Tillage, Cultivation, and Mowing

There is a continuum of tillage systems used throughout North America that ranges from no mechanical disturbance of the soil (no-tillage) to complete soil inversion with moldboard plows with secondary tillage passes to achieve a smooth soil surface. A lot of options exist between these two extremes. High residue systems use a specialized sweep (sometimes called an undercutter) that operate a few inches under the soil surface to cut weeds at the roots but leaves most of the residue anchored at the soil surface. Strip till uses coulters to till a narrow band for the crop row while leaving the rest of the field undisturbed. Ridge till forms ridges the previous season; and at planting, the top of the ridge is scraped off and seed is planted into exposed soil and then throughout the season the ridges are re-established with specially designed cultivators. Chisel plows leave over 40% of the plant residue on the soil surface then the field receives secondary tillage to achieve an adequate seedbed.

Cultivation tools are used after crop planting and do not result is as much soil disturbance. These tools need to be properly adjusted to maximize control while minimizing crop damage.

Mechanical weed control tactics can be an important part of an integrated weed management (IWM) program. Mechanical weed control generally uses some type of mechanical implement pulled by a tractor to physically slice, chop, or uproot small weeds. Mechanical weed control can also include mowing, hand hoeing, or hand removal. This article will briefly discuss some mechanical tactics for weed control including pre- and post-plant tillage and mowing.

Impact of tillage on weed control and seedbank management

1. Tillage prior to planting (pre-plant tillage)

Key Points

- Primary and secondary tillage are used primarily to prepare the soil for planting, but they are very effective in controlling weeds.

- Primary and secondary tillage kills weeds by dislodging roots, burying plants, or chopping them into small pieces.

- Annual weeds, simple perennial weeds, and young weeds are more susceptible to tillage than creeping perennials or large, older weeds.

- Tillage can bury weed seeds deeper than they can emerge but can also bring buried dormant weed seeds to the soil surface.

- Some types of tillage can spread rhizomes, stolons, and tubers of perennial weeds and expand infestations.

- Vertical tillage and strip-till operations typically are not effective for control of established annual weeds or perennials.

Tillage implements vary in their role for preparing fields for planting and in the effectiveness of controlling weeds. Tillage can be divided into two categories: primary and secondary. Both occur between harvest of one crop and planting of a second crop. Primary tillage is most disruptive because it operates 6 to 10 inches deep, breaking up compacted soils and loosening the topsoil layer in preparation for secondary tillage. Examples of primary tillage implements are the moldboard and chisel plows. Primary tillage leaves the soil rough and must be accompanied by secondary tillage to create an acceptable seedbed for planting.

Secondary tillage occurs after primary tillage and is shallower and less aggressive than the primary tillage operation. Secondary tillage is used to break up soil clods left by primary tillage, incorporate fertilizers and manures, create an even seedbed, form or shape beds, or firm soil in preparation for planting. Field cultivators, finishing disks, harrows, and cultipackers are examples of secondary tillage implements.

Minimum tillage implements are used to create a seedbed with plant residues remaining on a large percentage of the soil surface. These implements include vertical and strip tillage tools. Vertical tillage became popular starting back in the early 2000s as a shallow tillage technique in high residue environments typically designed to break up crop residue and/or organic amendments, warm and help dry the soil, and prepare the seedbed for planting with minimal soil movement. Increasingly, it has also been used to help establish fall cover crops by improving seed-to-soil contact during or just after spreading cover crop seeds. Strip or zone tillage typically tills or disturbs the soil only in the row where the crop seed is planted to create a more favorable seedbed. Both of these minimum tillage techniques can help ensure better crop establishment, but typically they do not reduce the need for standard weed control practices.

Finally, tillage options for farmers often depend on soil conditions at the time of operation. For instance, a field that is free of clods and ruts and has very little crop residue may only need one to two passes of a secondary tillage implement before planting even though conventional tillage was the original plan. However, it should be noted that these secondary tillage implements may not uproot and kill established weed seedlings.

A. Primary Tillage

Main Use

Primary tillage, used to invert the soil and incorporate residues. Can potentially invert soil 6 to 12 inches deep.

