row mowing, and weed electrocution.

Each tactic targets weeds differently. The high seeding rate suppresses weeds within the row early in the season, the inter-row mower controls weeds between the rows mid-season, and the Weed Zapper controls weeds above the soybean canopy later in the season. All tools were tested individually and in all possible combinations.

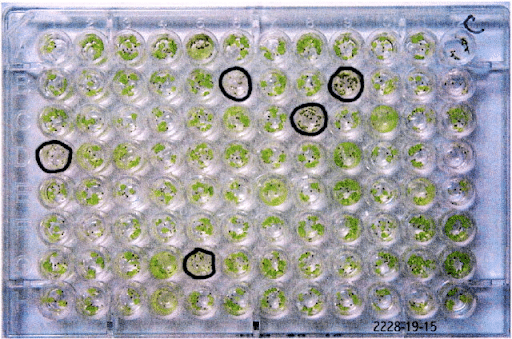

The experimental fields also contained a range of cereal rye cover crop biomass, which was roller-crimped before soybean planting. The cover crop mulch created a baseline barrier for weed germination and has been shown to preserve soil moisture, limit soil erosion, and reduce labor and fuel costs. Two of the experimental fields did not have cereal rye mulch and did not receive additional cultivation during the season. These fields represented a worst-case scenario, where a farmer encountered no or very low mulch levels.

How Did the Different Tactics Play Together?

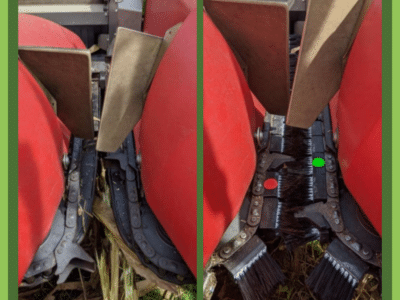

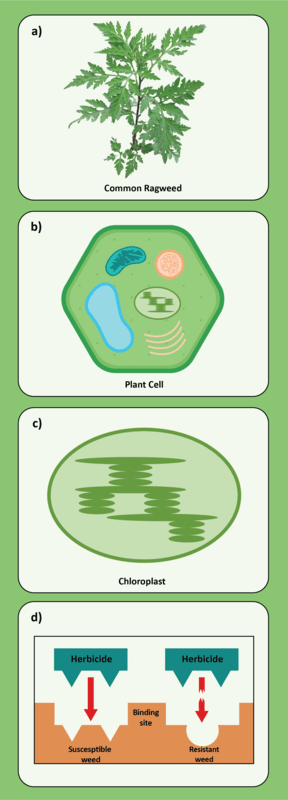

In my experiment, I found that using the inter-row mower alone (IRM-X4, R-Tech Industries Ltd.) reduced weed biomass by 60% compared to the no-weed-management control treatment. In both years of the experiment, inter-row mowing occurred twice when soybeans were at the V4 and V5 growth stage. Weeds were between 6 and 12 inches tall at mowing and consisted mainly of common ragweed, common lambsquarters, and foxtail species.

Adding the high soybean seeding rate and/or weed electrocution to inter-row mowing did not provide additional weed control. Inter-row mowing alone may have been successful because the tool targeted annual broadleaf weeds, which dominated the experimental weed community.

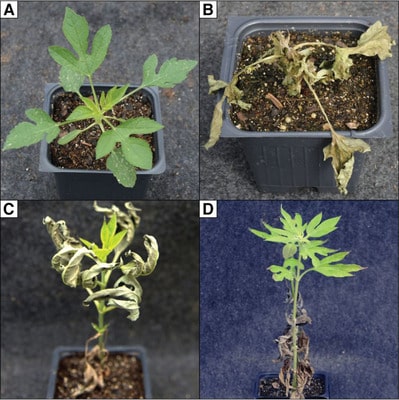

When used alone, the Weed Zapper (6R30 Weed Zapper Annihilator, Old School Manufacturing LLC) did not reduce weed biomass compared to the untreated control. Faster-growing species that may have been controlled by the Weed Zapper, like giant ragweed, horseweed, and waterhemp, were not as present in my experimental fields. These faster growing species were, however, successfully controlled in the University of Missouri’s recent weed electrocution research.

