Cover Crop Termination

Cover Crop Termination and Weed Management

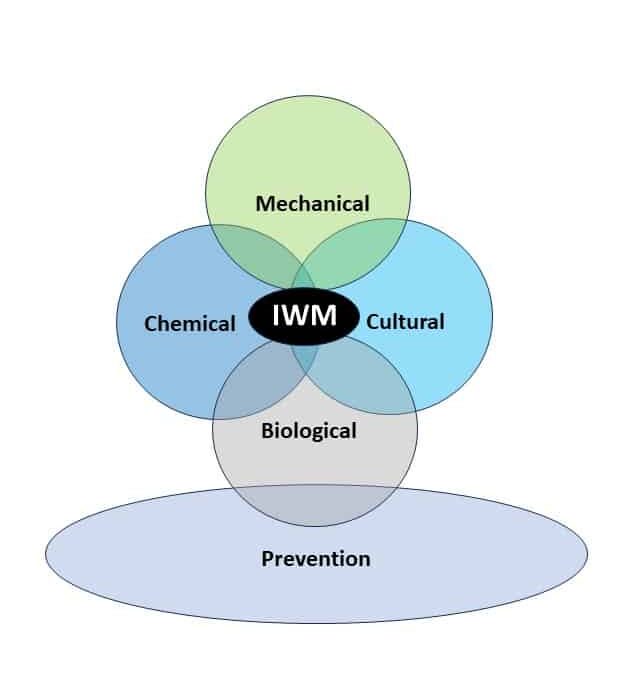

Growers have multiple cover crop termination options to choose from, which can have varying effects on weed suppression and management.

It is important to keep cover crop termination timing and methods in mind when choosing a cover crop. For example, farmers who are just beginning to experiment with cover crops or who have limited time and labor resources may consider growing cover crops that do not survive the winter (known as winterkill). Effective cover crop termination relies on many variables such as termination method, cover crop growth stage, and environmental conditions. The objective of planting the cover crop is also important. For instance, if you are using the cover crop to prevent/minimize erosion, then targeting termination in the early spring is appropriate. On the other hand, if you are aiming to maximize weed suppression with the cover crop, then terminating later in the spring after the cover crop has produced significant amounts of biomass later is the more appropriate timing.

Cover crop termination options can be broadly classified as winter-kill, mechanical, or chemical methods. You can find more details on the different termination strategies, as well as information about the practice of planting green, on this page.

Looking for a quick overview? This video provides some important advice on selection and termination of cover crops when weed suppression is a key goal.

Termination Options

1. Winter-kill Termination

- Some common cover crops, including fall-planted oats and forage radishes, usually winter-kill (i.e. fail to survive the winter).

- Such cover crops typically require little to no time commitment for termination.

- These species can be quite effective in managing winter annual weeds, but have little to no impact on weeds germinating in the late spring or summer.

- If the cover crop survives the winter due to mild weather, it may be necessary to terminate the cover crop using another means before planting the cash crop.

- Winter-killed cover crops do not provide as many ecosystem services, such as weed control in the spring, as cover crops that overwinter and then continue growing in the spring.

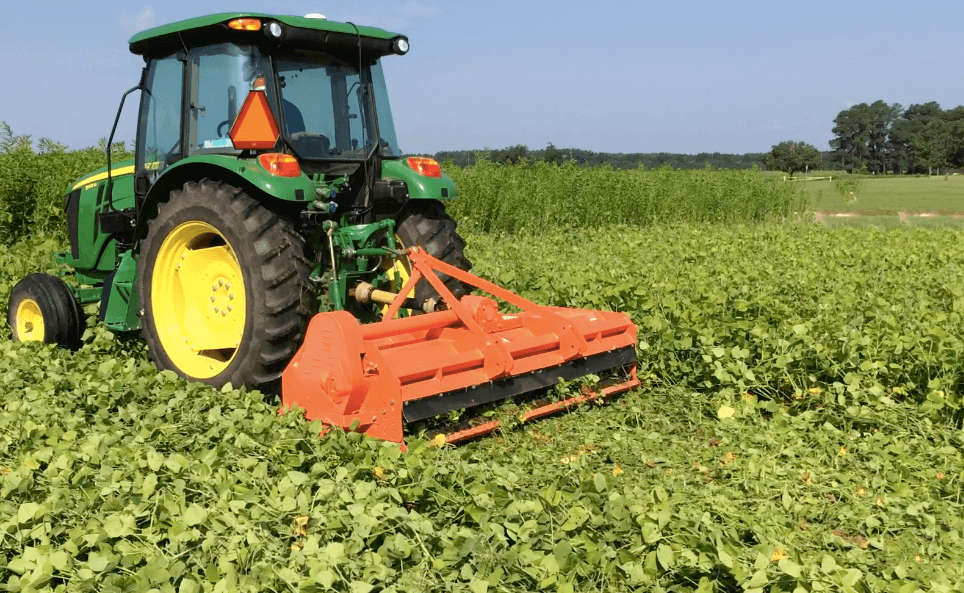

2. Mechanical Termination: Roller Crimpers, Tillage and Mowing

Roller-Crimper

What is a roller-crimper?

A roller-crimper is an implement used to terminate some cover crops. This implement consists of a round drum with angled fins, often weighed down with water, that knock down a cover crop and damage or break the vascular system to kill the plants. Newer versions of the roller-crimper consist of two mechanisms: a smooth drum with a spring-loaded crimping device right behind. This design, though it has more components, provides the crimper with more force with which to effectively kill the cover crop. Learn more about the advantages and limitations of roller-crimping here.

