When Sarah Chu began researching the efficacy of seed impact mills in cotton, she knew it might be an uphill battle. Seed impact mills were originally designed for small grain production, not cotton and its unique harvesting equipment. But with the support of her Texas A&M advisor, Dr. Muthukumar Bagavathiannan, as well as several organizations including Cotton Incorporated, the GROW network, and one of the pioneers of harvest weed seed control, Australia’s Dr. Michael Walsh, Chu discovered that seed impact mills might just have potential for use in cotton production, but not without some caveats.

Chu found that cotton production meets the power and moisture requirements to operate a seed impact mill, and that the impact mill crushed over 98% of weed seeds from gin and bur trash beyond viability. But a post-harvest implement like a flail forage mower is needed to catch any weed seeds left on plants after harvest. Equipment logistics also remain a hurdle ŌĆō if seed impact mills were engineered to outfit cotton harvesters and gins, they might grant farmers more options when it comes to weed control in their cotton productions, Chu concludes.

Understanding Cotton Production

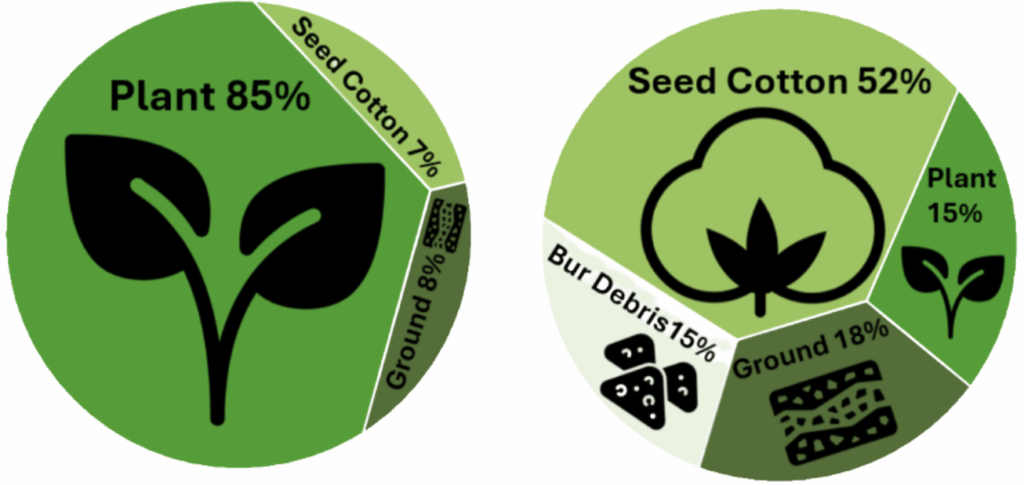

The questions Chu sought to answer all came down to the different types of cotton crop residues, known as ŌĆ£trash,ŌĆØ which emerge from a cotton harvester and would be processed by a seed impact mill.

The different trash types result from the different goals of each harvester. Cotton pickers guide rows of cotton towards vertically rotating heads containing barbed spikes. These barbed spikes only grab seed cotton from the plant as it passes through the cotton picker head. Cotton strippers operate similarly to pickers, but with horizontally spinning rollers that strip plants of their cotton bolls, leaves, and sticks. The cotton stripper then separates the seed cotton from the excess vegetation. Cotton strippers are most commonly used in dry areas where harsh weather conditions require farmers to harvest quickly.

Once seed cotton has been harvested by a picker or stripper, a cotton gin separates the cotton lint from the cotton seed and any remaining plant trash.

In general, cotton stripper trash (sometimes called bur debris) is much bulkier than cotton gin trash (sometimes called gin debris).

Flail forage mowers are used by cotton farmers to cut down cotton stalks after harvest with a cotton picker. While this was the only mower examined in this research, farmers can use any mower for this task. Flail forage mower trash is largely stalks and weeds (sometimes called trash-stem debris).

Chu began this project in fall 2023 by teaming up with Dr. Michael Walsh who was in Texas on a Fulbright Scholarship. The pair set out to find where Palmer amaranth and waterhemp seeds fell during harvest with cotton strippers and pickers, Chu recalls.

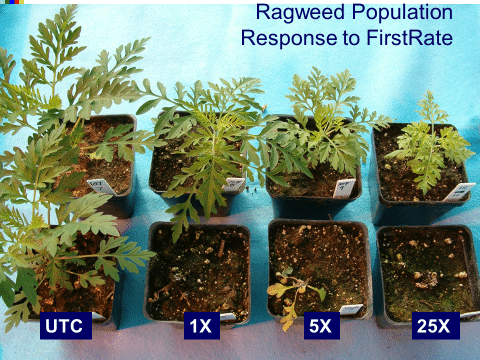

Their research found that 52% of seeds hitched a ride with the seed cotton, and 15% of seeds remained on the weeds after harvest with a cotton stripper. But with over 80% of weed seeds remaining on their plants after harvest with a cotton picker, ChuŌĆÖs research had to pivot. Instead of looking at the seed impact millŌĆÖs effectiveness with cotton strippers and pickers, she looked to evaluate the impact millŌĆÖs effectiveness in cotton strippers, flail forage mowers, and cotton gins.

Previous research at the University of Arkansas already confirmed the presence of several species of weed seeds in cotton gin trash, including palmer amaranth and barnyardgrass. These weeds were also found to be viable for up to two years after the gin trash had been composted. And since cotton gins are the final step in processing seed cotton into lint, theyŌĆÖre also the final chance to target weed seeds.

