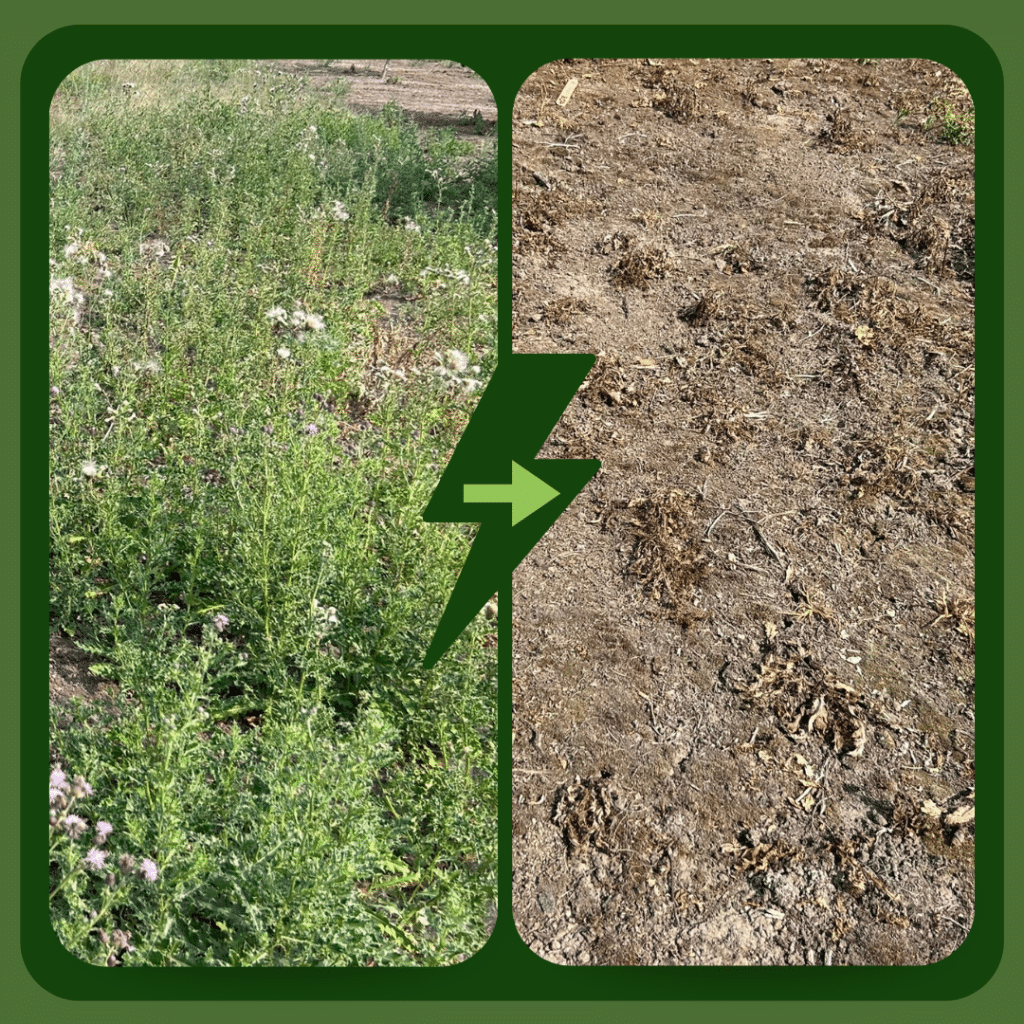

What’s a bigger nightmare than weeds guaranteed to come back each year? Perennial weeds can be particularly irksome for farmers to deal with, but weed electrocution could change that. Oregon State researchers are conducting a long term study in blueberry production to understand how the Zasso XPS and Thor machines affect perennial weed control above and below the soil.

Researchers made three sequential passes with either electric weeder and also integrated other weed management tactics (such as mowing) with their use of weed electrocution. The result was a drastic reduction in yellow nutsedge and Canada thistle populations, says Oregon State Ph.D. student Luisa Baccin. She also found that targeting smaller weeds, using the right applicator for your row spacing, and operating in ideal tillage conditions will help farmers implement weed electrocution safely and effectively.

And although this study examined perennial weeds, Baccin notes that the electric weeders also successfully controlled annual weeds, altogether reducing weed species in the research fields from roughly 12 species, down to just one or two.

Perennial Weed Control

Researchers operated the electric weeders in blueberry fields mid-summer, when Canada thistle and yellow nutsedge were around 6 to 8 inches tall. Both the 24-kilowatt XPS and 30-kilowatt Thor machines achieved similar weed control.

