If you aren’t familiar with the growing industry of precision weed applications – known generically as spot spray, smart spray, precision spray or targeted spray technology – now is the time to change that.

“I [see] it as a transformational technology,” says Tom Wolf, spray application specialist and co-owner of Agrimetrix Research and Training, in Saskatoon, Canada. At its best, it should allow growers to spray only the weeds actually present in a field, thanks to boom-mounted camera and data processing units identifying weeds at lightning speed as the sprayer moves across a field. “I think once you’ve seen a field spot sprayed successfully, you don’t ever want to broadcast spray again,” as Wolf puts it.

But the technology comes with its limitations – equipment costs, speed limitations, boom stability requirements and limited nozzle selection, for example. And no one is sure how quickly or successfully it will be adopted by the farmer and applicator community.

That’s partly what inspired University of Wisconsin Extension Weed Scientist Dr. Rodrigo Werle to put together a webinar on the topic, where Wolf and representatives from three ag and technology companies laid out the current state of the precision spray industry – its benefits, costs, challenges and future.

The effort is part of a research grant Werle is working on, in conjunction with Dr. Chris Proctor (UNL) and Dr. Anita Dille (KSU), and funded by the National Corn Growers Association, the North Central Soybean Research Program and One Smart Spray, a precision spray collaboration between BASF and Bosch. “One of our goals is to drive awareness and interest and address questions about this novel technology,” Werle says.

You can watch the full webinar below. Short on time? We’ve boiled it down to three major takeaways that farmers and applicators need to know about the state of the technology — read on!

1. Spot Spray Technology is Here – So Get Up to Speed!

The development of field-worthy, commercial precision sprayers has moved fairly rapidly in the past five years, but farmer knowledge has not kept pace. In a 2021 survey Werle conducted of nearly 130 farmers and crop consultants in the Western and Eastern Corn Belt, roughly a third reported having no real knowledge of the technology.

Even fewer were motivated to embrace it. Half of the respondents said they were “unsure” if they would adopt it on their acres in the future, and over a third reported that they wouldn’t.

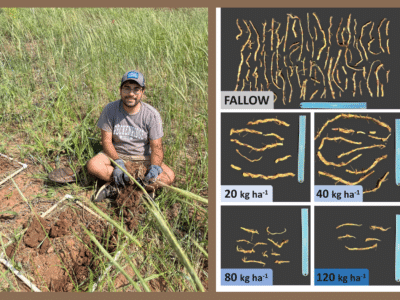

But the commercial race to reach the farmer and applicator is already well underway. The webinar’s line-up of speakers showcased the current range of the industry. William Patzoldt, the director of agronomy for Blue River Technology, showcased the See & Spray Ultimate, co-developed with John Deere. The See & Spray Ultimate now has “green-on-green,” or in-crop, spray capabilities, an upgrade from the “green-on-brown,” or fallow-spray, See & Spray Select system.

Aaron Hunsinger, demand creation manager from Bosch BASF Smart Farming laid out the international collaboration between BASF and German engineering company Bosch, which resulted in One Smart Spray technology. It also allows for in-crop applications and is already in the field in Europe and expected to launch commercially in North and South America in 2024.

Finally, Nadav Bocher, the CEO of a smaller Israeli tech company, Greeneye Technology, unveiled his company’s “retrofit-focused” business model at work in the Midwest and Canada, where they are installing custom, in-crop, spot-spraying booms, plumbing and spray tanks on farmers’ and retailers’ current sprayers. Thanks to the addition of high-powered lights, the system is designed to run both day and night, Bocher says.

All three companies are still actively researching and fine-tuning their sprayers, often with both private and university cooperators, but the commercial wheels are turning. Ag retailers AGCO and CNH have signed on to use One Smart Spray technology. Meanwhile, the See & Spray Ultimate is already commercially available on select John Deere sprayers, and Greeneye Technology is actively working with farmers in 12 U.S. states and one Canadian province.

2. Dual Tank Systems Are Standard and Drive Most of the Benefits

In Werle’s survey, the majority of the responding farmers and crop consultants said they see spot spraying technology as a niche tool that would mostly address late-season weed escapes – a likely underestimation of the technology’s potential, Werle says.