The high seeding rate – 275,000 pure live seeds/acre – also did not reduce weed biomass. Previous research in the Sustainable Cropping Systems Lab here at Cornell has demonstrated that weed suppression increases with soybean seeding rate, as higher seeding rates lead to increased shading from the soybean crop. However, because the baseline seeding rate (175,000 seeds/acre) was already high, there was a limited opportunity for the high seeding rate to increase shading.

How the Different Tactics Affected Soybean Yields

My data indicate that combining a high soybean seeding rate and inter-row mowing led to soybean yields of approximately 37 bu/a, which was 28% higher than the control treatment that did not receive any weed management (29 bu/a). This promising result suggests a multi-tactic approach to weed management can positively impact yield.

The combination of all three tactics did not increase yields compared to the treatment that just combined the high seeding rate and the inter-row mower. Research on the Weed Zapper has indicated the machine generally targets weeds in later growth stages when they have already competed with the crop. The Weed Zapper can serve additional purposes; previous work from the University of Missouri has demonstrated that the machine has the potential to reduce seed additions to the soil weed seedbank.

Adding the Weed Zapper to a weed management toolkit should be carefully considered by farmers, however, as the machine can cost up to $88,500, depending on generator wattage, tractor model, and length of boom. The unit purchased for this experiment was $69,000 and is one of the smallest models, with a 110,000+ watt generator and a 15-foot boom. The inter-row mower used in this experiment was purchased for $30,000, had five mower row units on 30-inch spacing, and was attached to a John Deere 5100R tractor with a category II 3-point hitch. Around the time of this publication, organic soybeans are sold for approximately $24/bu, while conventional soybeans are sold for $14 to $15/bu. Taking this in sum, a farmer must decide if the weed management tactics will increase yields enough to outweigh management costs.

Future of Inter-Row Mower and Weed Zapper Research

The inter-row mower and the Weed Zapper are promising tools for future research. Both machines reduce weed populations, which then lowers the soil weed seedbank because weeds are not producing seeds. The inter-row mower also has the potential to reduce weed-crop competition and weeds between rows, which could increase the ease of harvest. Removing weeds prior to harvest can also increase soybean quality, as weed seeds would be less likely to contaminate grain or stain soybeans during harvest and storage.

The electricity from the Weed Zapper has been shown to reduce weed seed viability, prohibiting weeds from germinating the following year. In addition, researchers at the University of Missouri and Cornell University are already looking into the efficacy of the Weed Zapper in different soil moisture conditions and how the electricity affects soil microbial communities.

Our results show that perennial weeds and grasses were not controlled as effectively with the inter-row mower and the Weed Zapper. The inter-row mower may select for perennial and grass species over time, especially those which grow along the soil surface rather than upright. The Weed Zapper may select for grass-like species and perennials which do not grow tall enough to be contacted by the electricity.