- Roller-crimping is an option for many cover crop species.

- Out of all the mechanical methods listed, roller-crimping is the most successful for weed management as it turns the cover crop into a residue “mulch”.

- Timing is crucial for successful termination with a roller-crimper.

- Roller crimping is less effective when cover crops are experiencing moisture stress.

- Grass cover crops should be roller-crimped after they start flowering (anthesis).

- Legumes such as hairy vetch should be roller-crimped after they start to produce pods.

- When terminating cover crop mixtures, it is very difficult to achieve excellent control with just one pass since different species mature at different times. Use the roller-crimp at the optimum timing for the latest-maturing species in the mixture unless multiple passes are possible.

- Depending on field conditions, the need to roller-crimp a cover crop at the correct stage for best control may delay cash crop planting.

- Many farmers are using roller-crimpers along with herbicides. In this situation, the main function of the roller crimper is to flatten the cover crop.

Tillage

Mowing

3. Chemical Termination

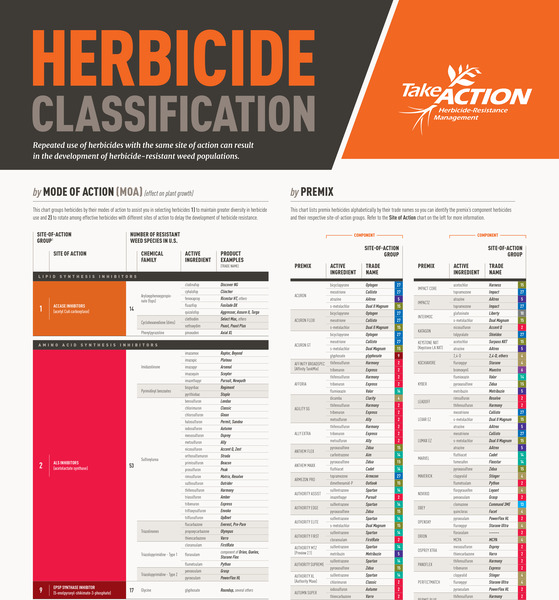

Herbicides are a valuable tool in cover crop termination. Keep the following in mind:

- Herbicides will not kill cover crop seeds. Cover crops that were terminated with herbicides after they had flowered are likely to produce viable seeds.

- Herbicides have more flexible timing windows than mechanical termination methods. They can also be partnered with another termination method, such as roll-crimping, to ensure total termination. Learn more about how to pair herbicides with a roller crimper in this GROW factsheet.

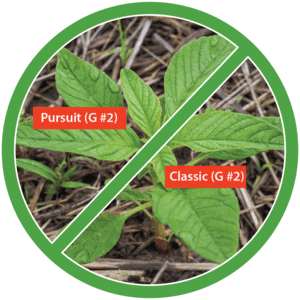

- Herbicides may have rotational restrictions, so product choice depends on both cash and cover crop species in use.

- Most cover crops can be terminated with herbicides.