“That was my mindset two years ago, too,” he says. “But working on this project the past two years, I’ve realized this is not a sustainable idea.” Not only does precision spray technology rely on weeds being visible on the ground to cameras, but using chemicals to try to kill large, late-season weed escapes has always been a bad strategy, he explains. “It would be like buying a Ferrari and using it to run chores around the farm,” as Werle jokes.

Moreover, precision spray systems’ increasing sophistication suggests their value will surpass the niche, one-pass tool some farmers are imagining. And this value is driven largely by what has become a standard in current commercial precision sprayers – a dual tank and plumbing system.

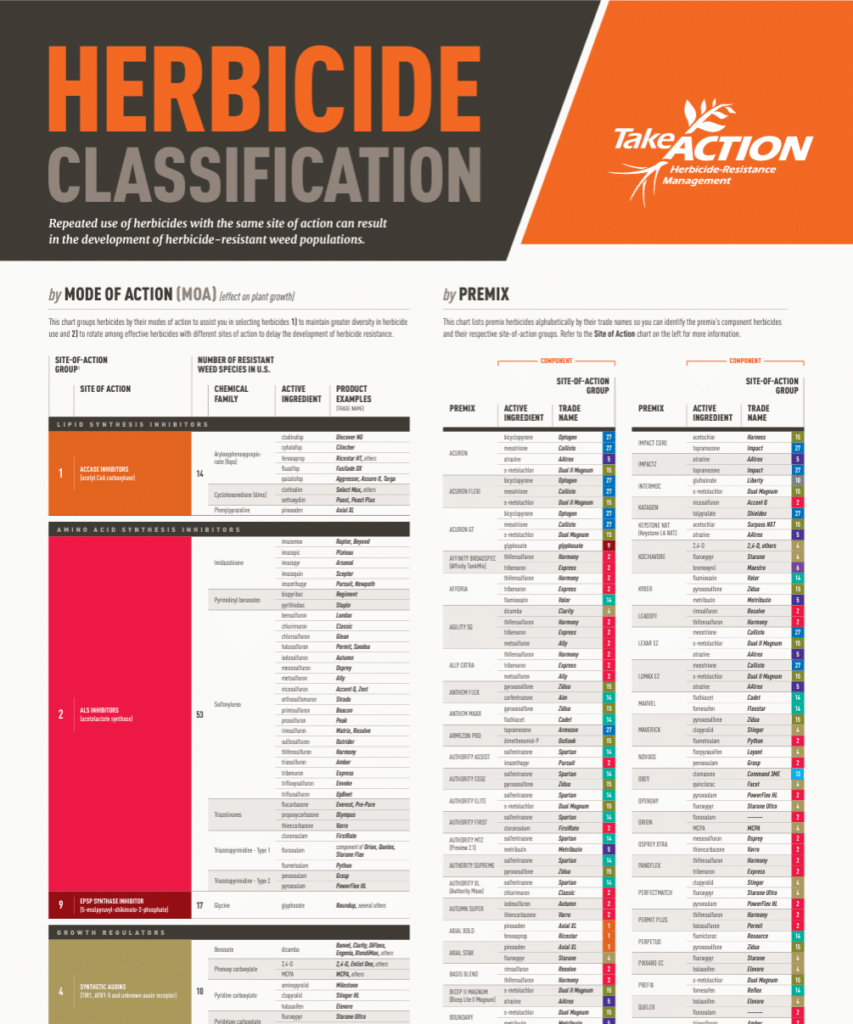

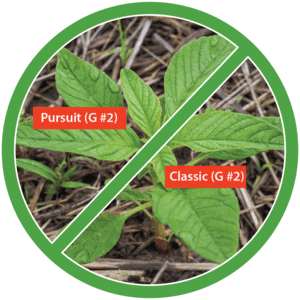

All three companies’ sprayers sport two tanks, one that can be dedicated to residual herbicides (or other types of pesticides entirely) for broadcast applications across the field, and one that can be filled with herbicides for targeted spot spraying – all operating in a single pass. On the See & Spray Ultimate, the tanks and their contents are kept separate “all the way through to the nozzle tips,” says Patzoldt. That means the set-up could theoretically avoid common herbicide antagonism issues and perhaps bypass certain label restrictions on tank mixing herbicides.