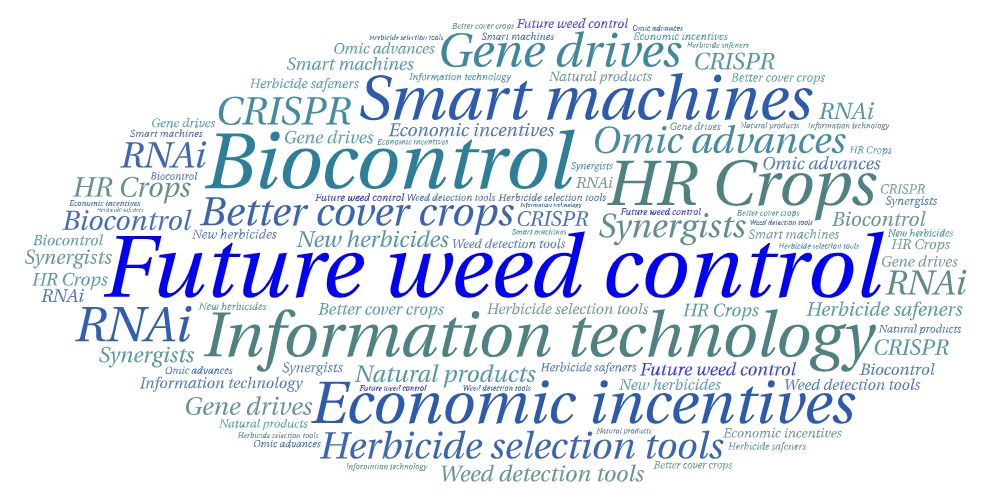

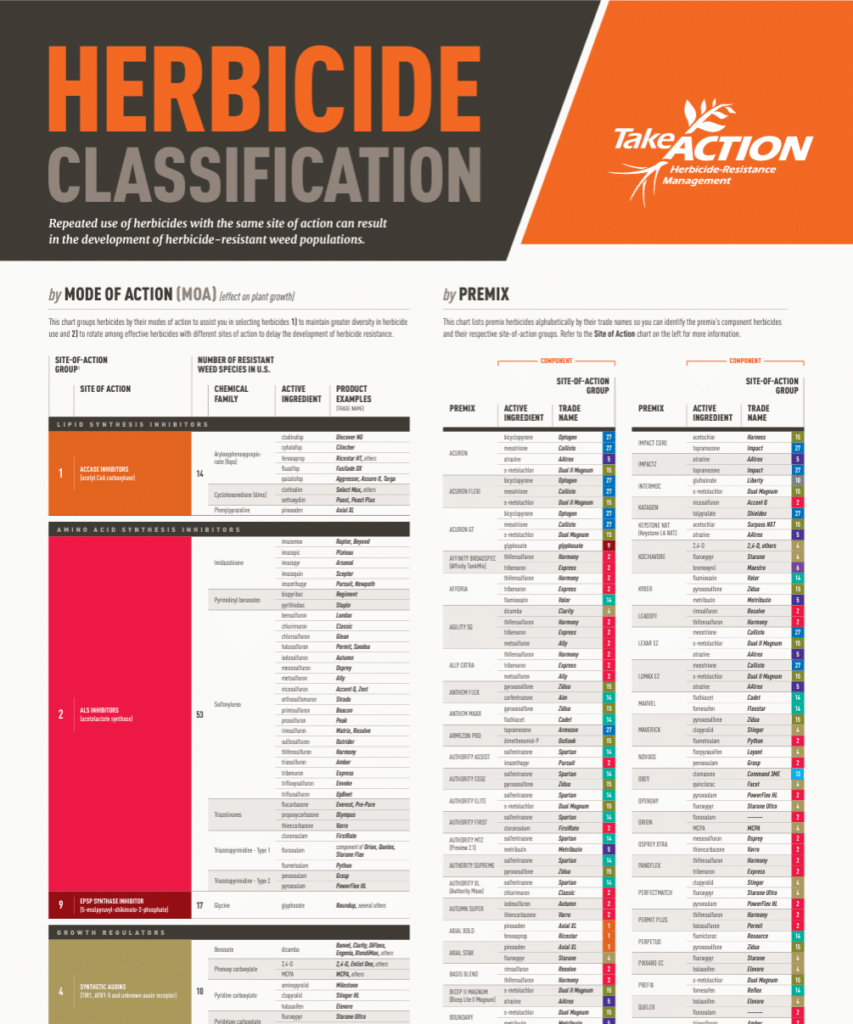

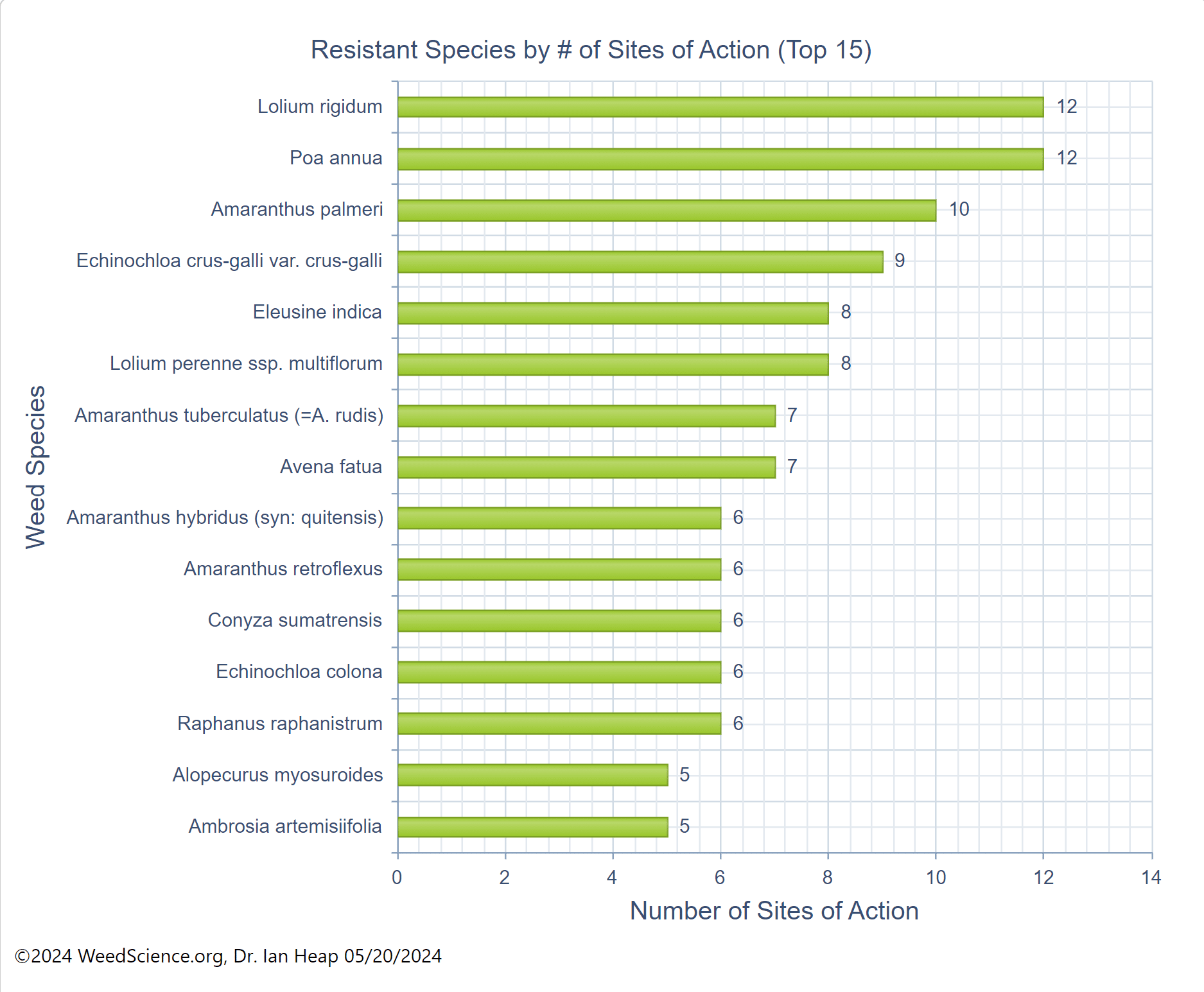

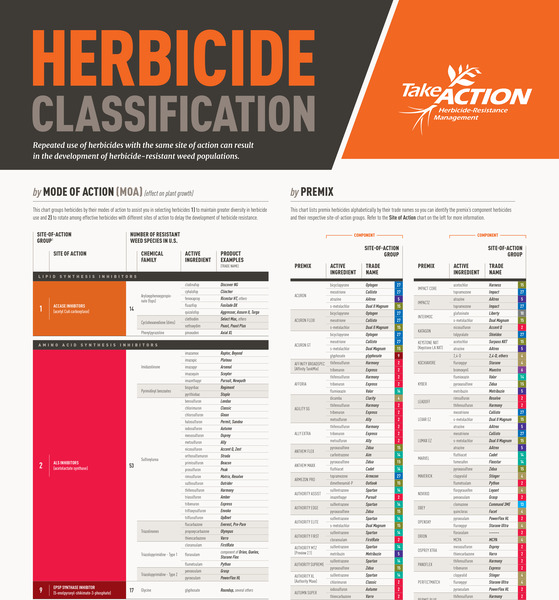

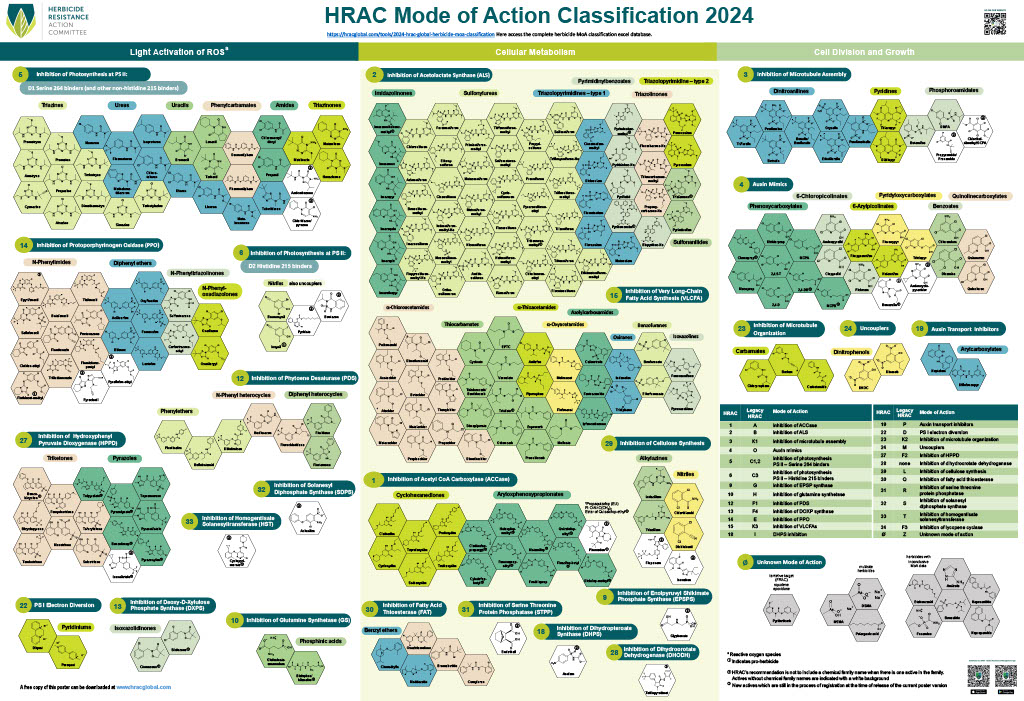

Overall, results suggest that inter-row mowing and weed electrocution have the potential to work as part of a multi-tactic weed management strategy to reduce weed populations and increase soybean yields. Although this research was conducted within the context of organic crop production, these tools could also be used in conventional production and assist with the control of herbicide-resistant weeds, which currently increase national weed management costs by millions of dollars every year. There are many opportunities to integrate the tools into future research, whether that be in combination with harvest weed seed control (HWSC) tools, banded herbicides, or other ecological weed management strategies.

Text and photos by Annika Rowland, Cornell University