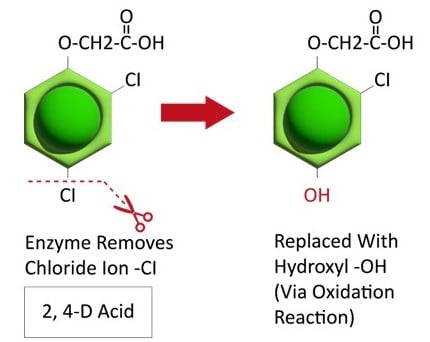

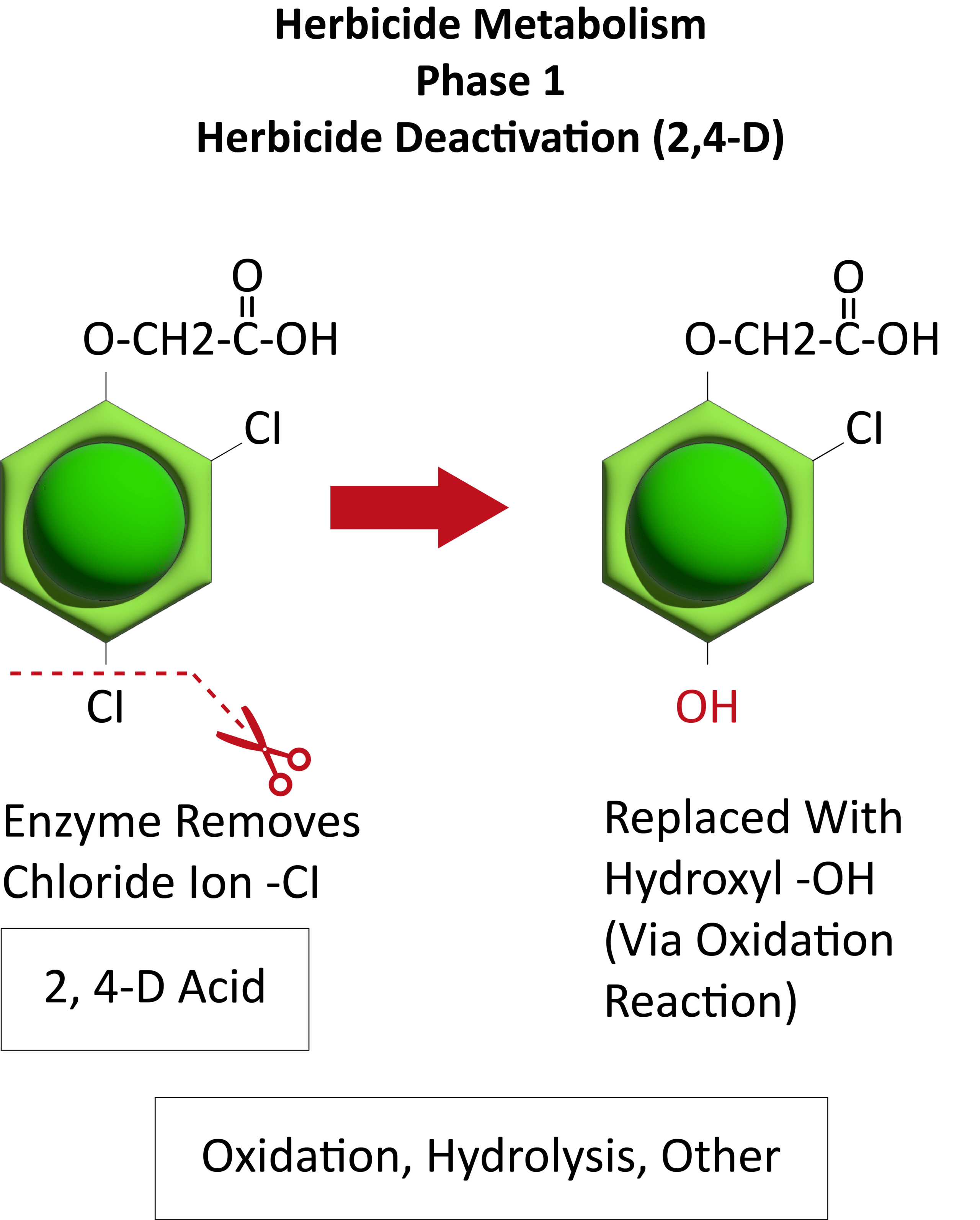

- Glyphosate readily controls grass cover crops, while tank mixtures (e.g., glyphosate + dicamba or 2,4-D) are needed to control legume cover crops.

