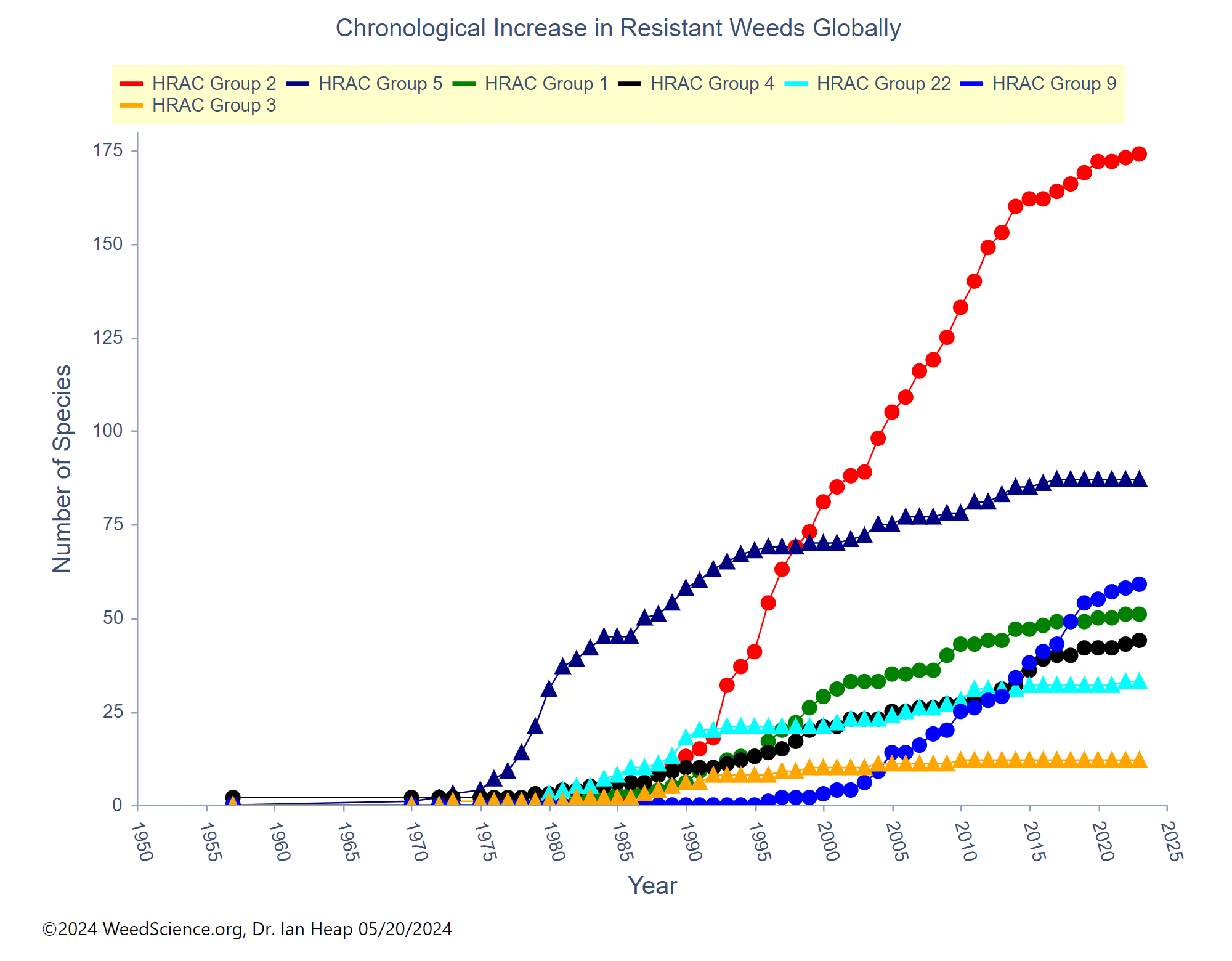

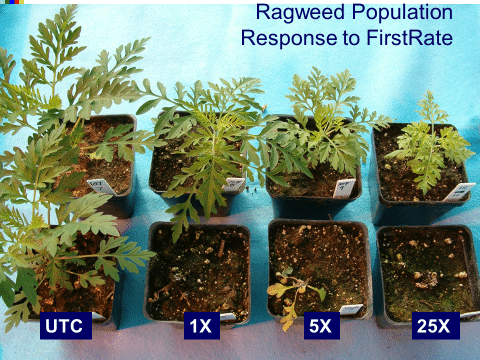

With a rise in herbicide-resistant weeds such as Palmer amaranth and common ragweed escaping in-season control methods, weed scientists are taking the fight to the combine.

