Why make two passes across a field when one will do? That’s the logic that has motivated Virginia farmer John Shepherd to run his New Holland T8020 tractor with both a roller-crimper on the front and a Kinze 3600 planter attached to the back.

The set-up allows Shepherd, who farms about 3,000 acres of crops in south-central Virginia, to roll down standing cover crops and plant his cash crop into the residue, at the same time.

The system has worked so well with weed suppression, it’s allowed him to replace entire herbicide passes in some years.

“On some of my corn acres this year where I crimped rye cover crops, I didn’t have to spray a postemergence herbicide at all,” he says.

Shepherd invited GROW researchers to visit his operation, Shepherd Grain Farms, near Blackstone, Virginia on August 17, to see how the set-up works.

HOW IT WORKS

Shepherd aims to terminate his cover crops with a herbicide application as close to the spring crop’s planting date as possible – usually no more than one or two days ahead, so he often “plants green” into the cover. Ideally, he says, the sprayer will run ahead of the crimper-planter by 50 to 100 acres, terminating the cover and applying soil residual herbicides while the cover is still standing, which gives the chemicals a better chance of penetrating to the soil.

If he misses that narrow window after spraying, Shepherd has to wait longer to plant, until the rye is totally desiccated.

“I either want to crimp while it’s still all the way green or all the way dead, one of the two,” he explains. “The worst thing you can do is have half-dead rye, because then it behaves like baling twine – it wraps up everything on your planter.”

With row cleaners running, his Kinze planter parts the freshly crimped rye easily and seed placement and row closure haven’t been a problem, he adds.

His favorite cover crop for this system is cereal rye, which he plants before both soybean and corn crops.

To avoid his decaying rye crop tying up nitrogen at critical development periods for the corn stand, he adds 40 to 45 units of liquid nitrogen in bands at planting. “The rye can’t lock that up,” he notes. “If you broadcast nitrogen, it might, though. That’s why you have to get that N banded into the soil.”

Each year varies, but in the unusually dry conditions of summer 2022, Shepherd credits the thick mat of dead rye with helping him eke a decent corn crop out of a marginal production year.

The leftover rye residue not only suppressed weeds and replaced a postemergence herbicide application, but it kept moisture sequestered in the soils of his cornfields longer into the summer. “When you get an inch of mulch on top of the ground, it really conserves moisture,” he explains. “And when it rains, it also slows down the water, so the field can absorb it much better.”

THE HURDLES

Shepherd is quick to note the challenges of his dual crimping-and-planting system. His roller-crimper, purchased through Harrell Ag Products in Georgia, is extremely heavy. It’s a big load even for his 280-horsepower tractor, and requires fresh, good tires to run.

“You’ve got to have a hell of a tractor to pick this thing up,” as Shepherd puts it. “The autosteer does not work when you have this roller-crimper on the front and the planter on the back,” he adds. “I just try to follow the lines.”

Turning can also be a challenge, and requires picking up the roller-crimper a little to slide over the rye as the tractor pivots.

Compaction is also a concern. Shepherd tries to abide by a concept called “controlled traffic farming,” where operators work to keep the wheels of all field equipment – planters, sprayers, and combines – running in the same tracks, to limit the area of compaction. (See more on this concept from the Natural Resources Conservation Service here: https://www.nrcs.usda.gov/resources/guides-and-instructions/controlled-traffic-farming-ac-334-conservation-practice-standard).

For growers who might be intimidated by these challenges, Shepherd notes that a two-pass system, with the tractor pulling the planter and the roller-crimper separately, works well, too. It’s easier on the tractor, and the autosteer will work just fine.

But it also requires careful attention to planting in the same direction of the roller-crimper, shortly after the field has been flattened. “If you’re going to run it on two different passes, your autosteer had better be perfect, because if you even get one row going against the grain, the crimped rye will wrap up the whole works,” Shepherd cautions.

“I just prefer to do it all at one time,” he concludes.

See more information from GROW on using cover crops for weed control here: https://growiwm.org/cover-crops/.

PRECISION SPRAYING PRESERVES HERBICIDES

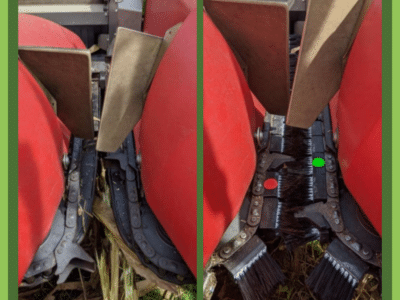

Shepherd uses a pulse-width modulation system on his Case IH 3240 sprayer, called PinPoint, from CapstanAG, which allows for a more precise spray application.

Each nozzle has a device called a solenoid attached to it. The solenoid turns the nozzle on and off, based on the tractor’s speed and the turning radius of the sprayer boom, which ensures an even spray coverage pattern.

“So if you’re only going a tenth of your normal speed, for example, the nozzles will only be on for a tenth of the time,” as Virginia Tech Extension weed scientist Michael Flessner explains.

And as the spray boom turns at the end of the row, the solenoids limit the nozzles’ output on the inside of the curve, while leaving the nozzles on the outside of the turn completely open. “So if you’re going around a turn, it can actually spray the correct gallons per acre (GPA) along the length of the spray boom, on both the inside and outside of the turn,” Flessner says.

When it works correctly, the system limits spray overlap within a field, which conserves herbicide use. When navigating the small-acre, oddly-shaped fields of southern Virginia with his sprayer, Shepherd estimates it saves him at least $100 worth of chemicals per tank. The more even spray coverage should also improve weed control, and by maintaining an exact GPA and spray pressure, regardless of the tractor’s speed, Shepherd believes it limits spray drift, as well.

“For the amount of chemical you’re saving, it’s a no-brainer for me,” he says.

Follow GROW news at https://growiwm.org