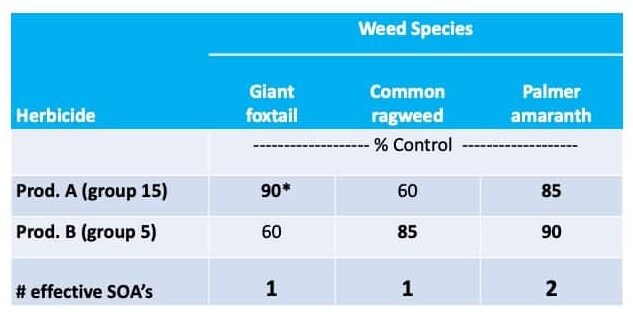

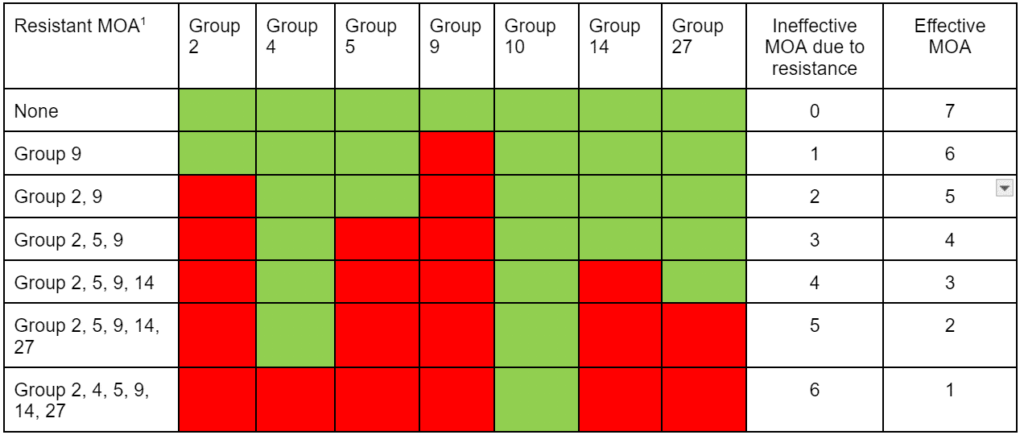

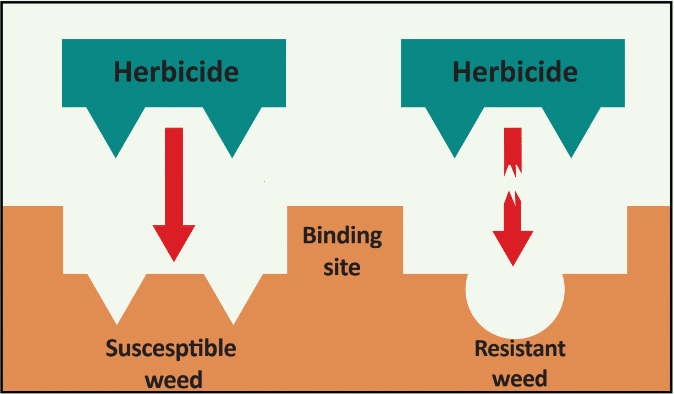

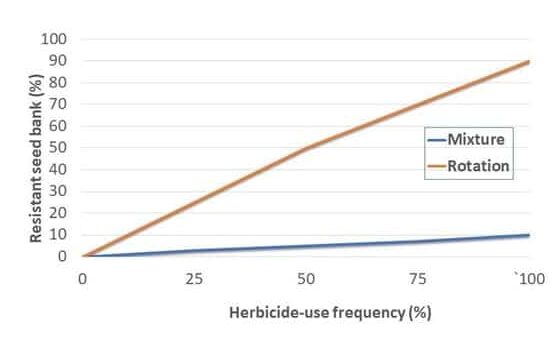

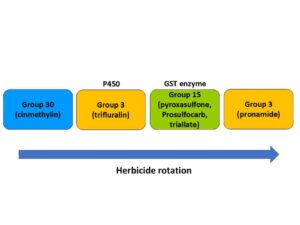

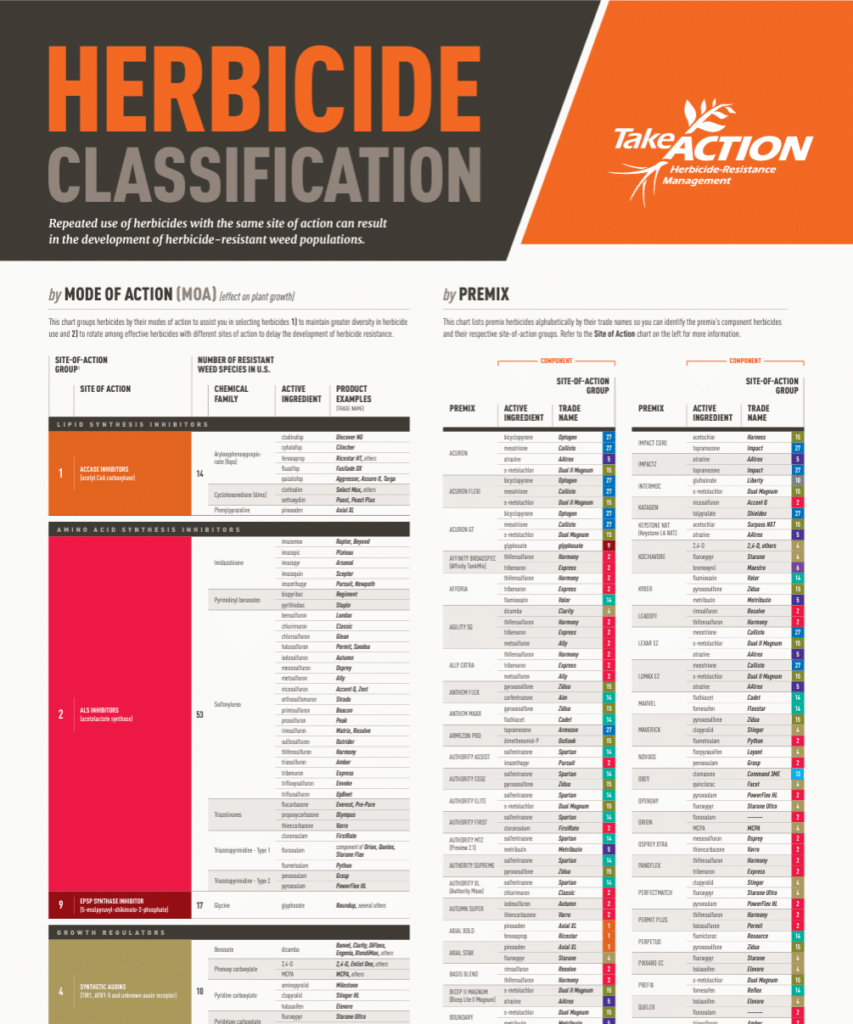

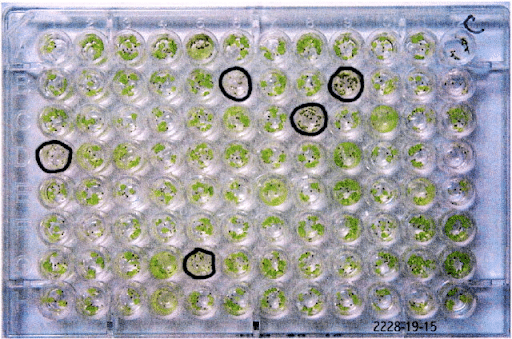

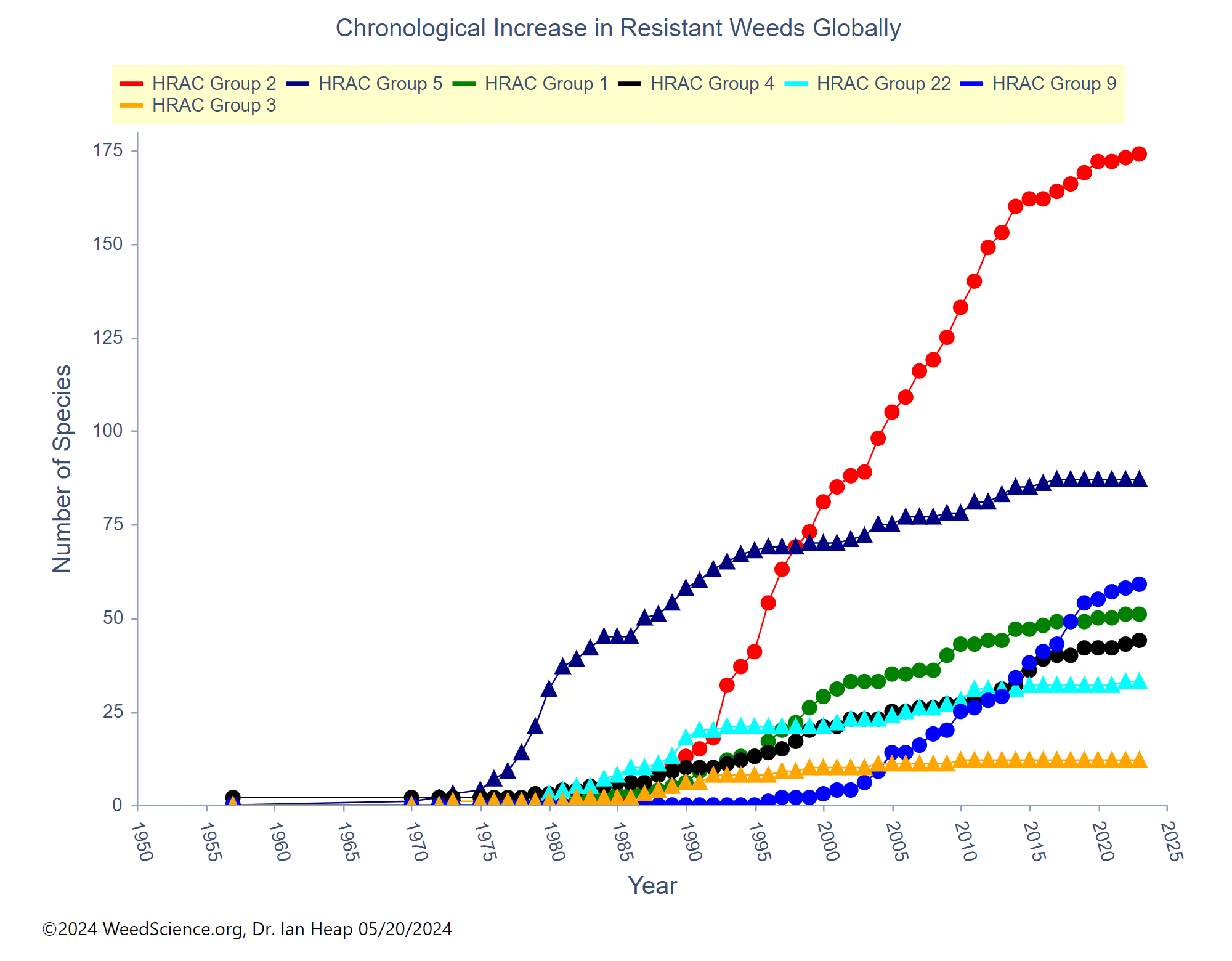

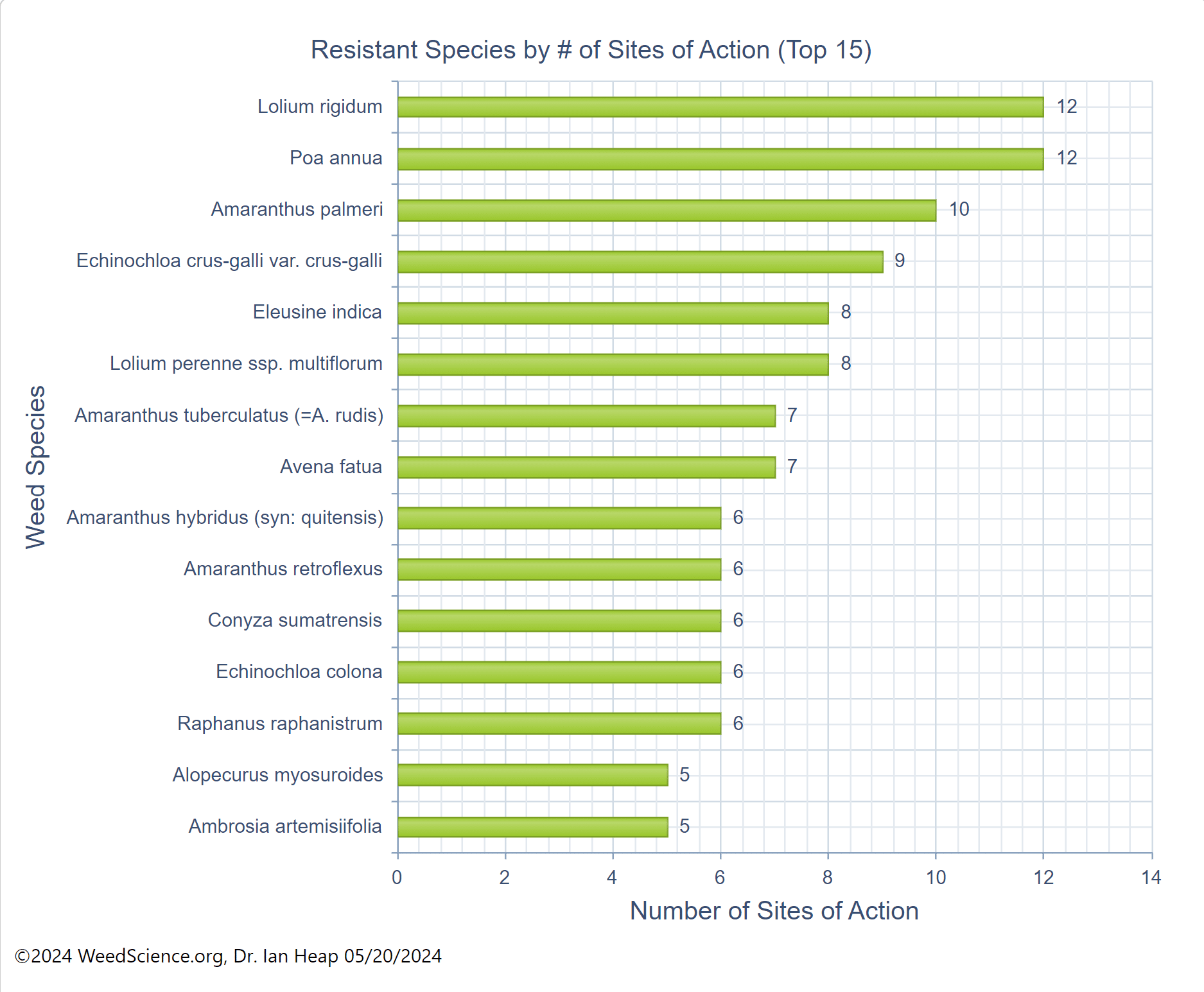

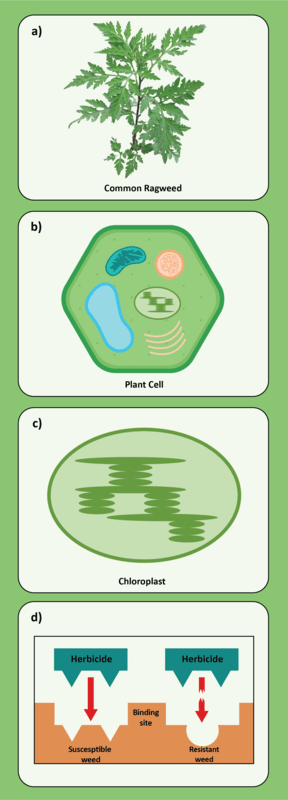

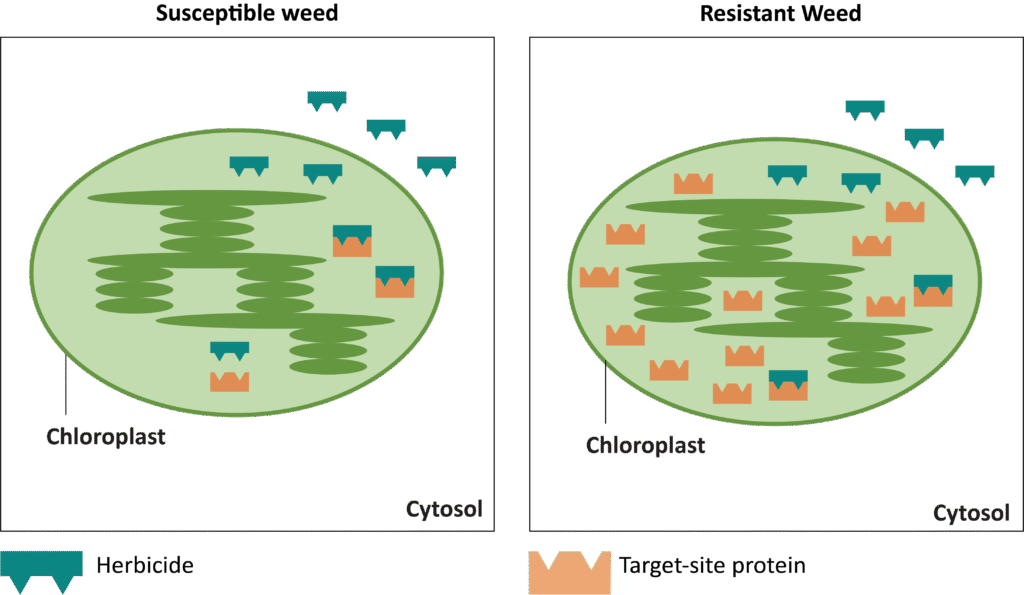

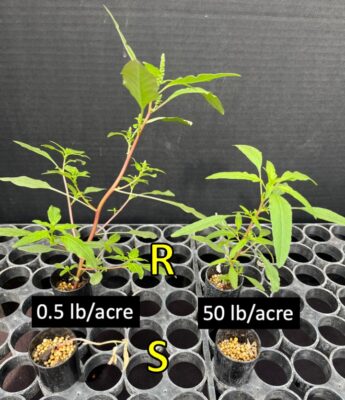

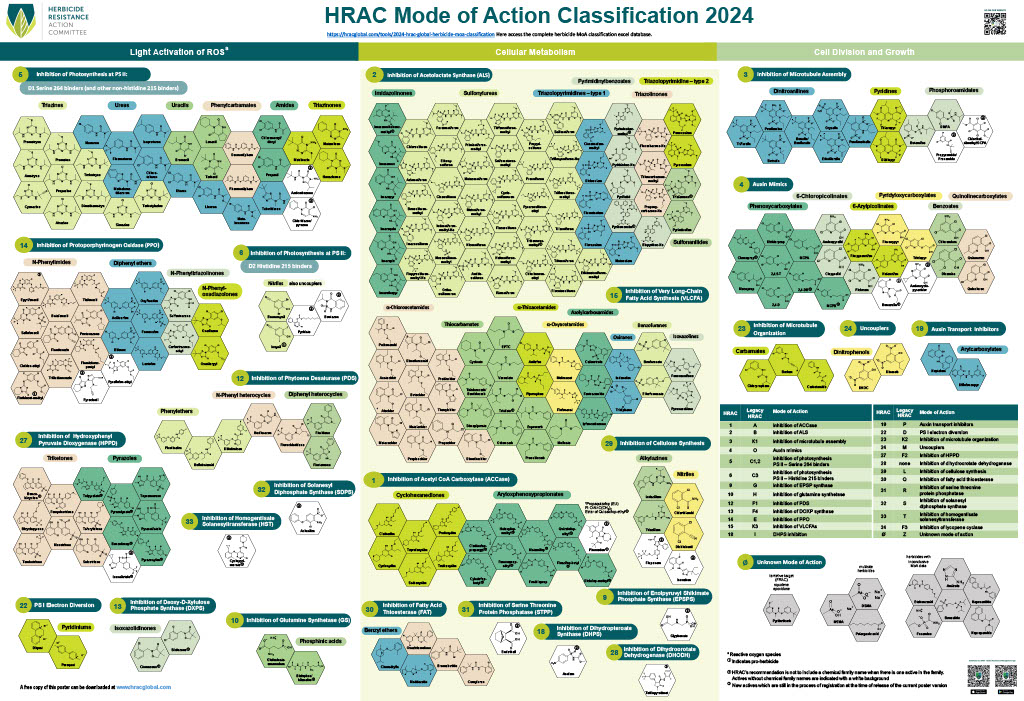

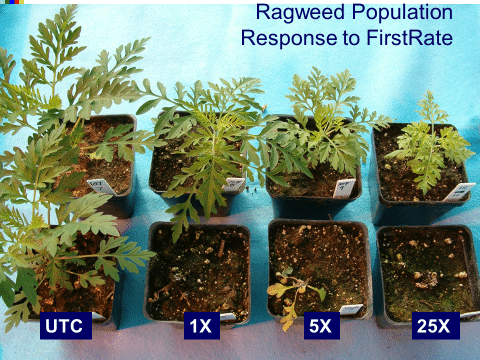

- For cover crop species in which herbicide resistance has been documented (e.g., annual ryegrass), be prepared to use a different termination method or an effective herbicide that relies on a different mode of action (MOA) to completely terminate the cover crop.

4. Planting Green / Planting into High Residue Cover Crops

“Planting green” is the practice of planting a cash crop into a living, green cover crop, which is either terminated at planting or sometime after planting. The practice comes with the benefit of a longer cover crop growing season and increased biomass that can enhance weed suppression. But it also comes with some challenges, such as planting into a high-residue environment and avoiding nutrient availability tie-up from a decomposing cover crop.

The videos below help explain how one farmer uses planting green to enhance his operation in Maryland.

