This article is reprinted with permission from Iowa State University Extension and Outreach

Key Points

- Precision spray technology is available in the ag marketplace to provide selective post-emergence herbicide applications.

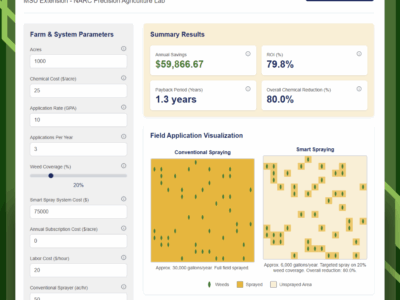

- Iowa State University conducted a field scale demonstration of a commercial precision spray system on five conventionally managed soybean fields totaling 415 acres.

- Herbicide savings per field was 90.6%, 87.6%, 87.2%, 71.2%, and 43.9% respectively. Herbicide savings were directly influenced by the initial weed pressure in the field.

- Average product savings across all fields was 76% and had an economic savings of nearly $6,500 ($15.7/ac) from reduced herbicide use.

Precision Spraying Technology

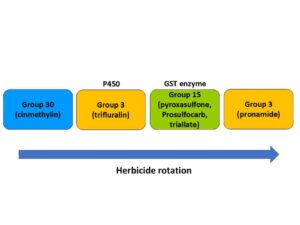

Several environmental and soil properties impact the effectiveness of pre-emergence herbicide programs. In addition, chemical characteristics and combinations of herbicide products also influence weed control performance. These properties, coupled with the frequent and high precipitation across most of Iowa in the spring of 2024, may have caused a breakdown in early season herbicide programs. Early breakdown of pre-emergence herbicides generally leads to a higher weed presence during the growing season.