Strengths

Buries plant residue, uproots small and large weeds, and buries weed seeds. Often the tool is used to plow down a sod or perennial forage.

Weaknesses

Aggressive tillage, prone to erosion and loss of soil quality. Can bring buried weed seeds to the soil surface.

Main Use

Primary tillage, developed to replace the moldboard plow to reduce tillage and conserve some crop residue. Does not invert, but rather mixes the soil layers.

Strengths

Maintains some surface residue and is effective at controlling annual weeds.

Weaknesses

Less effective than the moldboard plow in controlling large weeds or perennials.

B. Secondary Tillage

Main Use

Typically secondary tillage, breaks and incorporates residue and creates a finer seedbed.

Strengths

Concave blades cut/chop weeds and uproot small seedings.

Weaknesses

Not effective on large weeds or most perennials and can spread vegetative structures.

Main Use

Typically secondary tillage, breaks up and incorporates residue and creates a finer seedbed.

Strengths

Effective at incorporating some residue and uprooting small weeds.

Weaknesses

Not effective on large weeds or most perennials and can spread vegetative structures.

C. Minimum Tillage

Main Use

Serves as both the primary and secondary tillage tool, manages residue and creates a plant-ready seedbed.

Strengths

Serves as both the primary and secondary tillage tool, manages residue and creates a plant-ready seedbed.

Weaknesses

Weed control is not the primary purpose. Does not control larger established annuals or perennials.

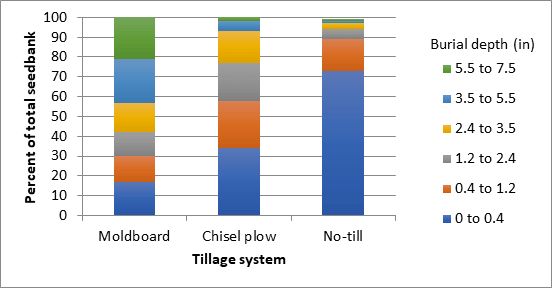

Effect of tillage on the weed seedbank

The effects of tillage practices on weed seedbanks are complex and involve several factors. Tillage affects seed placement, kills seedlings, disrupts plant residues, and alters conditions that influence germination such as gas exchange, seed abrasion, soil temperature, and soil moisture levels. However, seed depth in the soil may be the most important influence tillage has on weed seedling emergence, as this management practice strongly influences the vertical movement of seeds. Primary tillage that inverts the soil can bury seeds to the depth of the plow while returning the buried seeds back to the soil surface. Implements such as chisel plows, disks, and field cultivators do not bury most weed seeds to depths great enough to eliminate emergence. Most seeds within ½ to 1 inch of the soil surface are exposed to sunlight and temperature fluctuations that favor germination and emergence.

As seen in Figure 1, Wisconsin researchers observed a more even vertical distribution of weed seeds after multiple years of moldboard plowing than after multiple years of chisel plowing and no-tillage, where weed seeds were more concentrated at the top of the soil profile in both systems.

Seed size determines the depth from which seedlings can emerge. Smaller seeds do not have enough energy reserves to emerge from more than an inch deep. In general, weed seeds that are buried six or more inches deep will not germinate and emerge, but may survive for several years because of the cooler temperatures and lack of exposure to oxygen, sunlight, and fluctuating temperatures. Some weed seeds buried deeper in the soil profile can remain viable for many years.

2. Post-plant tillage

Key Points

- Post-plant cultivation includes blind tillage using implements such as flex tine harrow or rotary hoe shortly after cash crop planting and inter-row cultivation after the weeds and crop have emerged.

- Blind cultivation is used shortly after the cash crop is planted to control germinated weed seeds and small weed seedlings. Blind cultivation should be repeated about every four to seven days or until emerged weeds are too large for control or mechanical damage to the crop becomes a concern.

- Inter-row cultivation is used after the cash crop and seedling weeds have emerged and is repeated once a week until the cash crop has surpassed the critical period for weed control.