Cash crop planting can be more challenging in heavy cover crop residue and particularly when planting green. Because of the need for weight, down pressure, and additional residue management, planters are generally preferred over grain drills for establishing larger-seeded row crops. To be successful, several modifications are often made to standard no-till planters. Here is a summary of suggestions from some no-till experts.

- Check planter adjustment in every field. Differences in soil moisture and residue type and amount require constant monitoring and making small changes.

- Run the planter level or slightly nose up.

- Planters should be equipped with adjustable down pressure. Older planters used coil springs to control down pressure, but air and hydraulic downforce is now common to control each row independently and on the fly. Adjustable downforce helps maintain ground contact and it alters and holds the soil structure next to the furrow.

- Add fluted coulters to the front of the planter and make sure the coulters are not running deeper than the bottom of the double disk openers. Other experienced no-tillers don’t recommend coulters ahead of the row units. Something to investigate more. You could also consider using specialized residue slicers (e.g., Pequea Planter) that cuts the seed zone residue without disturbing the adjacent plant material.

- Row cleaners are a valuable tool to include but can be more difficult to add on narrow-row planters. Including adjustable down pressure to the row cleaners is important and controlling this from the tractor cab is a major advantage. The row cleaners can be barely touching the soil where they comb the residue and arrange it to be more easily cut or with more down pressure, you can aggressively move residue and even soil. Some brands of row cleaners are better in preventing entangling of residue, especially important when planting green.

- Keep opener discs sharp and in good condition.

- Some farmers replace OEM gauge wheels with alternative wheels such as with a reduced inner diameter to help reduce sidewall compaction.

- Add seed firmers to the row units to improve seed to soil contact.

- There are lots of opinions about closing wheels. Many no-till farmers recommend some type of spike-tooth closing wheel. Some use one spike combined with a standard smooth rubber wheel on each row unit. Some spikes are engineered with reverse curved tines which can help close the slit when the soil is moist. There are several different types and brands of closing wheels (major manufacturers include Dawn, Martin, Schaffert, Yetter, etc.).

For roller crimpers, traditional machines are often operated independently from planting. However, at least two companies sell planter attachments designed to help manage higher biomass cover crops. Dawn Biologic sells the “ZRX” zone roller that has row cleaning disks and mini roller-crimpers attached to the frame of the planter, allowing