Harvest weed seed control is a growing area of interest and study for farmers and researchers looking to target weed seeds during harvest. My team at Texas A&M is evaluating the weed-seed-killing capabilities of a new harvest weed seed control tool that uses blue light and heat, known as the Directed Energy Unit.

The Directed Energy Unit is the brainchild of Jon Jackson, president of Global Neighbor, Inc., who tried many different light colors and wavelength combinations to kill weeds and weed seeds. He has concluded that blue light combined with a heating mid-range infrared (IR) wavelength can do something never recorded in previous scientific literature: kill weed seeds. The next question he addressed was how to implement this technology in a farmer’s field, and one option that emerged was harvest weed seed control.

Harvest Weed Seed Control

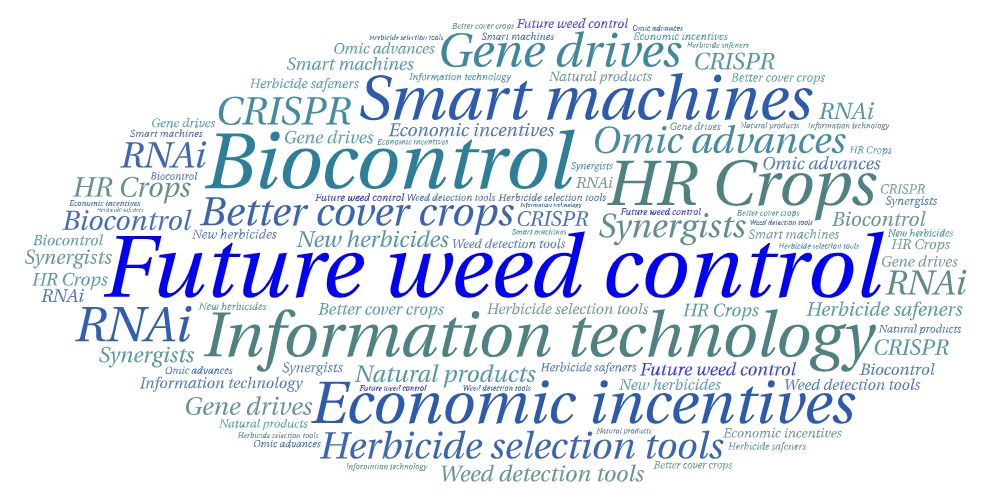

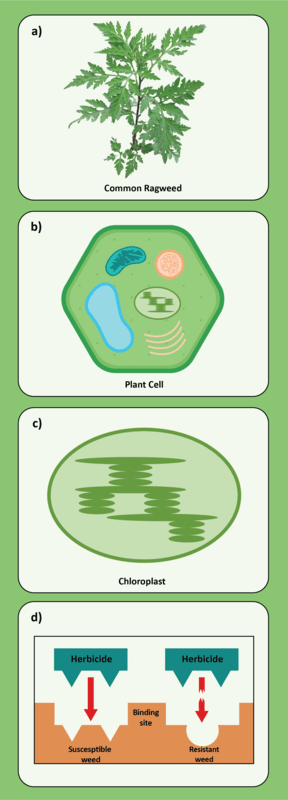

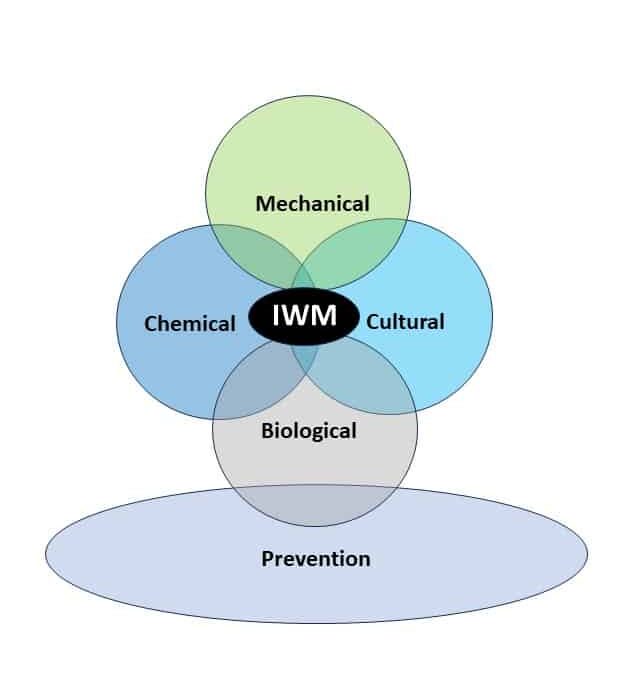

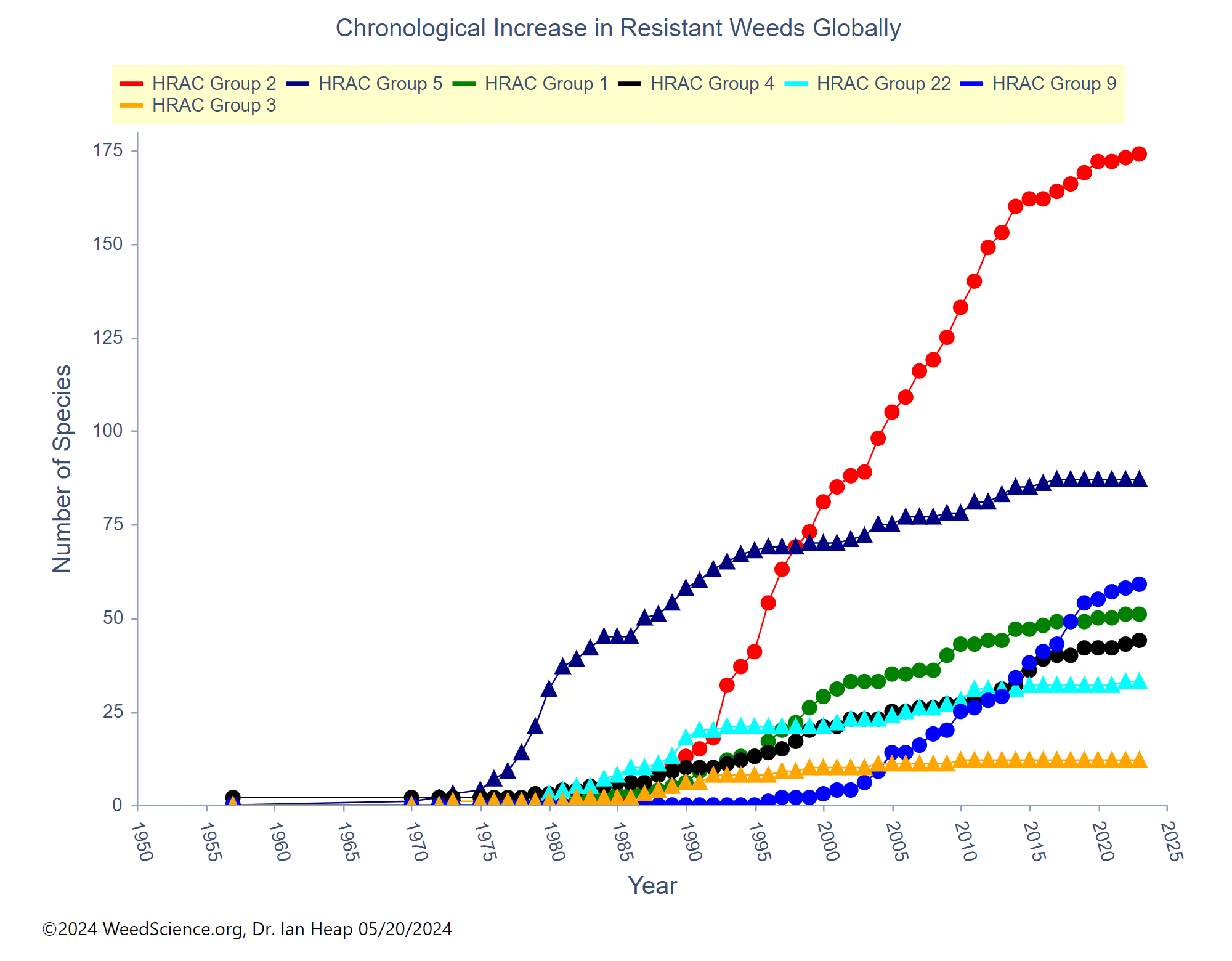

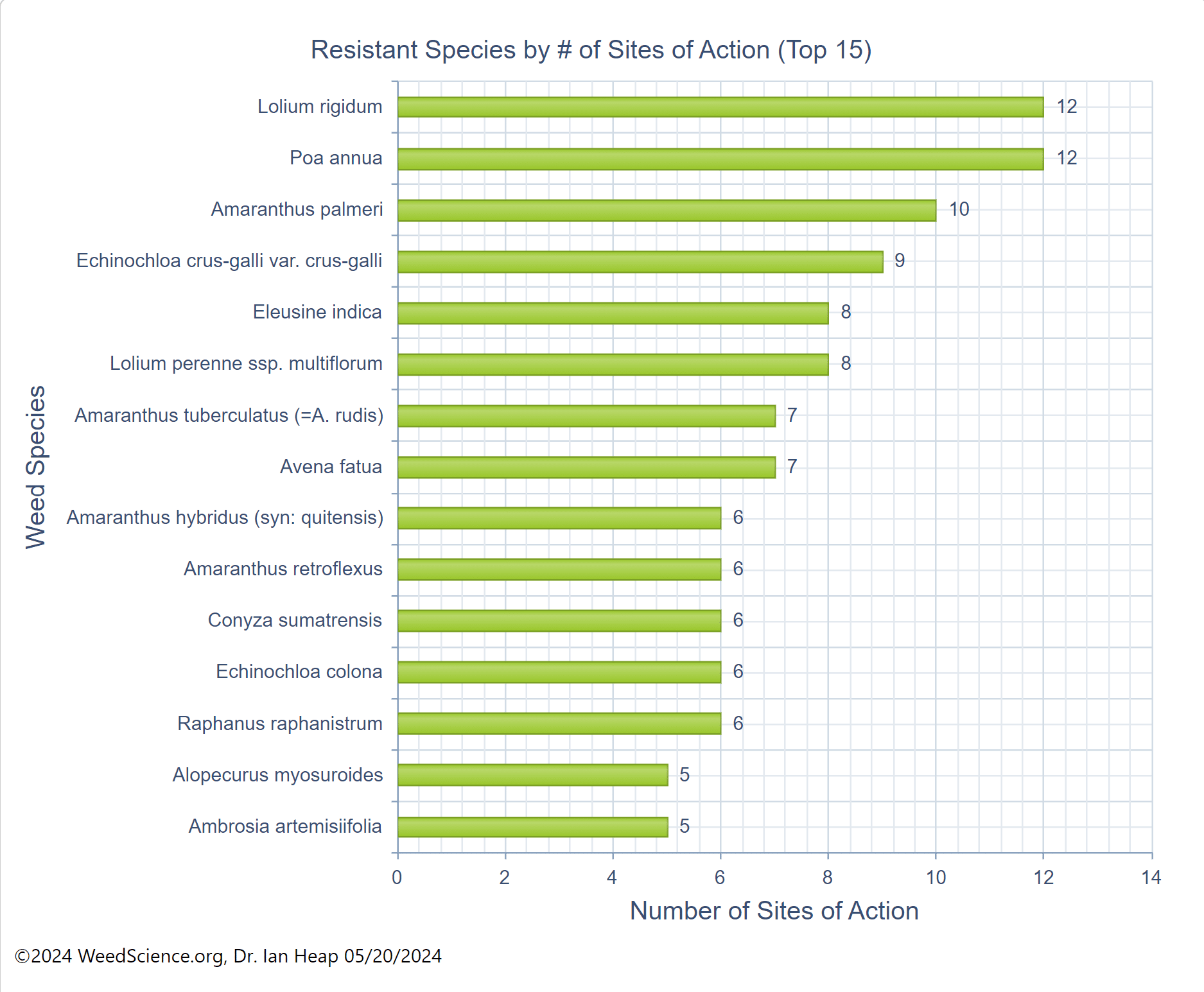

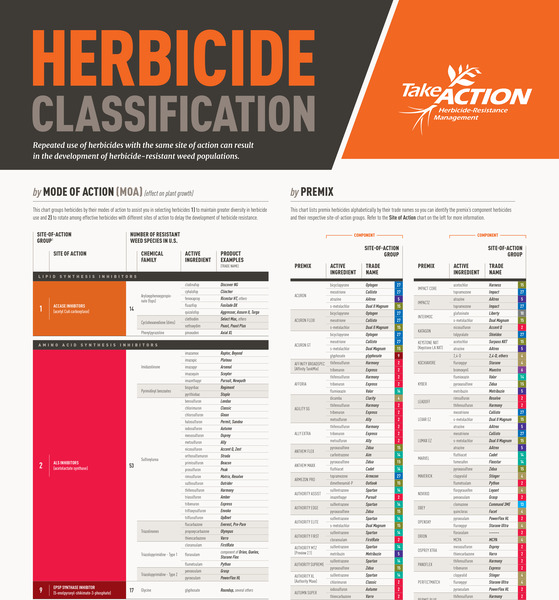

In a normal harvesting operation, the weed seed is separated from the crop in the combine through sieves and then ejected out on the field along with other plant material, known as trash or chaff. In this way, combines often spread weed seeds. Harvest weed seed control disrupts this process by capturing, directing or destroying the weed seeds and preventing them from entering the soil seedbank in a viable form. This is a widely used form of weed control in Australia, where annual ryegrass developed multiple herbicide-resistance traits rapidly and forced farmers to consider other ways to manage these weeds in a more economically and environmentally sustainable way.