- Most post-plant tillage equipment is not designed to be used in high plant residue situations. If a large number of weeds are beyond the cotyledon stage they can collect on the implements and prevent soil from moving through tines/discs, creating furrows.

- High residue cultivators can control weeds with shallow soil disturbance in reduced till or no-till environments.

- Ridge-till cultivators are specialized high residue cultivators designed to control weeds between crop rows and create a ridge system that can provide more favorable crop establishment, particularly in wet-cold soil environments.

The use of mechanical implements to control weeds after a crop has been planted is known as post-plant tillage or cultivation. There are two types of post-plant tillage intended for weed control: blind cultivation and between-row (also known as inter-row) cultivation. Both tactics are better suited for tilled seedbeds, although some post-plant tillage equipment is available for no-till or high-residue systems.

The success of post-plant tillage requires the use of proper equipment. Many different tools have been developed to control weeds after crop planting. Choosing the right equipment and having it properly adjusted will help take advantage of the ideal times to get into the field and achieve good weed control. The right piece of equipment will more than pay for itself over time by saving a crop when you only have a narrow window to perform the operation.

Blind cultivation controls germinating weed seedlings near the soil surface whose roots are above those of the crop. An implement is “blindly” pulled through the soil (i.e., without concern for driving on the crop rows), dislodging small weed seedlings both in the crop row and area between the crop rows. The initial blind cultivation takes place at the time of cash crop germination and root development, but before crop emergence. Subsequent blind cultivation events may continue after the crop has emerged and are conducted at five to seven day intervals (or as weather allows) for a period of two to four weeks, depending on the crop. Inaccurate operation can result in damage or removal of young cash crop plants, reducing populations and therefore potentially yield. The condition of the soil as well as crop growth stage will dictate whether crop injury is a concern.

The ideal timing for blind cultivation is when weeds are in the white thread stage, known as such because the small seedling resembles a white thread when uprooted (Figure 2). Weeds that have emerged are not as easily killed by blind cultivation. Weather and soil conditions play an important role in the success of blind cultivation. Ideal conditions for cultivation are when the soil is friable (dry to slightly moist but not wet), the weather is sunny and breezy, and no rain is forecast for the next few days. Rain soon after cultivation may allow weeds to re-root and survive.

Cultivating the soil between the crop rows to control emerging weeds is known as inter-row cultivation. Only the area between the crop rows is disturbed; the spacing between crop rows determines the feasibility of using these tools. Guidance systems provide greater precision and allow for increased speed of operation and closer operation near the crop row, while reducing the potential for crop damage.

There is generally more time and flexibility to perform inter-row cultivation than blind cultivation since these tools can control larger weeds than flex-tine harrows and rotary hoes. There are a number of different types of shanks and sweeps that are available for between-row cultivation depending on how it is used. Shanks connect the sweeps to the body of the cultivator and are designed in various styles. The shanks range from rigid to flexible, allowing the sweep to remain stable or to vibrate through the soil. The type of weed control needed determines what type of shank should be used. Most cultivators should be used on weed seedlings. Once weeds have more than one or two true leaves, they are harder to dislodge from the soil and are prone to wrapping around cultivator shanks.

Shields can be used to prevent soil from moving into the crop row and burying small crop plants. Once the crop’s stems become rigid, cultivators can be adjusted to move soil into the row around the base of the crop to bury smaller weed seedlings.

Cultivators are available for use in high plant residue environments, including use in fields with cover crop residue on the soil surface. Cultivators are designed for specific situations including in no-till, ridge-till, or tilled fields with a large amount of plant residue. Initially, they were more commonly used in ridge-till systems and designed with a moderate crown and V-shaped wings to throw soil, forming a “ridge” at last cultivation. No-till sweeps have been designed with a flat crown for less soil disturbance. These types of cultivators typically have one large sweep between two rows compared to three or more found on conventional cultivators. No-till sweeps are designed to sever plants under the soil surface, so they are more effective on larger seedlings (two to three inches tall or in diameter).