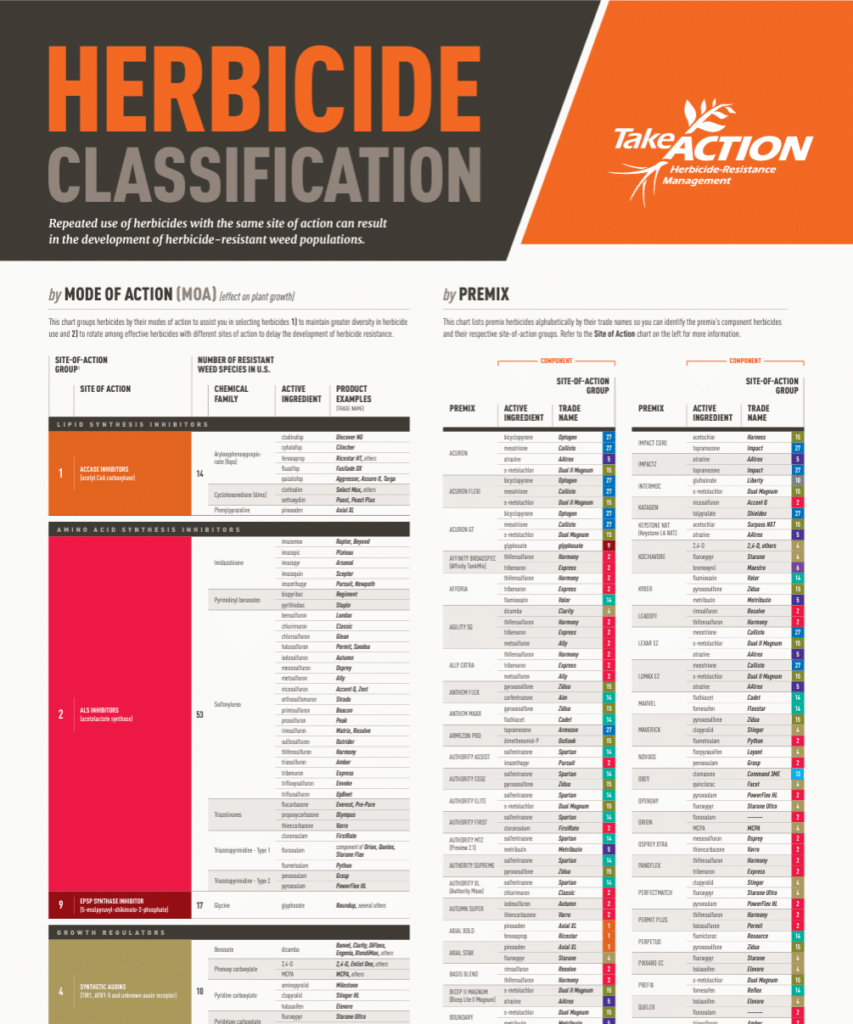

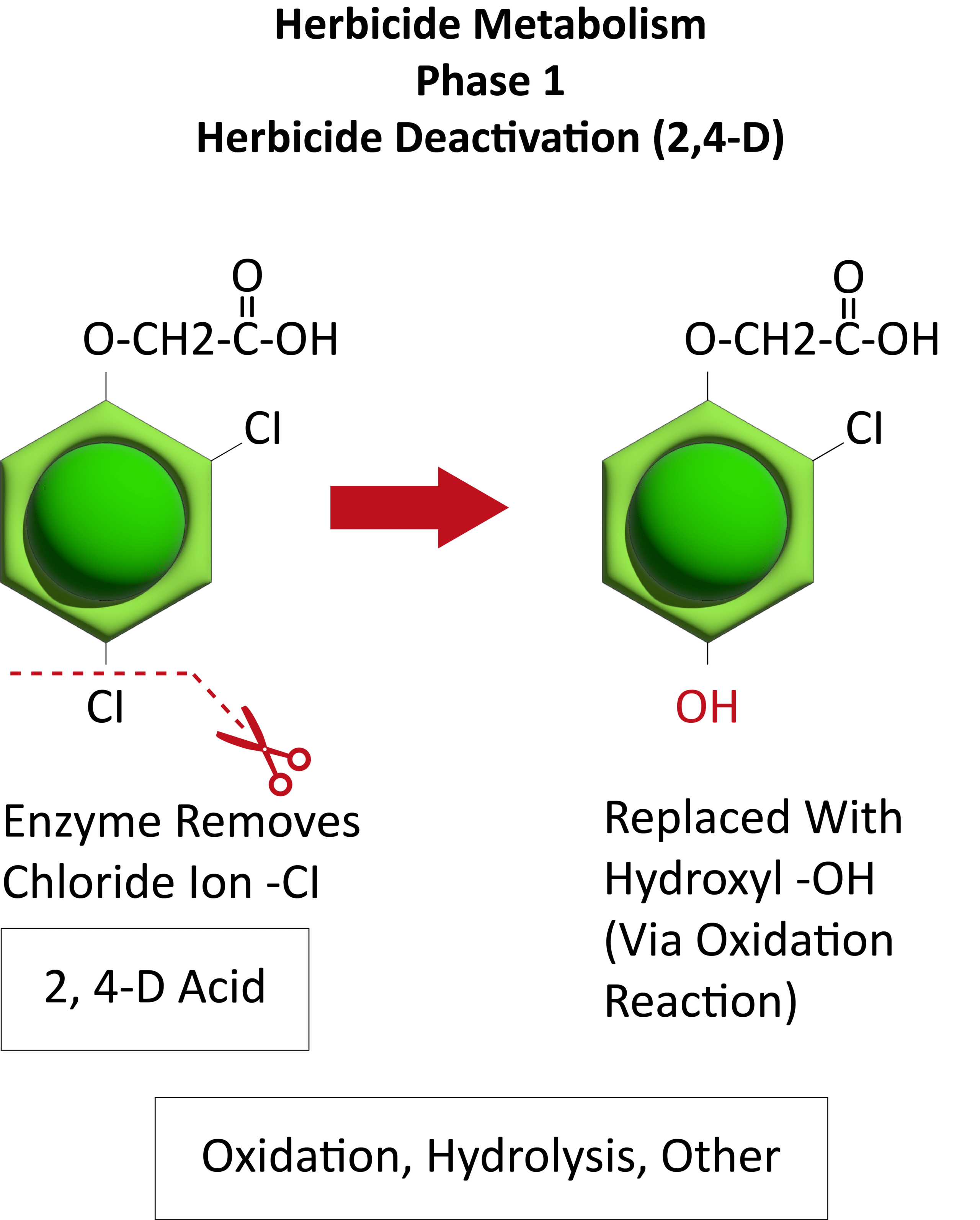

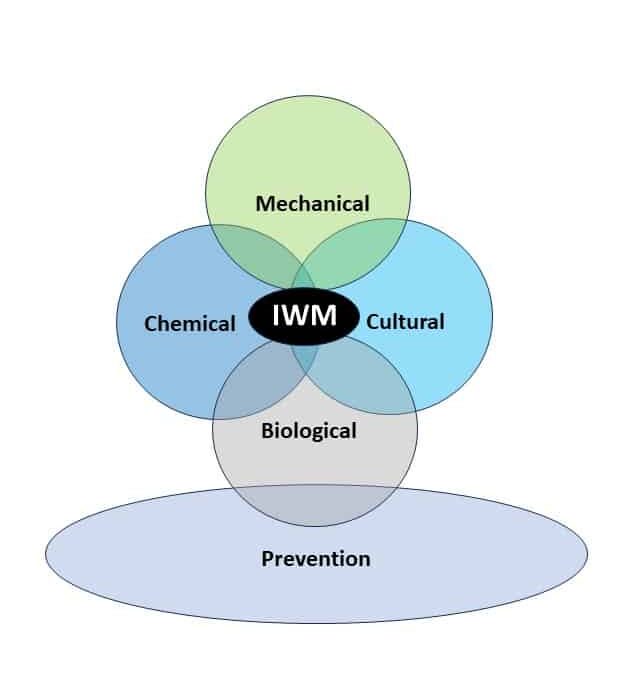

Historically, corn and soybean growers manage these weeds through timely post-emergence herbicide applications when field conditions permit. To date, these post-emergence herbicide applications have been broadcast applications across the entire field, which have proven to be successful but can come with a high chemical cost. Newly developed precision spraying technology allows applicators to precisely spray only the emerged weeds while reducing the total volume of herbicides applied and the associated chemical costs.

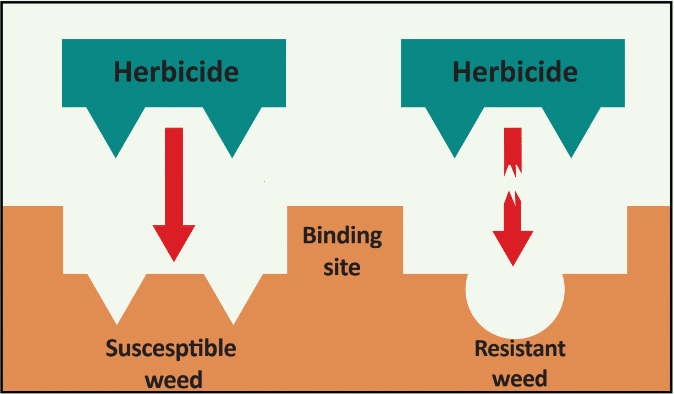

Several companies, including the joint venture of BASF and Bosch (https://www.onesmartspray.com/), John Deere (https://www.deere.com/en/sprayers/see-spray/), and Greeneye Technology (https://greeneye.ag/), have brought precision spraying technologies to market. These technologies allow the shift from a broadcast or blanket application to a precise and selective application. This allows chemistry to be applied only where it’s needed and avoid wasteful herbicide application in unneeded areas.

These sprayers are equipped with camera systems that have diverse capabilities. Entry-level systems provide “green vs. brown” capabilities, which will detect weeds (green) in fallow fields (brown soil or residue). In Iowa this technology would be applicable to pre-emergence spraying of contact herbicides in no-till or strip-till management practices. More advanced systems provide “green vs. green” capabilities, which will differentiate weeds from the surrounding desirable crop and only spray the weeds. In either situation, weeds are detected in real-time and immediately sprayed.

Trade names for these precision spraying technologies vary, but generally terms like “See and Spray™”, “Selective Spray”, or “Smart Spray” are used to describe this new class of precision spray equipment. In addition to including cameras along the boom for detecting individual weeds, additional technologies or changes to current spray practices are required to implement these precision spraying systems including:

- Boom Height Control: Precision spray technology requires consistent boom height control to keep the cameras and boom at a stable height above the ground.

- Vehicle Speed: Precision spray technologies generally have a vehicle speed limitation between 10–15 mph, depending on the manufacturer. The maximum speed has been increasing over time as manufacturers continue to improve the precision spray technologies, but today it remains below the maximum application speed for broadcast application.

- Individual Nozzle Control: Precision spray technologies generally require individual nozzle control. Cameras mounted along the boom will command individual or groups of nozzles to turn on to apply herbicide to the target weeds.

- Compatible Nozzles: Specific nozzles are required to support precision spraying application based on manufacturer and herbicide product requirements.

- Boom Recirculation: With the significant variability in the number of individual nozzles that are on at any point in time, boom recirculation is recommended to help maintain consistent herbicide coverage during precision spray applications.

