Listen to this article above!

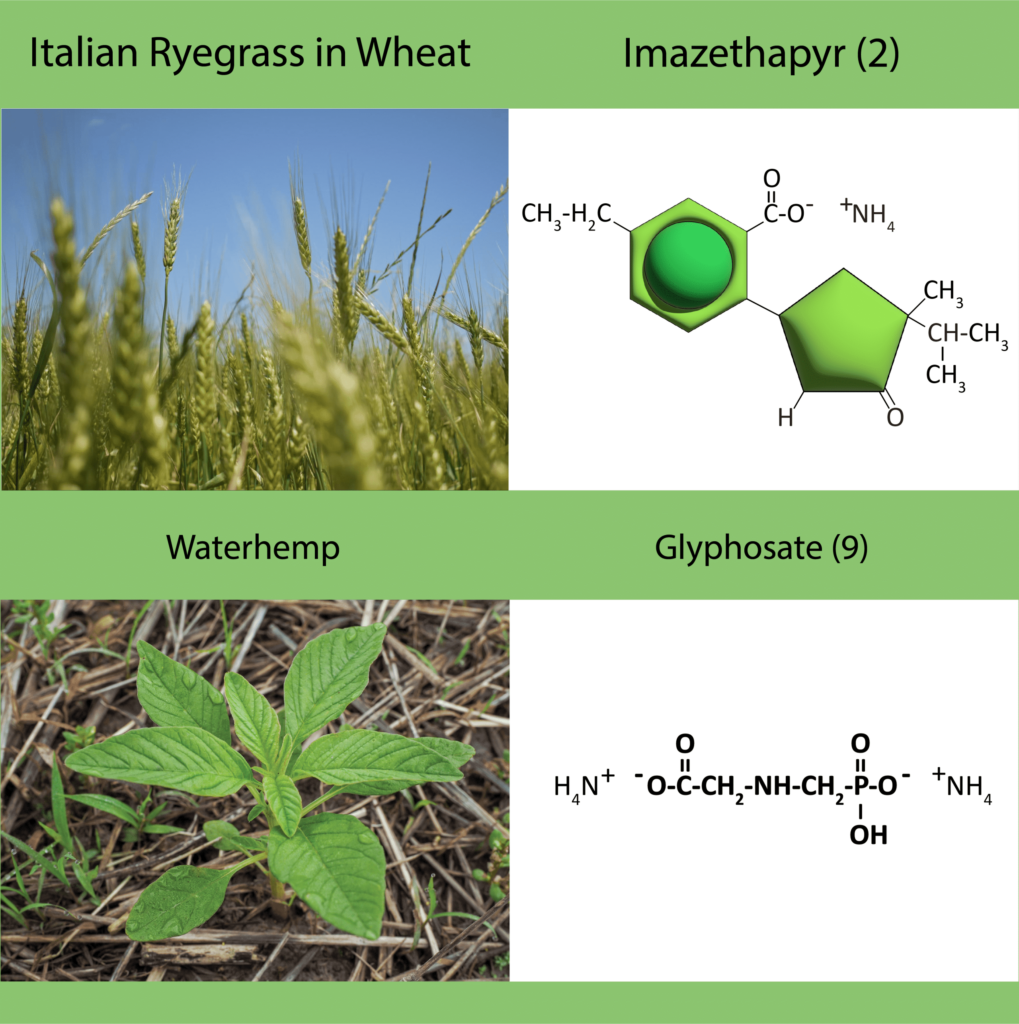

Who said that electrocution is just for weeds? “If these electrical weeders can do a good job of killing weeds, why can’t they do a good job of killing cover crops?” asks Ryan Hamberg, a Texas A&M weed science graduate student under the advisement of Dr. Muthu Bagavathiannan. Hamberg and Oregon State researchers Dr. Aaron Becerra-Alvarez and Dr. Marcelo Moretti are independently examining electrocution as a method of cover crop termination. Their findings could expand farmers’ options when it comes to managing cover crops on their farming operations.

The preliminary findings from each university show that the shock factor is powerful. One pass of the Zasso EH30 or EH60 at roughly 0.5 miles per hour effectively terminated oats, crimson clover, winter peas and brown mustards. In Texas, species like cereal rye and hairy vetch were more difficult to terminate, requiring four passes for 90% termination. Many questions remain unanswered, but both groups of researchers pinpointed plant moisture and weather factors as critical to electrocution’s cover crop termination efficacy.

The researchers also emphasize that they’ve only completed one year of research, and there are many more variables to explore before definitive conclusions are drawn about electrocution’s viability for cover crop termination.

Takeaways from Texas to Oregon

Each researcher’s region is different, but Becerra-Alvarez and Hamberg had a few similar takeaways from the initial stages of their research.