The camera systems and precise data generation could also help farmers create and use real-time field maps of their weed pressure and control. That’s a type of mapping that has lagged behind other precision mapping options, such as nutrients and soil type, Wolf notes. (See more on GROW’s efforts to bring public, real-time weed, cover crop and crop mapping to farmers here).

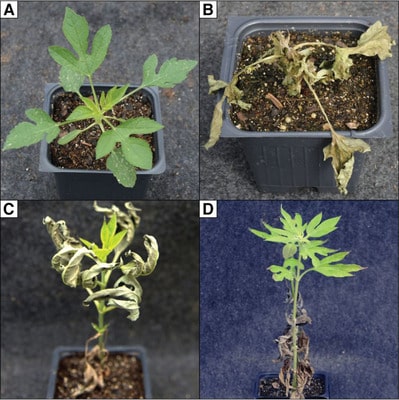

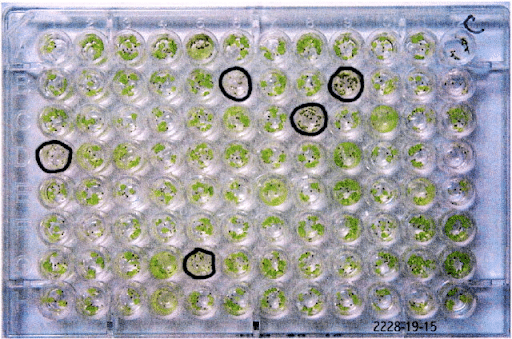

Precision spot spraying accuracy is likely to continue improving, as camera technology improves. Already, Greeneye claims its system produced identical weed control (96%) on broadleaf weeds compared to broadcast applications in tests with the University of Nebraska. And it was only slightly worse on grass weeds (89% control instead of 93% control in broadcast applications). They estimated the spot spraying reduced non-residual herbicide use by 94% in preemergence passes and by 87% in postemergence passes.