Herbicide Savings

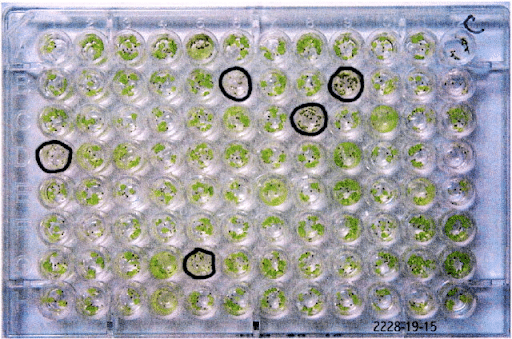

Iowa State University recently completed a field scale demonstration of precision spray technology on five conventional tilled soybean fields that totaled 415 acres using a John Deere See and Spray™ Ultimate (https://www.deere.com/en/sprayers/see-spray/) machine. Weed pressure before planting was variable based on the field and prior management practices. All fields were located within Boone and Story counties and received similar pre-emergence residual herbicide programs as part of their spring crop management plan.

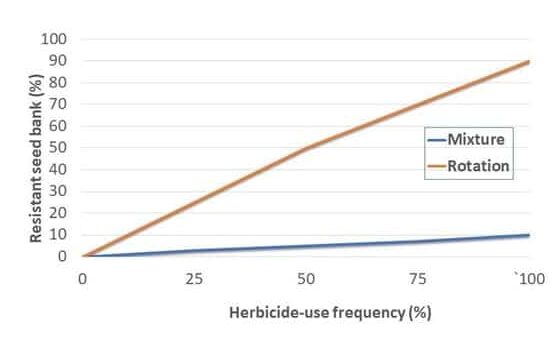

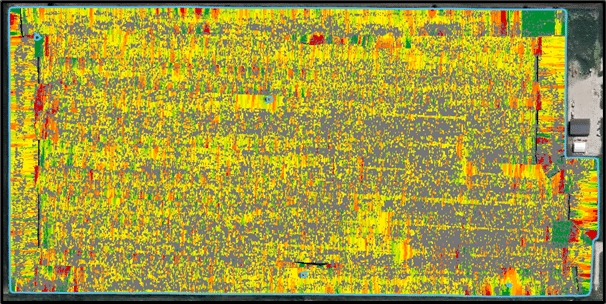

Three of the five fields showed strong pre-emergence residual herbicide performance despite the high rainfall during the 2024 spring growing season and had the least amount of initial weed pressure. Fields 1, 4 and 5 subsequently had 87.2%, 90.6%, and 87.6% total savings in the post-emergence herbicide pass, respectively. The average savings was 88.4% across these three fields and economically saved $4,300 ($18.1/ac) in chemical costs alone.

