Harvest weed seed control is an Australian innovation born of necessity.

Farmers have long relied heavily on herbicides in the Australian cropping regions, explains Dr. Michael Walsh, a weed scientist with the University of Western Australia. There, rainfall can be scarce, fields may stretch for over 1,000 hectares apiece, and no-till is king.

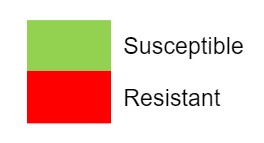

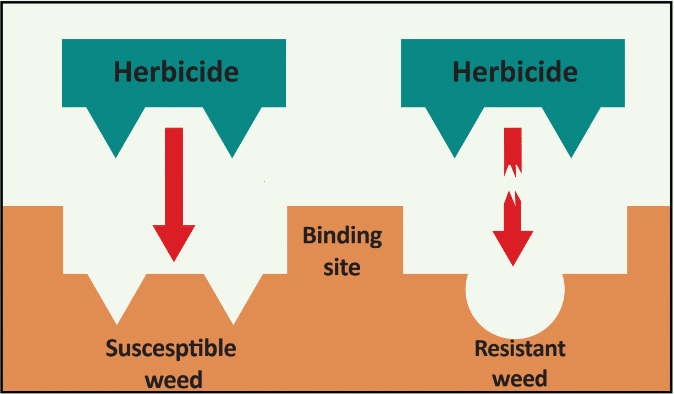

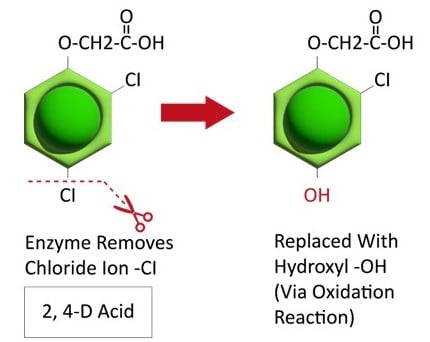

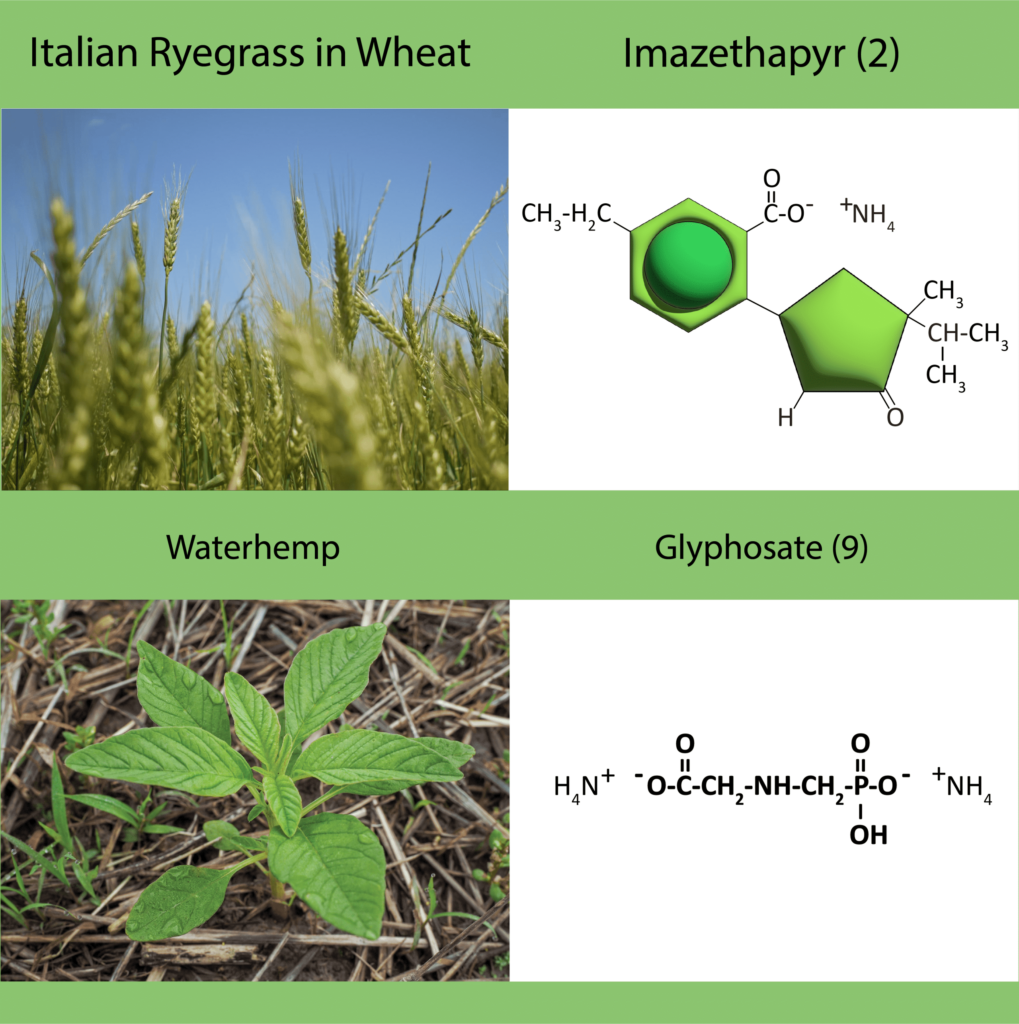

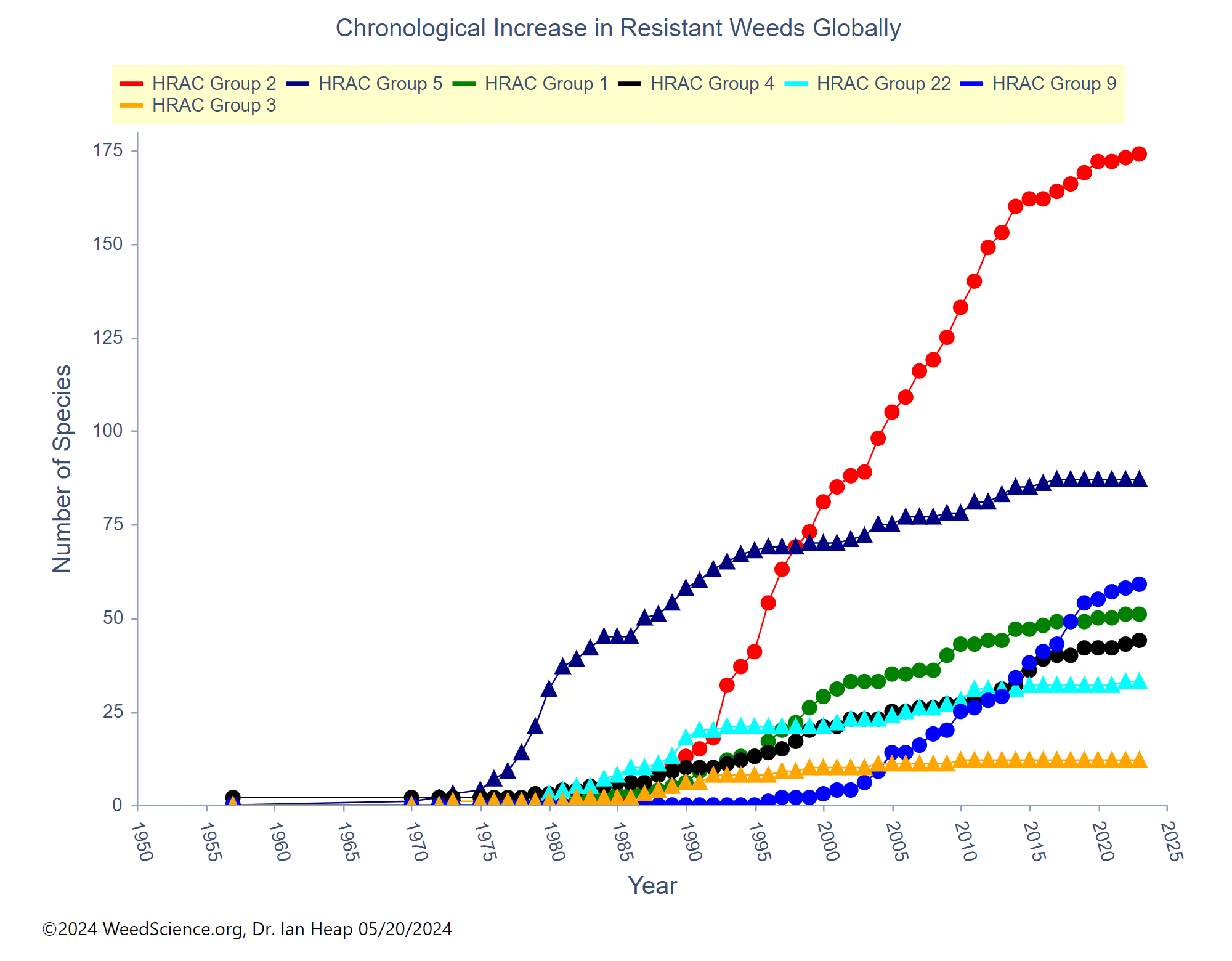

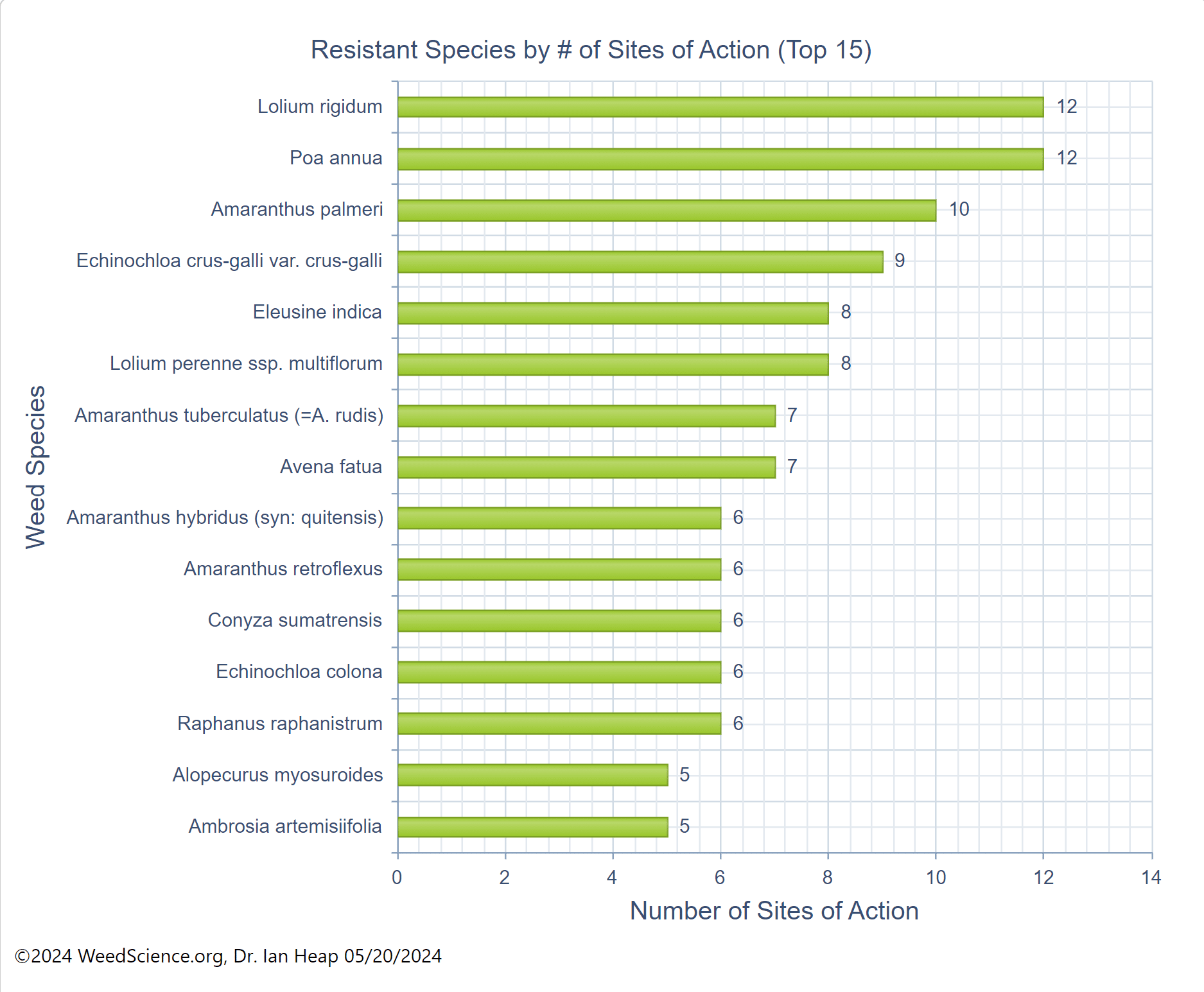

As a result, herbicide resistance developed rapidly in Australia from the 1990s onward, particularly in annual ryegrass.