ChuŌĆÖs revised research targets posed another hurdle: Was it even possible to operate the seed impact mill with each trash type when the impact mills were designed for small grain productions?

Seed Impact Mills Pulverize Weed Seeds in Stripper and Gin Trash

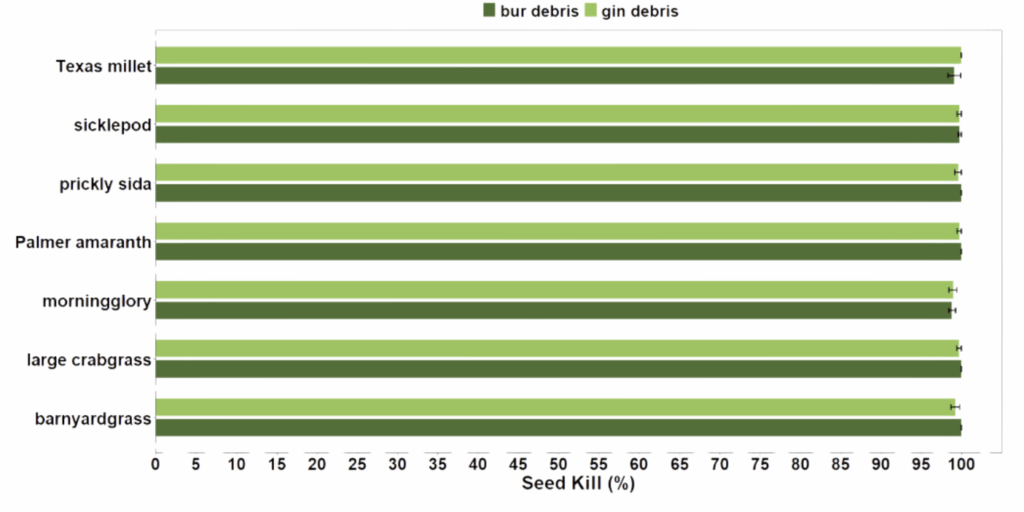

Cotton strippers and gins seemed like a good match for seed impact mills since so many weed seeds end up in their trash. And the findings agreed.

Over 98% of the weed species observed in cotton stripper and cotton gin trashŌĆōTexas millet, sicklepod, prickly sida, Palmer amaranth, morningglory, large crabgrass, and barnyardgrassŌĆōwere pulverized by a stationary Harrington Seed Destructor impact mill.

Getting Picky with the PickerŌĆÖs Results

The cotton pickerŌĆÖs selectiveness meant that just 7% of weed seeds made it into the combine and 85% of weed seeds remained on the weeds after harvest. Combining a post-harvest weed control method like the flail forage mower with the seed impact mill might be able to target the weed seeds still left on plants. However, more research is needed to test that theory.┬Ā

The seed impact mill couldnŌĆÖt handle flail forage mower trash when it was too wet (29% moisture). This trash repeatedly clogged the impact mill and made weed seed viability analysis impossible. ChuŌĆÖs findings align with previous impact mill research in soybean and rice where over 16% chaff moisture clogged the mill. The cotton bur and gin debris had less than 10% moisture.

That doesnŌĆÖt mean that the flail forage mower isnŌĆÖt a contender for harvest weed seed control. ŌĆ£If we could figure out a way to decrease that moisture, it might work then,ŌĆØ Chu says. One potential option would be to use the flail forage mower after giving the weeds and cotton plants more time to dry out.

A Longterm Outlook

The results were unexpected, but promising. The seed impact mill was able to easily terminate weed seeds regardless of gin or bur trash bulkiness, and trash moisture is an obstacle that could be overcome. (Watch the GROW video below to see what ChuŌĆÖs research process looked like for this part of the study).

Chu also found that operating the seed impact mill with cotton gin and stripper debris didnŌĆÖt require more power than wheat or soybean chaff would. Both debris types had peak power requirements under 60 kilowatts, or roughly 80 horsepower. ŌĆ£WeŌĆÖre within normal operating range, which really shows the promise to implement this technology,ŌĆØ she explains.

But thatŌĆÖs not to say that there arenŌĆÖt a few roadblocks. Seed impact mills operate via internally spinning mechanics. High concentrations of lint in cotton debris could catch on these mechanics and make string that clogs the mill. ThereŌĆÖs also the issue of physical logistics. Small grain combines, cotton harvesters, cotton gins, and flail forage mowers are very different machines, and engineers would need to revisit the seed impact millŌĆÖs design to connect these mills to cotton harvesters and flail forage mowers, Chu says.

The results overall suggest that harvest weed seed control could have potential in cotton, even if a lot more work would be needed to outfit seed impact mills onto cotton harvesters, gins, and flail forage mowers. For cotton farmers, that could mean more flexibility in their future weed control options.

ŌĆ£I think of my research as putting a toe in the door,ŌĆØ Chu says. ŌĆ£[This research] is going to go forward beyond me.ŌĆØ

Visit GROWŌĆÖs website for more information on harvest weed seed control and to learn more about the weeds plaguing cotton production.

Article by Amy Sullivan, GROW; Feature photo by Claudio Rubione, GROW; Header photo by Sarah Chu, Texas A&M.