Several mechanical weed control tools have been developed for higher value horticultural crops (Table 2). These tools are designed to control small in-row weeds or weeds right next to the crop row in tilled seedbeds. Spyder, torsion, finger, spring hoe, and basket weeders are examples of tools for use where effective herbicides are not labeled, to reduce use of herbicides, or in organic production. These tools require precision, which may mean using smaller equipment or slower operational speeds. Research has shown that “stacking” the use of some tools such as torsion and finger weeders and the row harrow in a single pass can improve or even synergize control efficacy, but the potential for crop injury can also increase. These specialized tools are less common in agronomic crops.

Precision application

Various guidance systems also are available to ensure operating accuracy and allow for faster operating speeds. Technology that can allow precision guidance with numerous field operations (including cultivation) is developing quickly. Faster operating speeds reduce operation costs. Sensory guidance systems provide more effective weed control and reduce crop injury from cultivation or other operations.

Table 2. Tools for blind and inter-row cultivation and some specialty tools.

A. Blind Cultivation

Main Use

Blind cultivation.

Strengths

Controls seedlings in the white thread stage. Operates at relatively high speed.

Weaknesses

Less effective at controlling emerged weeds. Timing is critical for weed control and to avoid crop injury.

Main Use

Blind cultivation.

Strengths

Controls seedlings in the white thread stage. Operates at relatively high speed. Considered more aggressive than flex-tine weeders. Some models can handle some crop residue.

Weaknesses

Less effective at controlling emerged weeds. Timing is critical for weed control and to avoid crop injury.

B. Inter-Row Cultivation

Main Use

Most common tool used for inter-row cultivation. Can be configured with several kinds of shanks to improve performance.

Strengths

Can effectively control small annual weeds in tilled soils. Most effective when the soil is dry.

Weaknesses

Less effective on larger weeds and perennials and requires a relatively fine seedbed. Less effective in wet soils.

Main Use

Designed to operate in no-till or reduced tillage environments. Typically equipped with a single wide sweep rather than multiple shanks.

Strengths

Can effectively control small and medium sized annual weeds. Can also suppress perennials.

Weaknesses

Less effective on most perennials. Requires larger tractors with more horsepower to operate.

Video

3. Mowing

Key Points

- Mowing is a mechanical tactic that can be used to suppress certain weeds.

- Mowing is most effective at reducing biomass and seed production of annual broadleaf weeds and is less effective for managing grasses and perennial weeds.

- Mowing should occur when weeds are beginning to flower, rather than in the vegetative stages.

- While tillage is a better choice for perennial weeds, repeated mowing can reduce vegetative carbohydrate reserves and weed seed production.

- Multi-row inter-row mowing units are commercially available for use in row crops.

Mowing is a mechanical weed management practice that physically cuts or chops weeds close to the soil surface, which can reduce both the competitive ability of weeds and weed seed production. Repetitive mowing over the course of a season can also deplete the carbohydrate reserves of perennial weed species, which reduces plant vigor the following season. In general, mowing is more effective at controlling annual broadleaf weeds, which have growing points well above the soil surface. Grass species and perennial weeds with growing points near or below the soil surface are stressed by mowing but will readily regrow. In contrast to tillage, mowing maintains surface residues, thus reducing soil erosion.

Sickle-bar, rotary, and flail mowers are commonly used to harvest forage crops and for vegetation management of non-crop areas. Operators of all of these mowers should avoid “scalping” the soil, a practice that dulls the blades and exposes soil, creating an opportunity for unwanted weeds to establish. Mowers should also be cleaned regularly. They can move weed seeds, rhizomes, and stolons from infested areas to new areas.

Mowing will not destroy weed seeds. If seeds have already begun to form at the time of mowing, they will continue to mature and develop viable seeds, so repeated mowing is needed to prevent weed seed development. Repeated mowing also has the effect of reducing overall plant height, which can also limit the spread of seeds that rely on wind dispersal. Mowing is not effective on low-growing weeds.

Though not a common practice, researchers have explored using mowing within field crops to reduce weed pressure between crop rows. Inter-row mowers generally contain multiple mowing units with rotary mowers. Companies that have recently begun marketing inter-row mowers include Row Shaver, Great Bend, KS and R-Tech Industries, Homewood MB, Canada.