There are currently five different types of harvest weed seed control that have been commercially developed. Chaff carts and bale direct systems remove the chaff or all plant residues along with the weed seeds from the field. In narrow windrow burning, all the residues (along with weed seeds) from the harvest are concentrated in a single line, which is then set on fire to kill the weed seeds. Chaff lining and tramlining place chaff in a row behind the combine, so all the weed seeds are in one place, where they are easier to manage. Seed impact mills are the most recent form of harvest weed seed control, invented by an Australian farmer, Ray Harrington, in 2005. These are mills with rotary blades that destroy the weed seeds in the chaff, making them non-viable.

A Potential New Method of Harvest Weed Seed Control

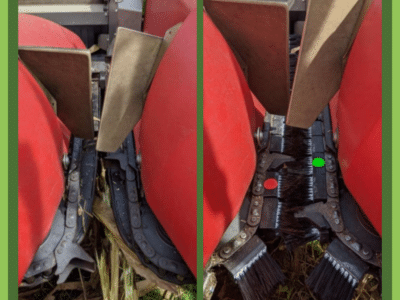

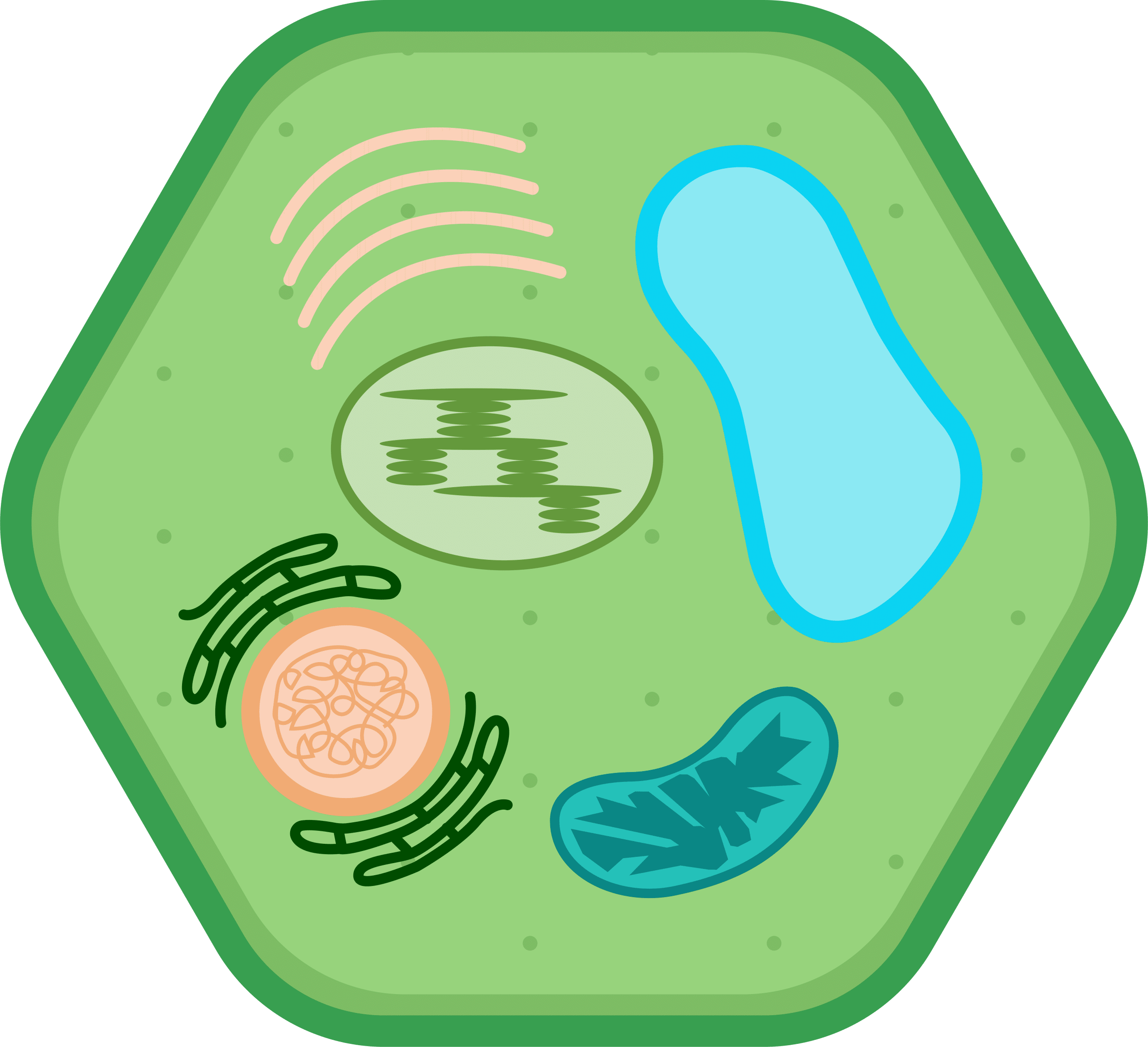

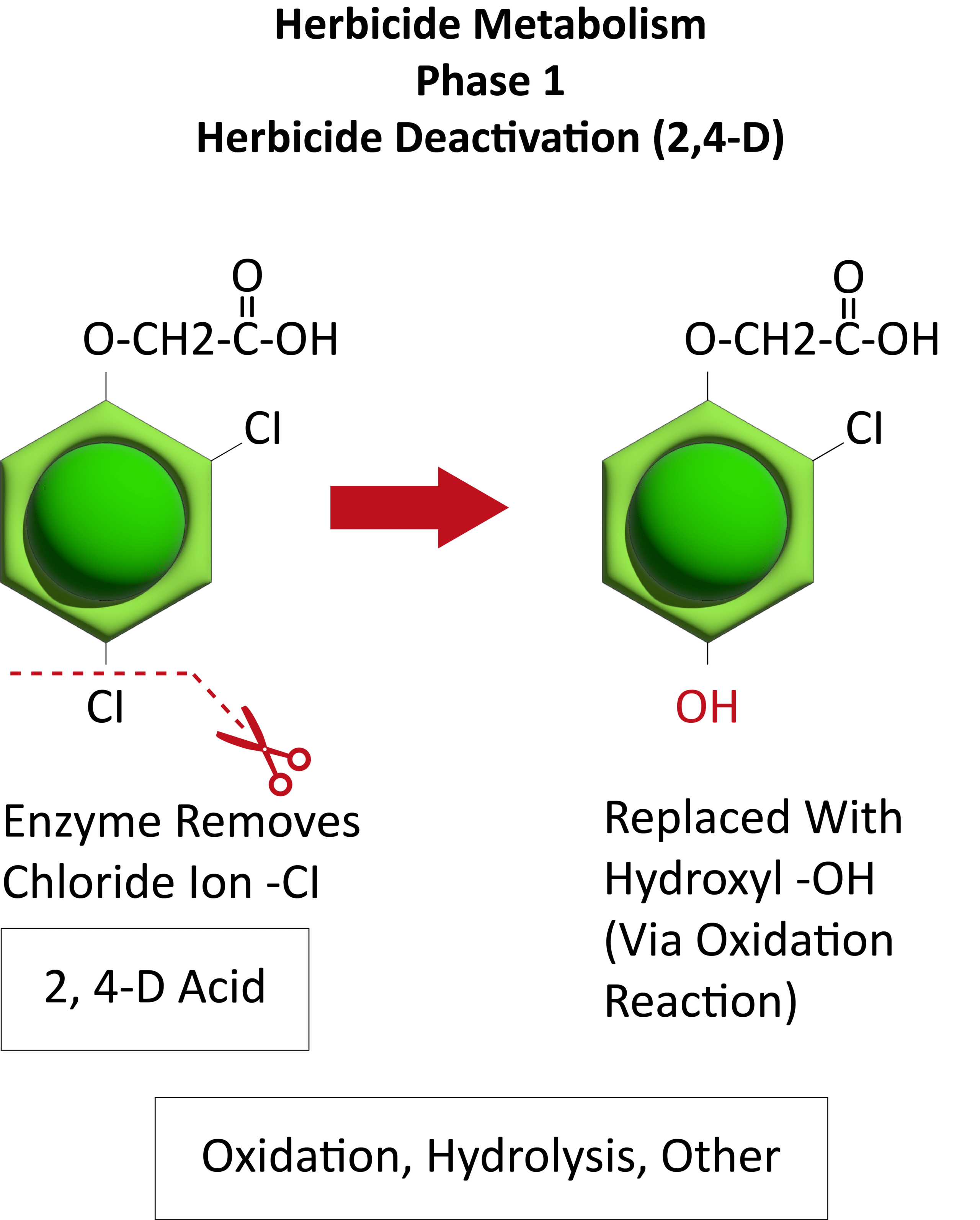

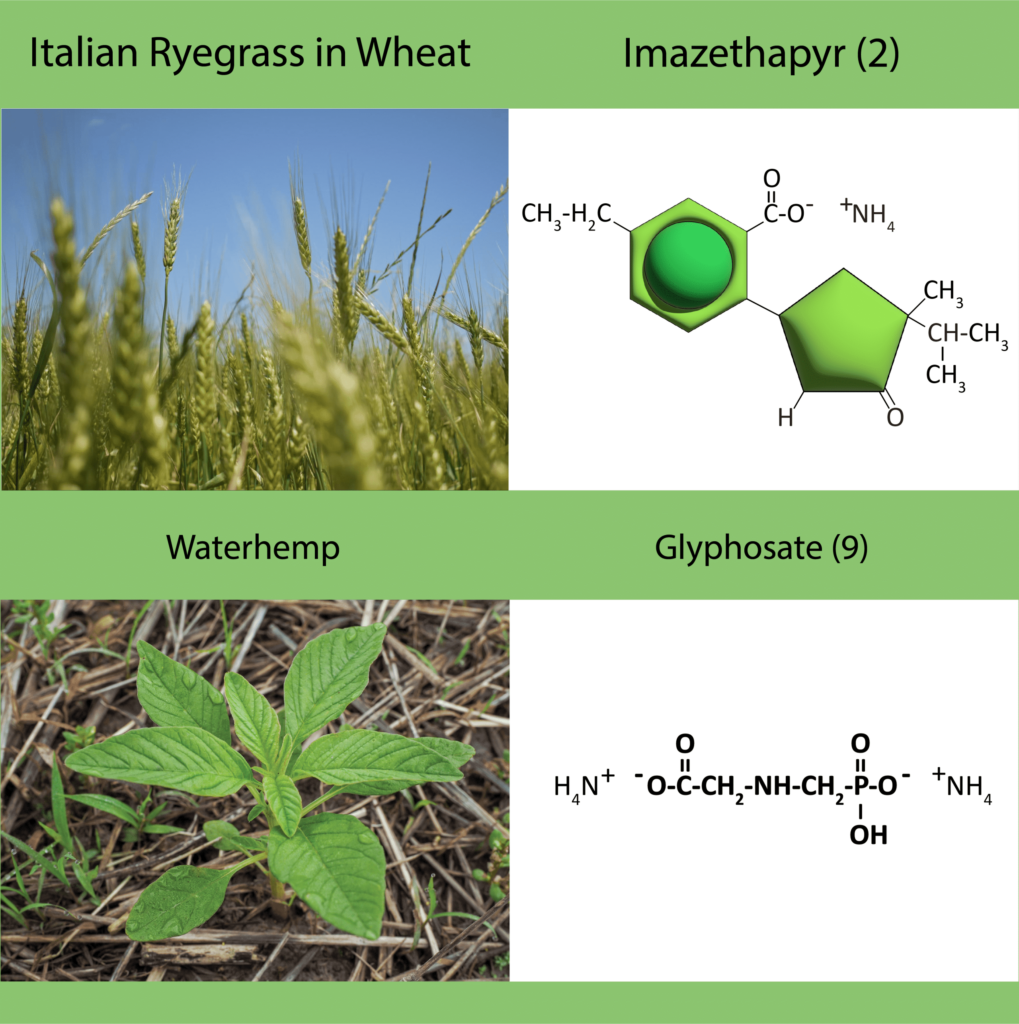

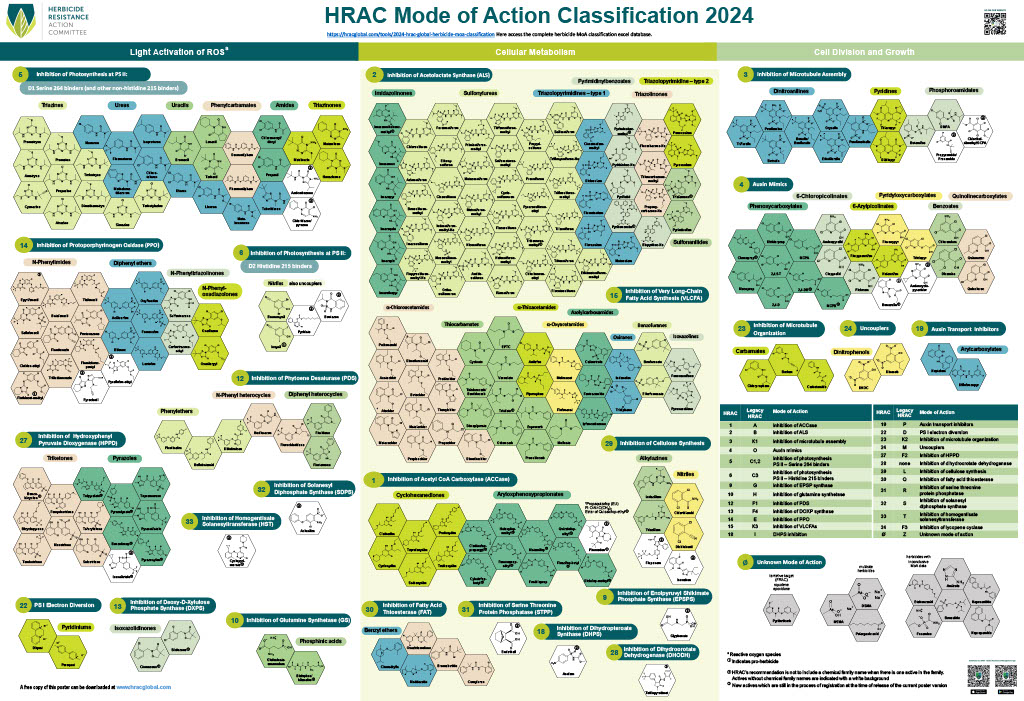

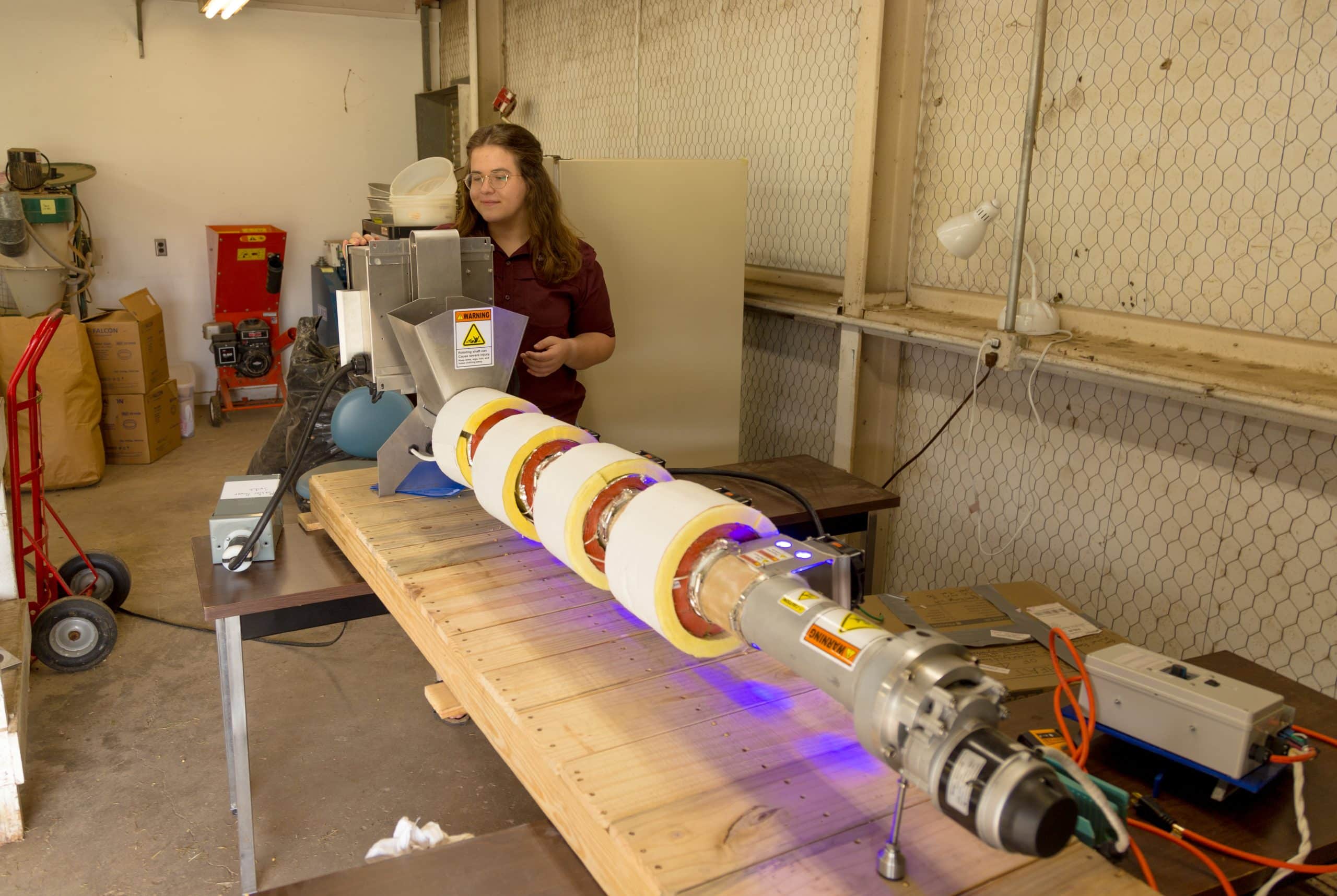

Now Global Neighbor has developed a potential new method of harvest weed seed control, known as “directed energy,” which combines blue light and mid-wave infrared radiation. A machine generating the blue light and mid-IR wavelengths (i.e. directed energy) is attached to a combine and can act as a heating agent to kill weed seeds (Figure 1). There is limited research and mixed results on plant species’ response to blue light and even less information on possible response of