First, both researchers note that electrocution expands the cover crop termination toolbox. “It could add flexibility for nonchemical cover crop termination,” Hamberg states. Organic no-till growers have fewer options when it comes to cover crop termination, and complete termination is critical for all growers to ensure cover crops don’t become pesky weeds in the growing season. (Read our recent article on cereal rye’s potential to become a weed here.)

Similarly, plant moisture and weather play a key role in electrocution’s efficacy and safety. Moisture is critical to the plant’s conductivity, but too much soil moisture can cause the machine to overload and potentially direct more electricity to the soil than to the cover crop. Dry plants don’t conduct electricity well and will go unaffected by electrocution, and they can also act as a fire starter.

Using Electrocution for Cover Crop Termination in the Pacific Northwest

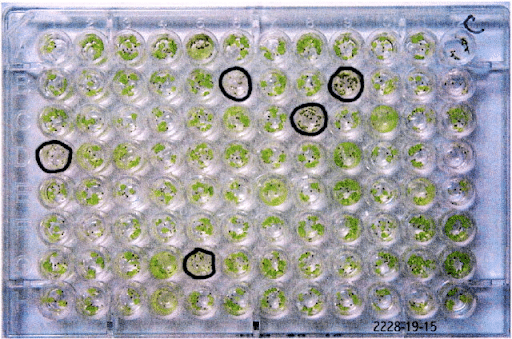

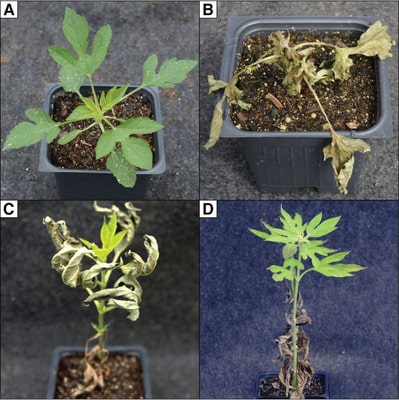

Dr. Becerra-Alvarez’s research began with an oat-crimson clover mixture (80 pounds per acre of oat to 40 pounds per acre of crimson clover). The mixture, chosen because it was available at Oregon State’s research center, proved susceptible to the Zasso EH30 when terminated as the clover began to flower.

One electrifying pass over the oats-crimson clover mix achieved 80% termination. Mowing the cover crop and then using electrocution increased that termination to over 90%. On average, this cover crop mixture reached 3,294 pounds per acre before termination.

But mowing created a fire-prone blanket of residue, and the dried biomass created a fire hazard when followed by electrocution. “We started early in the morning and were fine because there was dew,” Becerra-Alvarez explains. “But as it started to get warmer and winds picked up, we saw more dry biomass trying to catch fire.” He stressed the importance of understanding weather factors and plant moisture before using electrocution to terminate cover crops.

Using Electrocution for Cover Crop Termination in the South

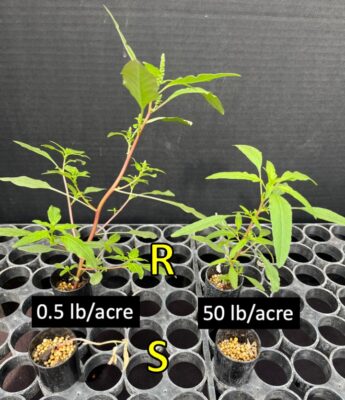

In Texas, Hamberg found one pass with the Zasso EH60 effectively terminated flowering brown mustard and winter pea monocultures. Cereal rye and hairy vetch had 90% termination after four passes, but even then, Hamberg observed that 3% to 5% of the cereal rye regrew.

Cereal rye and hairy vetch may be difficult to terminate due to cover crop moisture, root structure, and plant physicality, Hamberg theorizes.

Brassicas have one main taproot that Hamberg likens to a conductive lightning rod. Cover crops with extensive root systems could be more difficult to terminate, as parts of those systems could theoretically survive after electrocution. Similarly, plants with little moisture don’t conduct electricity as well and could pose a fire risk.

But cereal rye’s difficulty to terminate isn’t unique to electrocution. “We weren’t too discouraged because it can also take multiple passes [to terminate] with the roller crimper as well,” Hamberg explains. A different termination timing could potentially make cereal rye electrocution more efficient and prevent regrowth.

Cover crop species influenced electrocution’s effectiveness more than biomass, and Hamberg notes that brown mustard — which responded the best to electrocution — had the most biomass of the tested cover crops. He concludes that choosing the right cover crop species and termination timing is important to ensuring full cover crop termination with electrocution.

Becerra-Alvarez’s and Hamberg’s future research will focus on factors such as other cover crop species, mixtures, densities, termination timings, and Zasso operational speeds. “Electric weed control is a new technology that we’re still evaluating, but there’s good potential for it to work in different scenarios,” Becerra-Alvarez says.

Explore GROW’s website for more information on weed electrocution and cover crop management and termination.

Article by Amy Sullivan, GROW; Header and feature photo by Ryan Hamberg, Texas A&M