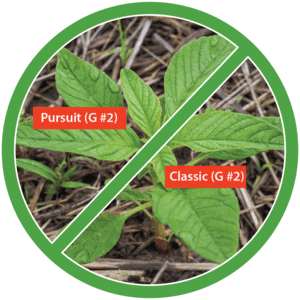

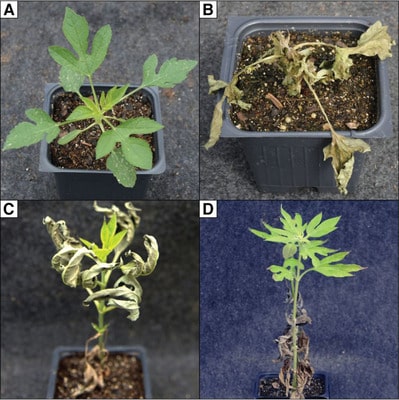

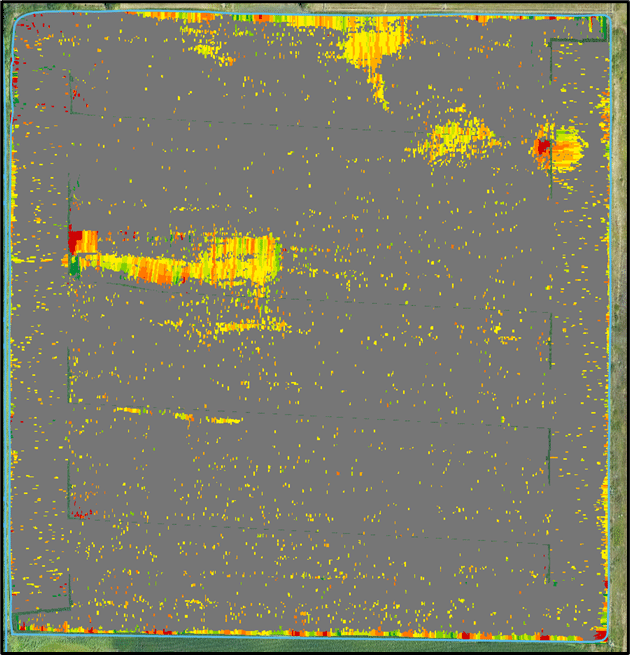

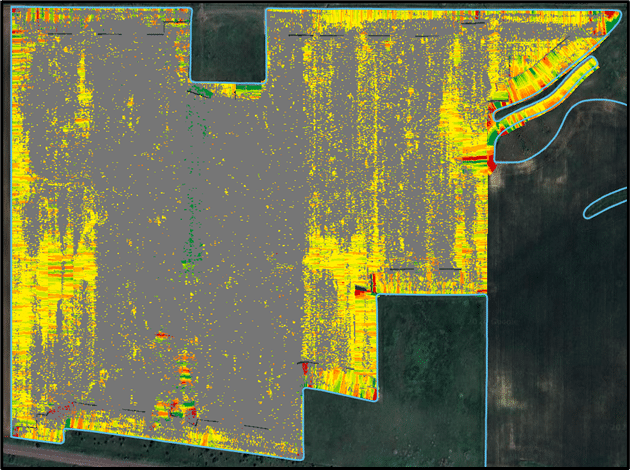

Field three had variable weed pressure due to past management practices which split the field with herbicide-resistant and conventional soybean varieties. This resulted in the center section of the field, where past herbicide-resistant crop varieties had been planted, having significantly more reduction in herbicide use than other parts of the field with greater underlying weed pressure. The total herbicide savings across the entire field was 71.2%. In addition to the reduction in herbicide volume applied, the as-applied map of current weed density provides a useful tool in planning weed management practices in the future. The as-applied data highlights that expectations for total herbicide savings are a function of the technology and the underlying weed pressure. Specific herbicide reduction levels are not guaranteed and increased savings will generally be associated with fields that have less weed pressure at the time of spraying. Years with strong residual herbicide control and more normal rainfall patterns will offer greater herbicide savings potential.

Field two produced the lowest herbicide savings in the trial with a total savings of 43.9%. This field was tilled on April 13th, planted on April 15 and received significant rainfall throughout the spring, which resulted in poor residual herbicide control. Field scouting prior to planting documented significant in-season weed pressure that would normally warrant a full broadcast application.

In summary, even with an anticipated weed pressure higher than normal due to excessive spring rainfall near Ames in 2024, results showed an average field area savings of 76% with the range being 43.9% to 90.6%, resulting in significant herbicide cost savings. Drone imagery on the day of application and post application scouting images confirmed both the existence of variable weed pressure and the effectiveness of the precision spray technology to correctly identify and apply herbicide to emerged weeds.

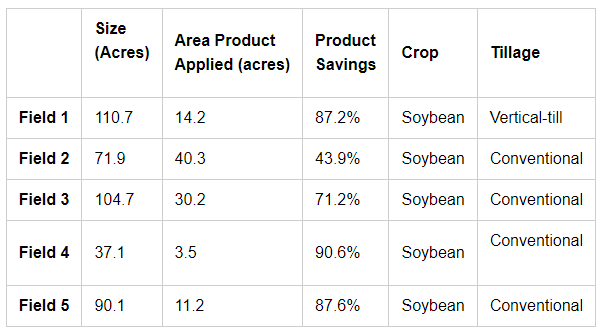

Below is a summary of the fields tested with this precision spray application technology. A wide range of field sizes were evaluated with the smallest and largest being 37.1 and 110.7 acres, respectfully. All fields leveraged conventional or vertical tillage practices.

In conclusion, effective weed management using precision spray technology was demonstrated at field scale and had an average product savings of 76%. Initial weed pressure determined individual field savings with the highest precision spraying technology performance when weed pressures were low at the time of the second herbicide application. Overall, 4,700 gallons of tank mix and $6,500 worth of herbicide product were saved across the 415 acres using the John Deere See and Spray™ Ultimate machine while maintaining clean fields through canopy formation.

See this article as it was originally published in ISU’s Integrated Crop Management News page.

Authors

Doug Houser, ISU

Matt Darr, ISU

Ryan Huffman, ISU

All images courtesy Iowa State University