the user to roll/crimp/manage residue and plant in one pass (see images below). In addition, Yetter Mfg. sells the Yetter 5000 “Cover Crop Devastator” as a planter mounted roller crimper also for single pass operations.

Learn how one farmer in Maryland has learned to set up his planter for planting green into thick cover crop residues:

There are several helpful websites and videos that discuss planter configuration in high residue no-till. Here are some examples.

- PA No-till Alliance – Planting into Green Living Cover Crops.

- Planting Green 101: Penn State Research Summary.

- Harborview Farms – Video on Planter setup for planting green – Maryland Eastern Shore

- Penn State – ZRX roller system – floating hydraulic roller crimpers

5. Cover Crop Termination Considerations

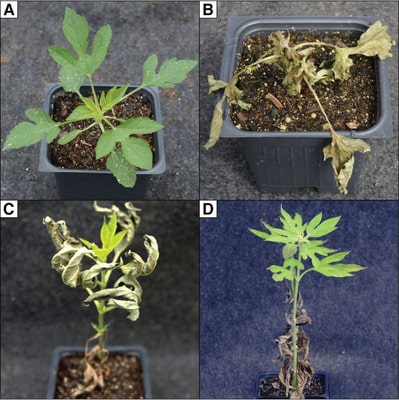

While cover crops can help to suppress weeds, some may also become weeds if not successfully terminated. A cover crop that survives a termination attempt may compete with the cash crop planted into it and impact yields. If a cover crop that escapes termination is allowed to produce seed, those seeds can germinate and become weeds in subsequent cropping seasons. Some potential cover crop problems can be foreseen and mitigated. Keep the following in mind:

- Brassicas that overwinter, such as rapeseed, can be difficult to control with herbicides. Be prepared to mechanically terminate such cover crops, or choose a grass or legume instead.