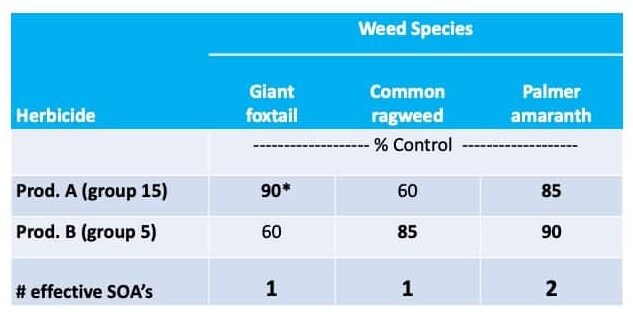

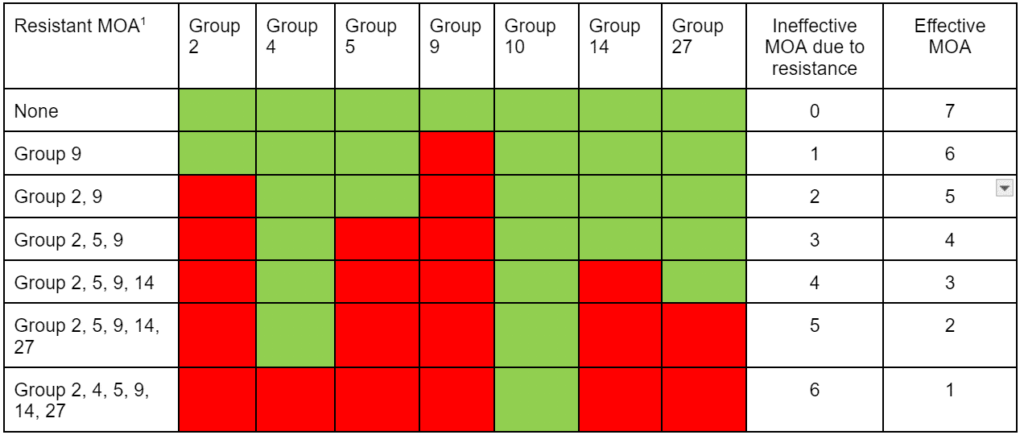

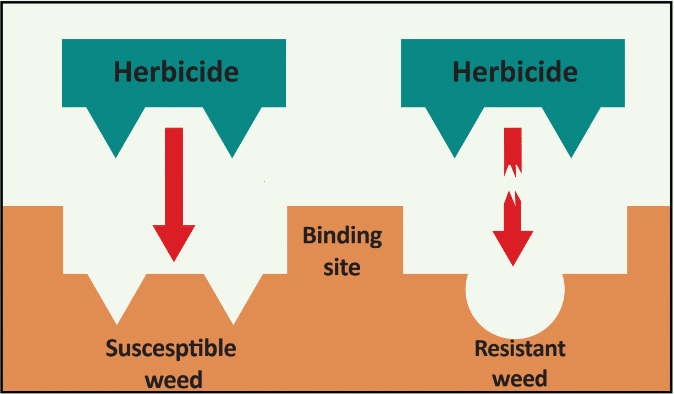

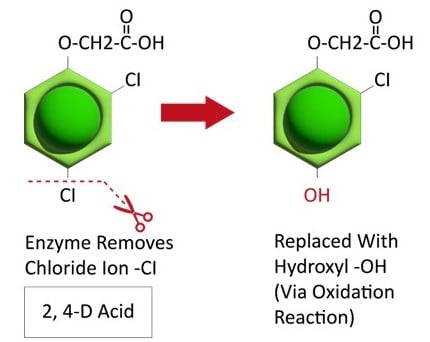

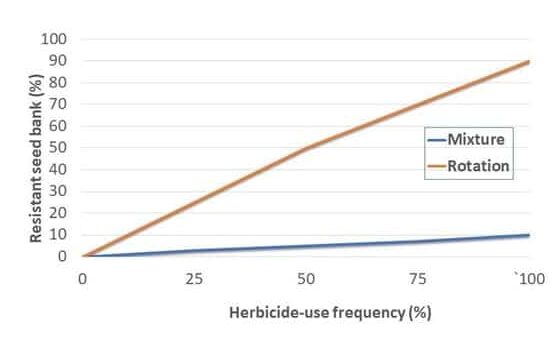

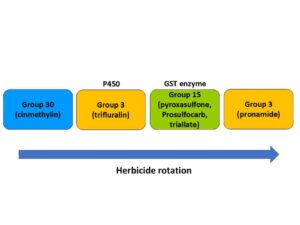

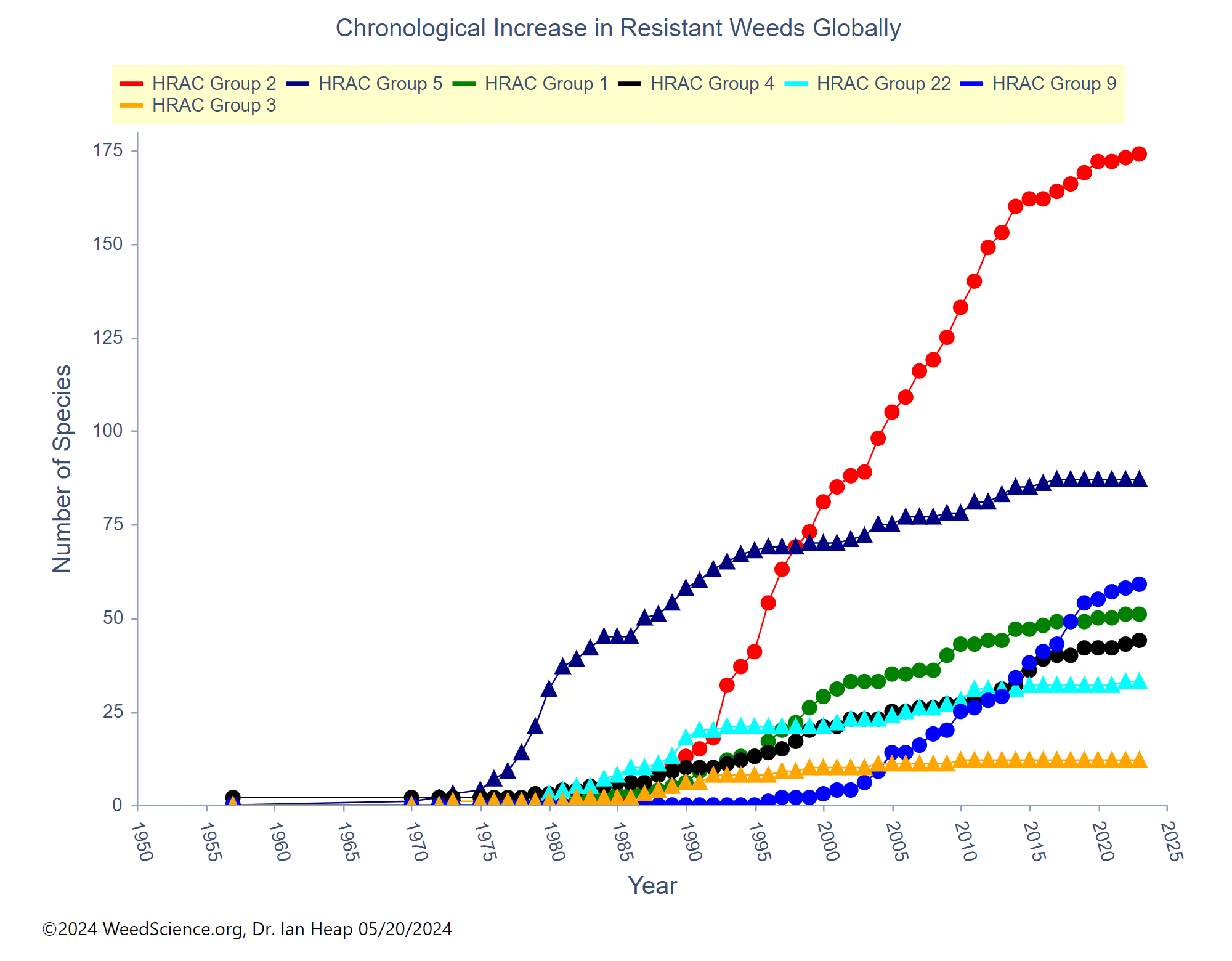

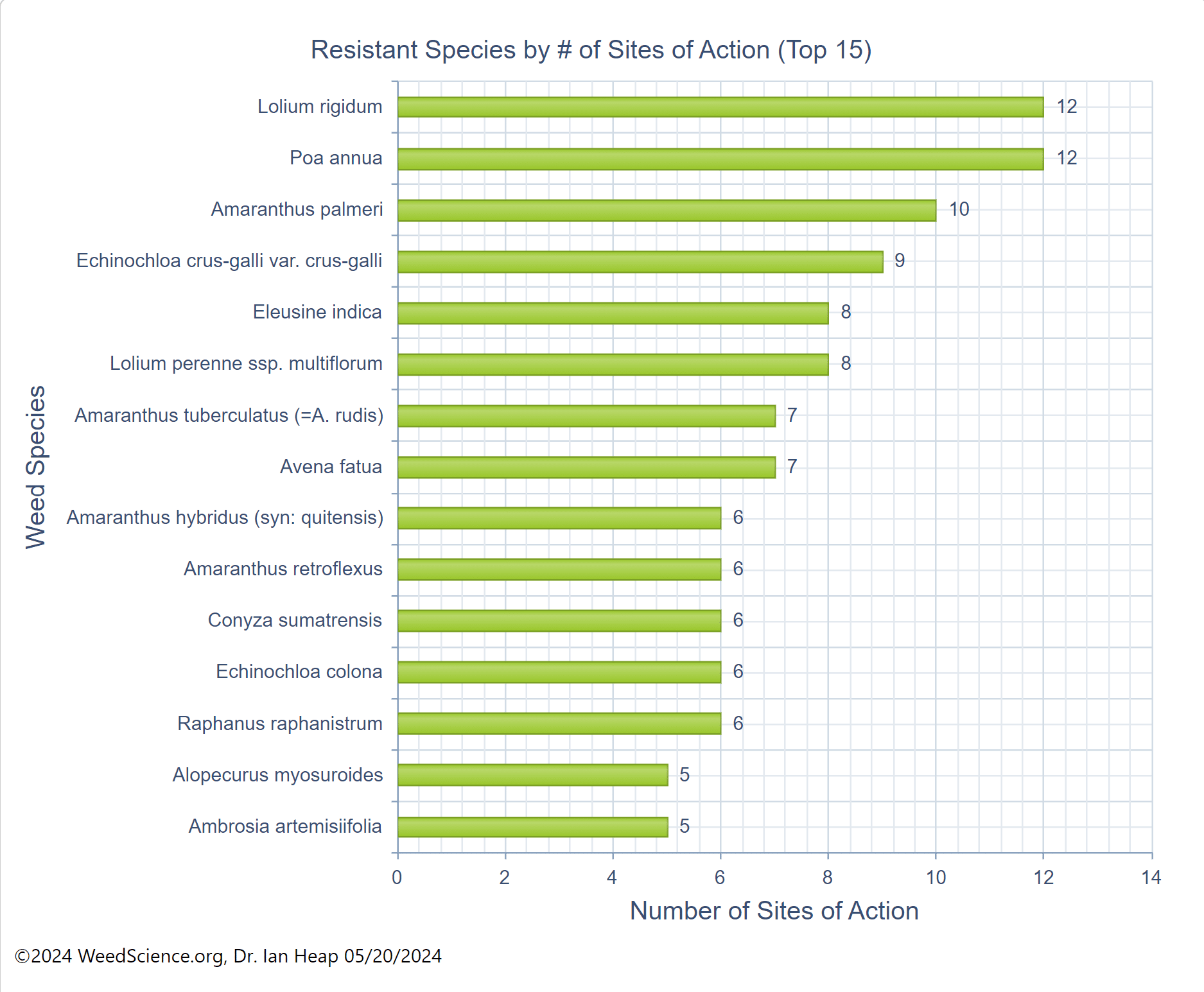

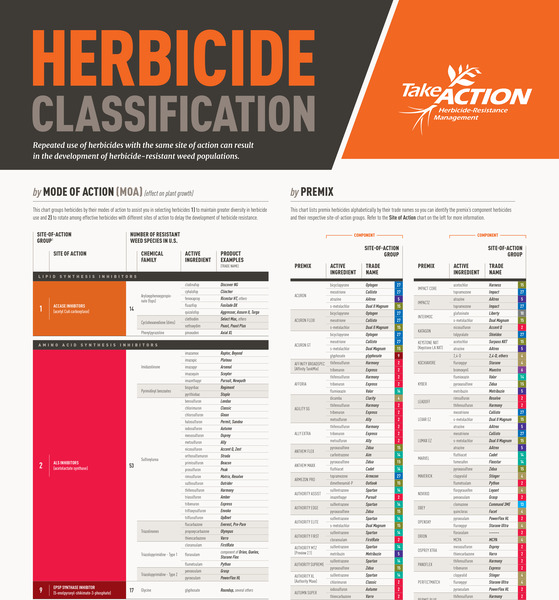

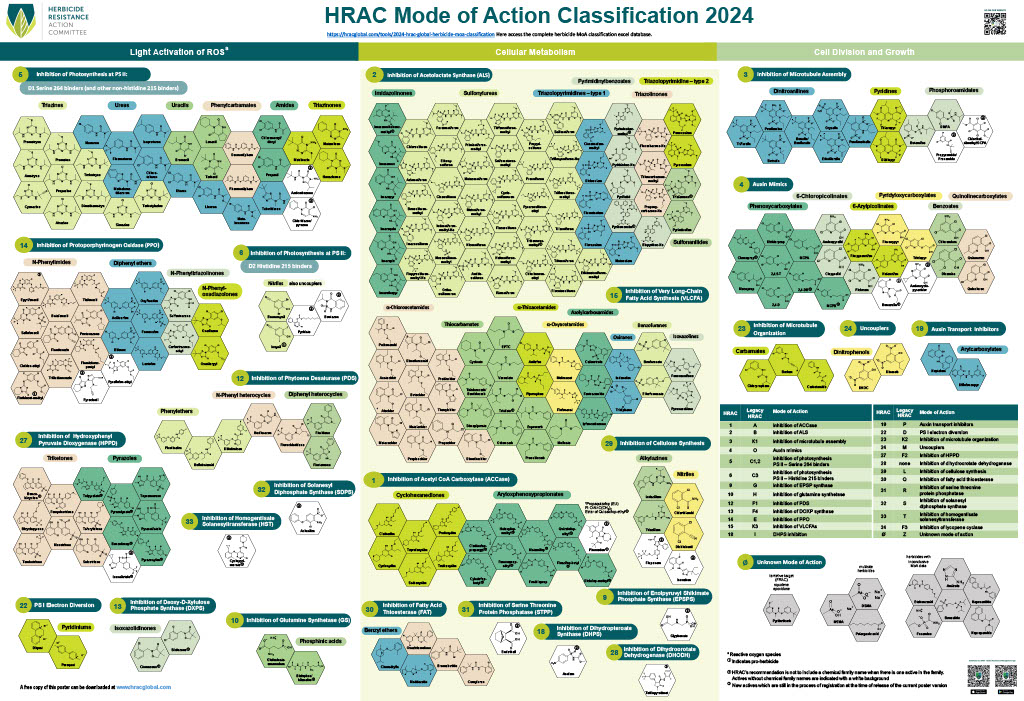

Obviously, numbers like that could create significant chemical savings, Wolf says. He hopes farmers will put that money back into purchasing better, more robust herbicide tank mixes, which will be key to prolonging the life of current spray options, by “buying time” before resistance worsens.

All the precision spray systems also have a similar default mode. If anything obscures the cameras’ view of targeted weeds, the nozzles switch back to broadcast mode, with the aim of avoiding weed misses as much as possible.

And what might compromise the spot sprayers’ weed ID systems? Well that brings us to the next section.