Virginia Tech Ph.D. student Eli Russell and his teammates are working to target weed seeds that are captured by the combine during soybean harvest, by testing a type of seed impact mill called the integrated Harrington Seed Destructor (iHSD). Along with his advisor, Dr. Michael Flessner, Russell and his team are studying how well impact mills like the iHSD destroy problematic weed seeds before they are spread back out into the field by the combine, where they can create problems in future years.

(You can see the results of the team’s work with another seed impact mill, the Redekop SCU here.)

Stationary Impact Mill Testing

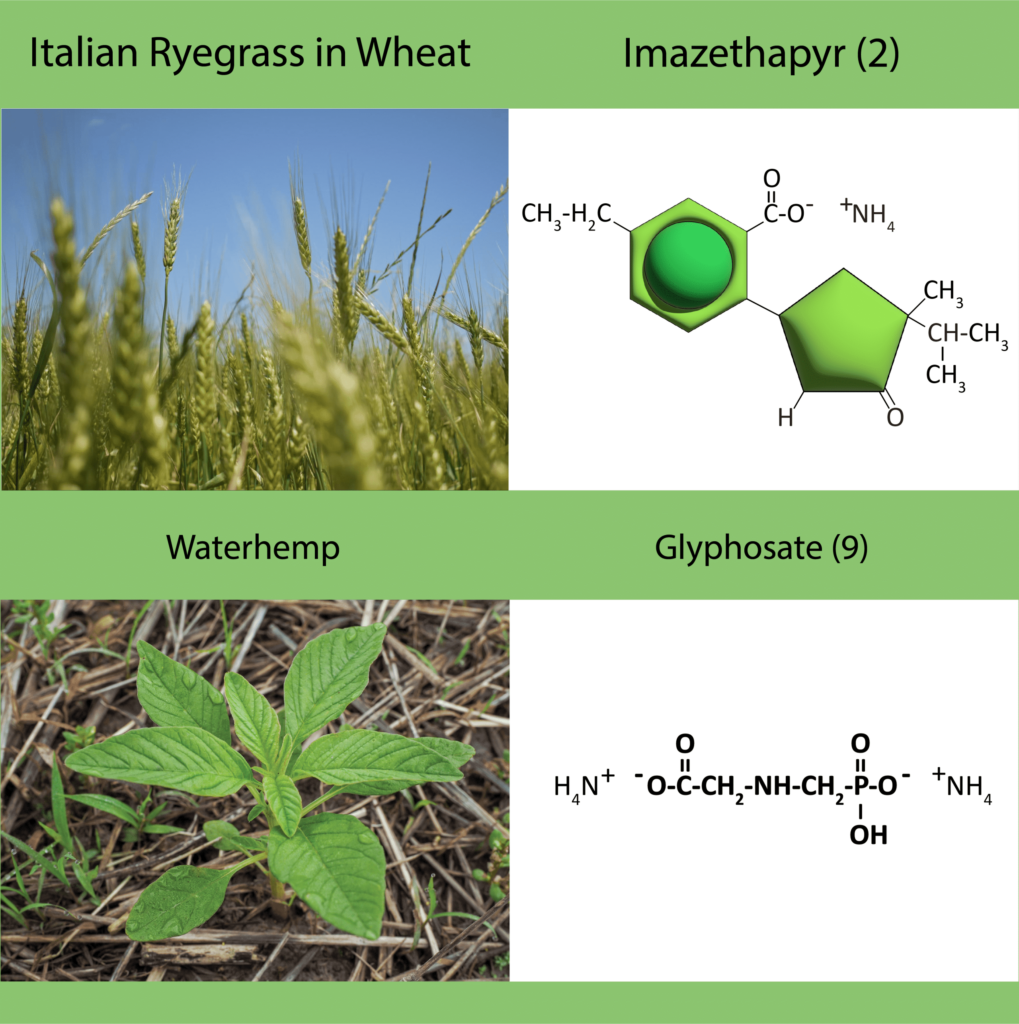

Seed impact mill technology originated in Western Australia, where it was developed to combat herbicide-resistant rigid ryegrass in wheat production. In Australia, it has had positive results in commercial production. However, the U.S. has different harvest conditions, weed species, and crops than Western Australia.