seeds to blue light. Researchers have previously looked at heat as a way to kill weed seeds, but the temperatures needed to kill the seeds were often very high and species-dependent. For example, Palmer amaranth needed to be exposed to 400 C (752 F) for 60 seconds to achieve complete seed kill (Norsworthy et al. 2020).

Currently, the Directed Energy benchtop unit has a chute, which funnels the weed seeds and chaff into an auger, which rotates the chaff-seed mixture through a cycle of blue light and mid-IR radiation four times before exiting the machine.

Does Blue Light and Heat Kill Weed Seeds?

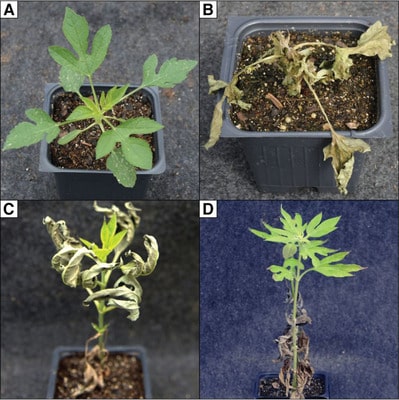

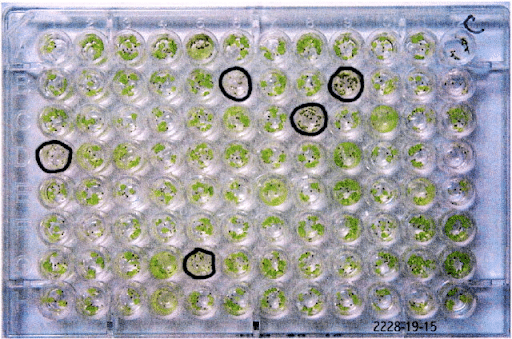