- A number of factors can reduce herbicide effectiveness, including weather conditions in the spring and herbicide tank mixtures. Be sure to scout the field after termination to ensure the cover crop is successfully terminated.

- Choose only certified cover crop seed from reliable sources to avoid introducing new weeds into the field via contaminated seed that may be hard to terminate. Know what you are buying. Annual ryegrass, perennial ryegrass, and Italian ryegrass can interbreed and are sometimes confused in the trade but have distinct traits.

- Cover crops in the spring can quickly deplete soil moisture. Be advised to watch the weather and expected dry conditions may require changing your cover crop termination timing.

Many termination methods are dependent on timing. If field conditions such as excess spring rain delay or prevent timely cover crop control, consult your local Extension office for termination options and recommendations for addressing the effects of delayed cover crop termination. For example, slightly more N may be applied as a starter in corn to balance the effect of large amounts of cereal rye biomass on soil N levels.

Bottom line: it is crucial to successfully terminate a cover crop. Have a strategy in mind before you plant your cover crops. More than one termination method or pass through the field may be needed if the first method or pass fails.

Cover Crop Termination Factsheet Series

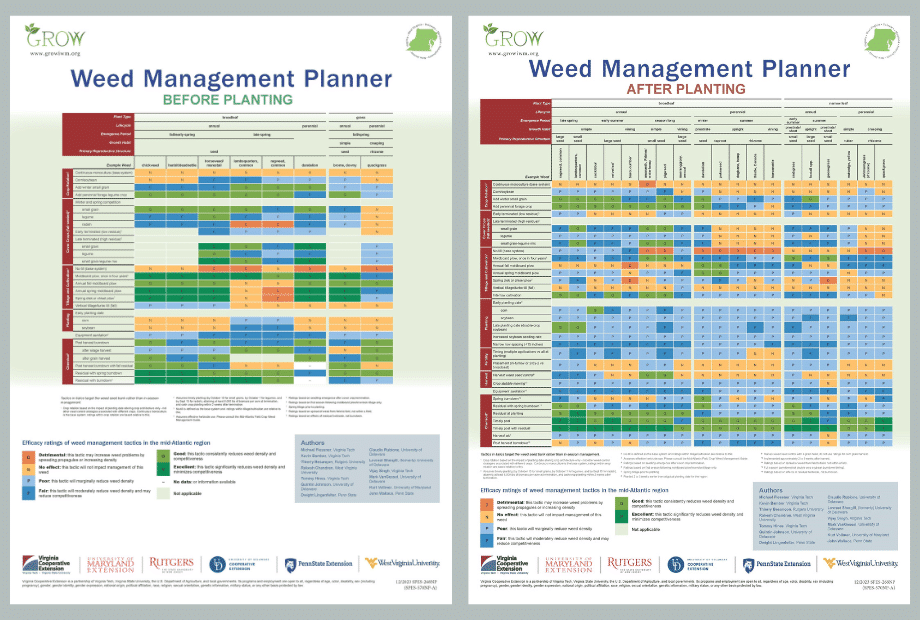

The following four fact sheets cover best management practices for successfully terminating cover crops with weed suppression goals in mind. Use the four buttons below to download each factsheet individually, or use the fifth button to download them all together as a set.

Factsheet Authors

John Wallace, Penn State University

Dwight Lingenfelter, Penn State University

Vijay Singh, Virginia Tech

Michael Flessner, Virginia Tech

Mark VanGessel, University of Delaware

Kurt Vollmer, University of Maryland

Page Authors

William Curran (Penn State University emeritus)

Victoria Ackroyd (USDA-ARS, Beltsville, MD)

Mark VanGessel (University of Delaware)

Claudio Rubione (University of Delaware)

Kara Pittman (Virginia Tech)

Michael Flessner (Virginia Tech)

Resources

Curran, W. 2013. Cover crop rollers for Northeastern grain production. Penn State Extension resource. Available at: https://extension.psu.edu/cover-crop-rollers-for-northeastern-grain-production Accessed 16 April 2019.

Lingenfelter, D and W Curran. 2015. Special cover crop control considerations. Penn State Extension resource. Available at: https://extension.psu.edu/special-cover-crop-control-considerations Accessed 16 April 2019.

Mirsky, SB, JM Wallace, WS Curran, and BC Crockett. 2015. Hairy vetch seedbank persistence and implications for cover crop management. Agron J 107: 2391-2400.

Mischler R, SW Duiker, WS Curran, and D Wilson. 2010. Hairy vetch management for no-till organic corn production. Agron J 102: 355-362.

Palhano, MG, JK Norsworthy, and T Barber. 2018. Evaluation of chemical termination options for cover crops. Weed Tech 32: 227-235.

University of Maryland Extension. 2014. Offing cover crops for weed suppression: Featuring the roller crimper and other mechanical contraptions. Available at: https://extension.umd.edu/learn/offing-cover-crops-weed-suppression-featuring-roller-crimper-and-other-mechanical-contraptions

For more information