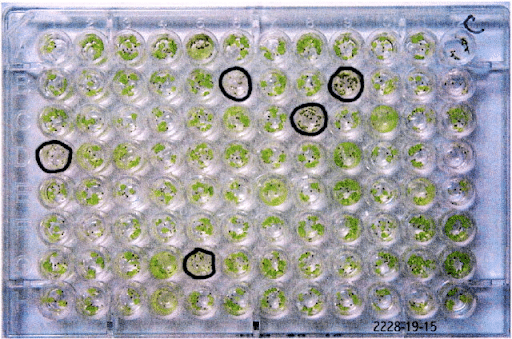

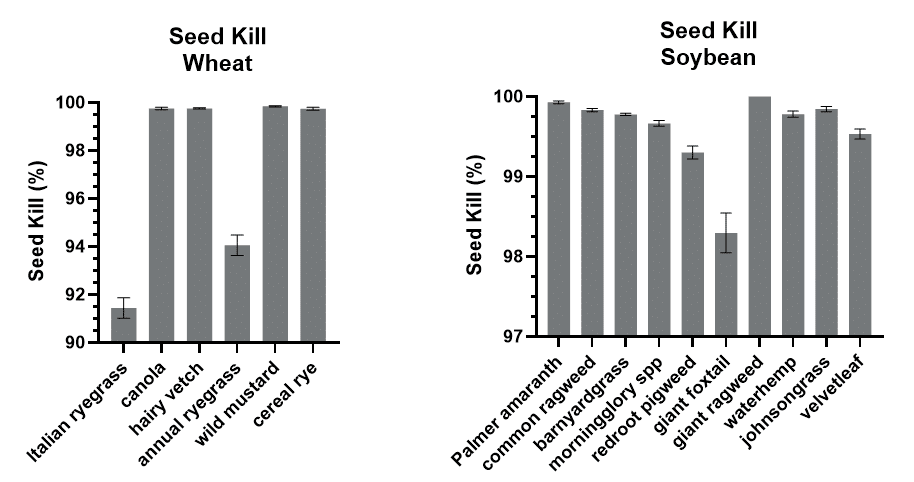

To test the efficacy of these seed impact mills here in the U.S., Virginia Tech has tested a variety of weed species in soybeans and wheat using a stationary test stand version of the iHSD. Testing was conducted with weed-seed-free soybean and wheat chaff. At the time of testing, a known quantity of weed seeds were mixed into the chaff and placed on a conveyor belt that fed directly into the mill. The chaff was fed through the mill and the processed residue was captured in a mesh bag and taken to the greenhouse for further testing.

In the greenhouse, seedling emergence assays were used to determine the seed survival rate through the mill. Results were promising, with researchers seeing high weed seed kill rates of over 98% in soybean chaff and over 91% in wheat chaff.

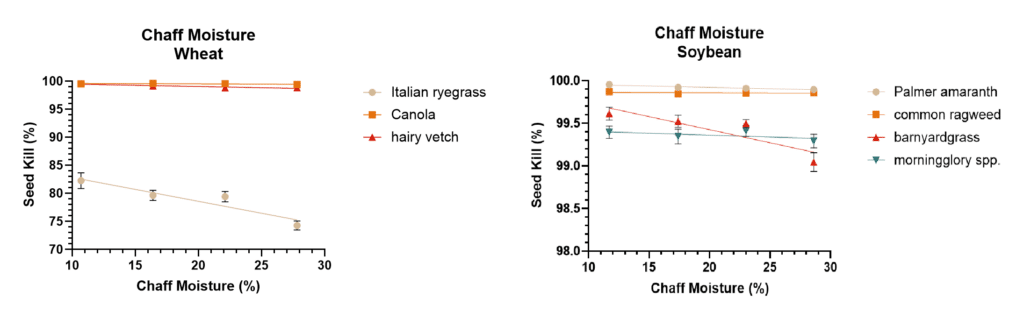

However, harvest conditions are not always perfect. For instance, chaff moisture will likely be higher following heavy dew or rain, and moisture levels in the harvest residue could affect seed kill during harvest. So, to simulate these kinds of harvest conditions, the Virginia Tech team fed soybean and wheat chaff infested with weed seeds through the mill at increasing moisture levels.