To test the Directed Energy Unit’s ability to kill weed seeds, my Texas A&M research team tested four different species: hemp sesbania, common morningglory, green foxtail, and Palmer amaranth. The weed seeds were mixed with chaff from a wheat crop during the stationary testing. We tried to kill the weed seeds by varying both the intensity of mid-infrared radiation and the duration of blue light exposure, to determine the parameters that provided the best seed kill.

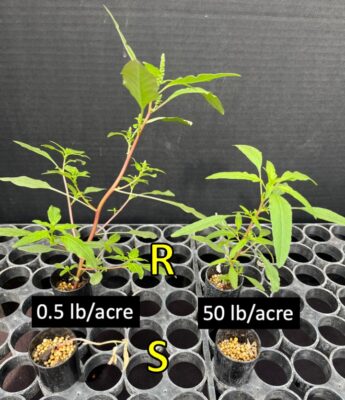

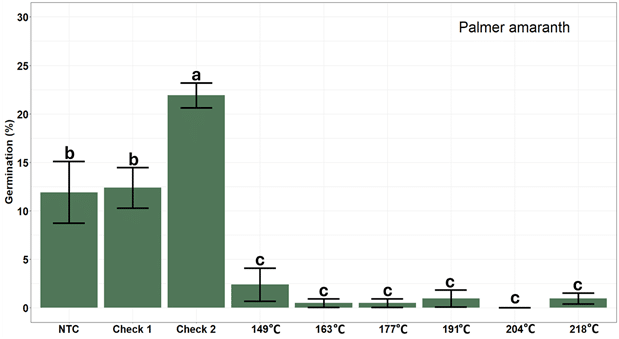

We found that the optimal temperature of the heating unit with blue light required to decrease seed germination varied among the weed species. Palmer amaranth germination decreased by 83% at 149 C (300 F) when compared to the non-treated control (Figure 2). The lack of seed germination after the directed energy treatment suggests that they either died or are in a dormant state.

These are promising initial results, but to better understand the weed seed response to blue light and mid-IR radiation, we need to understand the contribution of each factor and their combined effects on weed seed germination. The Directed Energy Unit is continually being improved upon, with multiple researchers studying the weed-seed kill rate for problematic weed species in their area and working to understand the physiological mechanism that contributes to seed death.

Future research will need to look at the integration of the Directed Energy Unit on a combine and the effectiveness of the technology based on different crop chaff types and moisture levels.

Article by Sarah Chu, Texas A&M University