In research plots, inter-row mowing reduced weed biomass by up to 60%. Similar to other mowing in non-crop areas, annual broadleaves were more susceptible to mowing than annual grass or perennial species in these studies. Mowing twice (once at the V2 stage followed by mowing at V4 stage) was the most effective approach.

Mowing can be an important component of an overall weed management approach. While mowing field crops is not widely practiced, timely mowing of field borders and roadsides can reduce weed seed production and prevent encroachment of weeds into the field. Like all weed management strategies, timing is important for maximum effectiveness.

4. Harvest weed seed control

Harvest weed seed control involves collecting weed seeds at the time of grain harvest and then killing, removing, or concentrating them with various methods (Flessner et al. 2019). These tactics are only successful for weeds that retain most of their seeds at the time of cash crop harvest. Weed seeds that shed prior to grain harvest are not impacted. In general, HWSC is best suited for grain crops that use a grain platform header. There are several types of HWSC being used commercially or tested in research trials. For information on seed mills and other HWSC tactics visit this GROW webpage on Harvest Weed Seed Control.

Picture credits: All pictures are the property of https://www.sare.org/resources/steel-in-the-field/ except “Vertical tillage” whose credit belongs to Lourdes Rubione.

For more information on mechanical weed control, click on the button below:

Author

- William Curran, Penn State (Emeritus)

- Annika Rowland (Mowing section)

Editors

- Victoria Ackroyd

- Michael Flessner

- Kreshnik Bejleri

- Eugene Law

- Lauren Lazaro

- Steven Mirsky

- Claudio Rubione

- Mark VanGessel

Reviewers

Eric Gallandt (Mowing section)

Resources

- Penn State, Rutgers University, University of Delaware, USDA-Beltsville, Virginia Tech & West Virginia University. A Practical Guide for Integrated Weed Management in Mid-Atlantic Grain Crops. Chapter 13 & 14, “Mechanical Weed Control: Pre-Plant & Post-Plant.” Accessed September 2021. https://growgettingstg.wpenginepowered.com/a-practical-guide-for-integrated-weed-management-in-mid-atlantic-grain-crops/

- Flessner M, Beam S, Pittman K, Everman W (2019) Harvest weed seed control. Virginia Cooperative Extension Bulletin SPES-135-NP. https://resources.ext.vt.edu/contentdetail?contentid=1850&contentname=Harvest%20Weed%20Seed%20Control

- Martens K, Martens MH (2005) In-row cultivation. Rodale Institute. Accessed September 29, 2021. https://lakevieworganicgrain.com/wp-content/uploads/2016/07/In-Row-Cultivation.pdf

- Nebraska Extension. Tillage and no-till systems. Accessed February 15, 2021. https://cropwatch.unl.edu/tillageSustainable Agriculture Research and Education (SARE) (2002) Steel in the field. Accessed September 2021 https://www.sare.org/Learning-Center/Books/Steel-in-the-Field

Citations

- Brown B, Gallandt ER (2018) Evidence of synergy with “stacked” intrarow cultivation tools. Weed Research 58: 284-291 doi.org/10.1111/wre.12309

- Hanna HM, Hartzler RG, Erbach DC (2000) High-speed cultivation and banding for weed management in no-till corn in Applied Engineering in Agriculture 16: 359-365 doi: 10.13031/2013.5220

- Liebman M, Mohler CL Staver CP(2001) Mechanical management of weeds. Pages 139-202 in Liebman, M., C.L. Mohler and C.P. Staver. Ecological Management of Agricultural Weeds. New York: Cambridge University Press.

- Paarlberg PL, Hanna HM, Erback DC, Hartzler RG (1998) Cultivator design for inter-row weed control in no-till corn. Applied Engineering in Agriculture 14:353–361 doi: 10.13031/2013.19394

- Yenish JP, Doll JD, Buhler DD (1992) Effects of tillage on vertical distribution and viability of weed seed in soil. Weed Science 40: 429-433 doi.org/10.1017/S0043174500051869