They found that, for soybean chaff, moisture has little effect on seed kill of problematic weed seeds in the iHSD, which successfully killed more than 99% of the tested seeds, even at soybean chaff moisture levels above 25%. Wheat chaff moisture also had little effect on broadleaf weeds, with their seed kill rates remaining higher than 98% at high chaff moisture levels (greater than 25%). The exception was Italian ryegrass, which did show a significant decline in seed kill, with kill rates dropping to 74% as wheat chaff moisture levels rose above 25%.

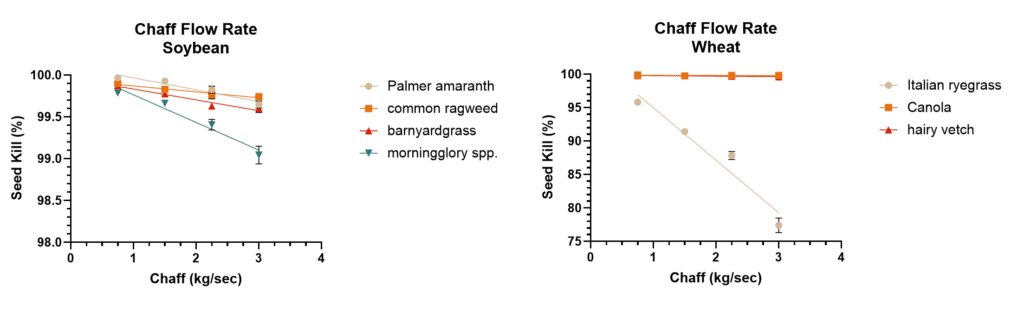

Yield is another factor that could affect weed seed kill rates in seed impact mills. High and low-yielding fields can influence the chaff flow rate into the mill. Typically combine operators will adjust to maximize sieve capacity and keep a consistent chaff flow rate, but these adjustments are not instantaneous. Before adjustments are made, the mill is likely to experience either high or low flow rates, which could impact seed kill.

To test this effect, researchers fed the iHSD a range of soybean and wheat chaff residue amounts, from half of the normal harvest capacity up to double (2X) the standard harvest throughput. As the chaff flow rate increased, seed kill decreased, but it remained above 99% for all tested soybean weed species and wheat broadleaf species even at a 2X throughput. Once again, Italian ryegrass did show a greater decrease in seed kill rates at a 2X throughput, but they remained above 77%.

Overall, the stationary test stand results for the iHSD in soybean production look promising, given the high seed kill rates even in less than ideal harvest conditions.

Taking the Mills to the Field

Observing the iHSD’s performance at the commercial scale was the next step. To do this, the Virginia Tech team braved the dusty harvest conditions to test the iHSD’s efficacy when installed on a commercial combine during two soybean harvests in 2022 and 2023.