Overall, the electric weeders were able to control up to 94% of the escaped Canada thistle in a field, reducing shoots by 70 to 81% and biomass by 95%. When researchers applied clopyralid at the same time as the first two weed electrocution passes, they reduced Canada thistle biomass by 92%.

We observed that electric weed control works as well as herbicides in reducing the viability of these roots.” Baccin says.

Similarly, pairing weed electrocution with mowing resulted in the greatest yellow nutsedge control (78%), reducing tuber viability by 55%.

Using several weed management methods may be necessary because perennial weeds have extensive root systems, Baccin explains. Even though the electric weeder is able to kill part of the weed’s root system, other parts of the root system can remain untouched and able to produce more plant growth.

For tubers like yellow nutsedge, the best weed control came after mowing when the weeds were small. Mowing weakens the plant first, which might make it more vulnerable to the electric current, Baccin theorizes. Combining both methods puts more stress on the weed, reducing its ability to recover and regrow, especially for tough perennials such as yellow nutsedge.

Can roots hide from electricity? Dr. Moretti’s lab is working to determine just how deep they have to burrow to dodge the damaging volts from the electric weeders.

Understanding Speed and Applicator Size

Effective weed electrocution depends on factors such as speed and applicator size..

Baccin’s research indicates that three weed electrocution passes at roughly two miles per hour every four weeks effectively reduces perennial weeds in a field. Baccin also notes that these sequential passes provide equivalent control to one mowing pass followed by one weed electrocution pass at around 0.6 miles per hour.

The best electricity applicator size will depend on the crop system. For narrow row crops like blueberries, Baccin recommends using a 0.3 meter-wide applicator (equipped on the XPS). The 1.2 meter-wide applicator (equipped on the Thor) achieves more ground coverage and would work best in wider row crops in fruit or nut trees.

“In over two years of trials, we saw no crop damage when using electric weed control correctly,” Baccin adds.

Understanding the Limits

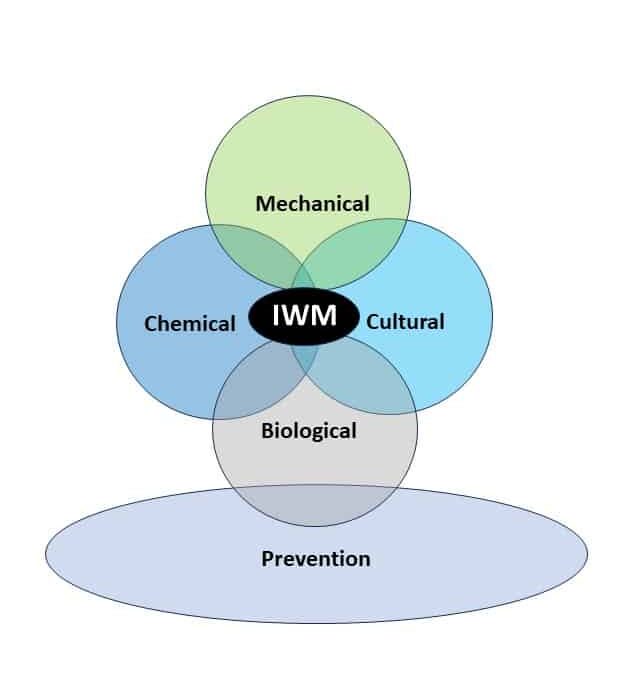

While this research’s findings indicate that electric weed control is a promising tool to suppress nightmarish perennial weeds (especially when integrated with other weed management tactics), there are a few considerations to keep in mind before using one of these devices.

One of weed electrocution’s main drawbacks is the potential for fire in dry conditions. On the other hand, overly wet conditions can reduce the effectiveness of the treatment and make it difficult for tractors to operate safely in the field. For crop safety, it’s important to avoid direct contact between the electrodes and the crop. A good rule of thumb is to only zap weeds when the soil moisture is fit for tillage, Baccin says.

Not all volts reach their target, Baccin adds. Some energy is lost due to factors such as soil moisture, texture, and compaction, as well as plant traits like size, structure, and water content. Because both soil and plant conditions can vary across the field and over time, farmers must adjust the machine’s speed and settings to maintain effective weed control. Weed electrocution’s effectiveness also varies depending on the weed species and density in a field, and perennials can be particularly difficult to eradicate. A field dense with weeds would benefit from first being mowed so that the electricity can zap smaller weeds.

Baccin’s findings overall indicate that when used repeatedly or paired with other weed management tactics, weed electrocution becomes a handy tool in the weed management toolbox in blueberry production.

Visit GROW’s website for more information on weed electrocution.

Article by Amy Sullivan, GROW, and Luisa Baccin, Oregon State; Header and feature photo by Luisa Baccin.