3. Current Challenges Include Boom Stability, Speed, Nozzle Selection & Cost

While precision spot spray technology has made impressive gains in accuracy and efficacy, the machines run into obvious limitations, all three company representatives acknowledged.

For best results, operators will have to keep spray booms as stable as possible. A 10-inch sway in either direction for 95% of your spray time is the target for the See & Spray Ultimate. One Smart Spray recommends staying within 12 inches for their systems, and Greeneye says their cameras will switch to default broadcast mode if the boom moves beyond 50 inches of its set height.

Low boom height is also critical – 26 inches above the ground is the optimal height for the See & Spray Ultimate’s cameras, Patzoldt says. “So if the plant is six inches tall, you need to maintain a 20-inch boom height from the top of the canopy,” he explains.

The nozzles’ accuracy and herbicide savings will be optimized when a low boom height is combined with narrow-angle nozzles, which will prompt the system to use the fewest nozzles (and chemical) necessary to target a single weed, Patzoldt adds.

Keep in mind that the systems’ current nozzle selection – while growing – remains comparatively limited, Wolf adds.

Altogether, these requirements mean that flying along at 18 mph is not going to be an option. See & Spray Ultimate and One Smart Spray top out at 12 mph, and Greeneye Technology’s sprayers shouldn’t go faster than 15 mph. Terraced fields, rolling hills and uneven terrain will all be a challenge, as well.

For now, broadacre row crops remain the priority. Greeneye Technology is currently working only in corn and soybean fields. The See & Spray Ultimate is for use in soybeans, corn, cotton and fallow cropping systems. And One Smart Spray is designed for soybeans, corn, cotton, sunflowers, and canola, with future targets of wheat, barley and pulses.

Exact numbers on the initial costs of these systems remain elusive but are evidently high enough that the companies are currently focused on larger farming operations and ag retailers, where return-on-investment (ROI) is an easier sell. For example, Greeneye Technology is mostly working with growers who farm 2,500 acres or more, as well as co-ops and retailers. The company estimates that a 4,000-acre farming operation could reach their ROI within two years, with an annual recurring savings of $132,000.

Overall, for now, Wolf says the systems’ costs likely put them beyond the realm of small-to-moderate farmers, especially if subscription fee models are adopted. These financial barriers to access, a common feature of developing precision ag technology, are driving GROW’s ongoing work to create open-access, affordable weed identification and mapping technology for the farming community. Read more about that here.

Read more GROW coverage of precision weed management developments here.

Article by Emily Unglesbee, GROW