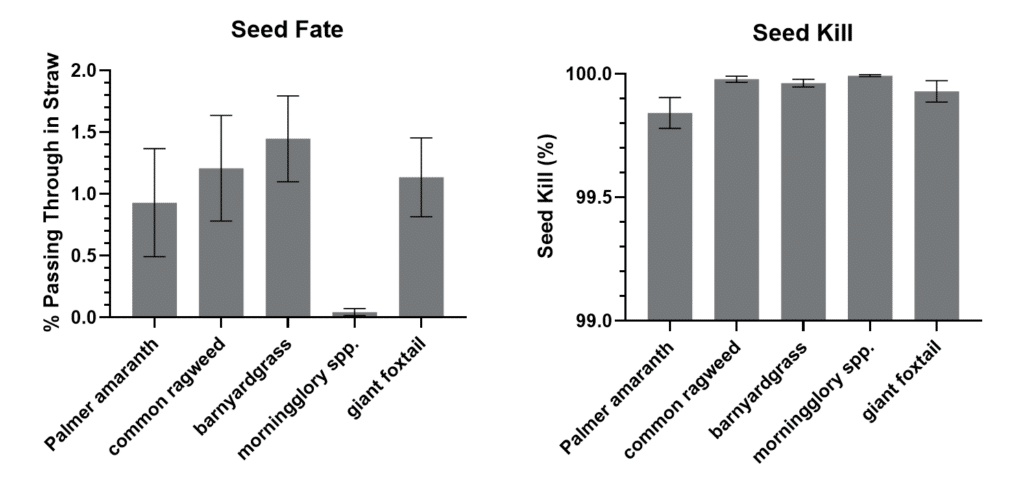

Since seed impact mills only process the chaff fraction of harvest residues, any seeds caught up in the straw fraction could bypass the mill and be spread back into the field. So the first goal of this experiment was to ensure that weed seeds were actually making it to the seed impact mill. Fortunately, the Virginia Tech team’s results indicate that less than 2% of tested species in soybeans are lost in the straw fraction.

Since the vast majority of weed seeds are making it to the mill and not bypassing it in the straw, the next step was determining how well the iHSD actually kills these weed seeds. Results were again promising, with the seed impact mill killing more than 99% of weed seeds that traveled through it during harvest in the field.

Future Research

Even with these promising results, there are still some areas of research that need to be investigated. For instance, understanding the costs of operating the mill, beyond the list price, could influence farmer adoption. The mill requires a newer (at least 2015) and bigger (at least class 8) combine for operation. Additionally, since the mill is powered by the combine, it requires extra power and fuel for operation. Also, some farmers have noticed decreased harvest speed due to the extra horsepower requirements. Additional research is needed to confirm these costs and requirements.

Finally, researchers also hope to learn the long-term impact of seed impact mill technology on weed densities in the field. To do this, the GROW network is partnering with farmers around the country to measure how seed impact mills affect their weed pressures after repeated harvests. Stay tuned to the GROW News Page and Harvest Weed Seed Control Toolbox Page for results!

Download a factsheet on the Virginia Tech team’s findings on how well seed impact mills kill weed seeds.

This work is funded by the USDA NRCS On-Farm CIG program, the USDA ARS Areawide program, and the USDA NIFA. De Bruin Engineering provided the equipment for testing.

See more from GROW on harvest weed seed control research here.

Article by Eli Russell, Virginia Tech; header photo by Claudio Rubione, GROW

Citations

Russell EC, Flessner ML. Evaluating Weed Seed Kill Efficacy and Horsepower Draw of Two Impact Mills for Use in Soybean Production. Weed Science. Published online 2025:1-19. doi:10.1017/wsc.2025.14

Russell EC, Flessner ML. Evaluating Two Impact Mills Seed Kill Efficacy and Horsepower Draw for Use in U.S. Wheat Production. Weed Science. Published online 2025:1-18. doi:10.1017/wsc.2025.15

San Martín, C., Thorne, M., Gourlie, J., Lyon, D., & Barroso, J. (2021). Seed retention of grass weeds at wheat harvest in the Pacific Northwest. Weed Science, 69(2), 238-246. doi:10.1017/wsc.2020.91

Schreier, H. E., Vaughn, J. E., Bradley, K. W., Young, B. G., Norsworthy, J. K., Jha, P., Legleiter, T., & Johnson, B. (2023). Weed Seed Fate at Corn Harvest. Proceedings of the Weed Science Society of America Annual Meeting Vol 63 (pp. 60).

Schwartz-Lazaro, L., Shergill, L., Evans, J., Bagavathiannan, M., Beam, S., Bish, M., . . . Mirsky, S. (2021). Seed-shattering phenology at soybean harvest of economically important weeds in multiple regions of the United States. Part 1: Broadleaf species. Weed Science, 69(1), 95-103. doi:10.1017/wsc.2020.80

Schwartz-Lazaro, L., Shergill, L., Evans, J., Bagavathiannan, M., Beam, S., Bish, M., . . . Mirsky, S. (2021). Seed-shattering phenology at soybean harvest of economically important weeds in multiple regions of the United States. Part 2: Grass species. Weed Science, 69(1), 104-110. doi:10.1017/wsc.2020.79

Winans, T., Massey, R., Schreier, H., Bish, M., & Bradley, K. (2023). Harvest weed seed control in soybean with an impact mill. Weed Technology, 37(2), 113-122. doi:10.1017/wet.2023.20