Walsh, who is currently a visiting Fulbright Scholar at Kansas State University, is one of the founding fathers of the harvest weed seed control systems that have developed in Australia in response to this herbicide resistance crisis.

In a seminar, sponsored and recorded by Kansas State University, he explains how growers and researchers in Australia have come together to either adopt or develop six current systems of harvest weed seed control. All of them attempt to prevent weed seeds from exiting the back of a combine at harvest and refilling a field’s weed seedbank:

- Chaff carts: Imported from Canada, where they are known as “chaff wagons,” chaff carts follow behind a combine and collect chaff residue, where most weed seeds end up.

- Bale direct: A baler is attached to the combine, which collects the chaff and straw residue and creates bales that can be sold for livestock feed.

- Narrow windrow burning: A chute attached to the rear of the combine funnels the chaff and straw residue into a narrow row, where it can be destroyed in a controlled burn.

- Chaff lining: Chaff is funneled into a narrow row and left in place after harvest. This practice concentrates weed seeds into the row where they compete less with crops, and their exposure to the elements leads to reduced weed emergence.

- Chaff tramlining: Here, chaff is funneled into narrow rows that align with the wheel tracks of a farmer’s equipment. In a “controlled traffic farming system,” a grower attempts to use only these dedicated wheel tracks – or tramlines – as he moves equipment through the field, which reduces overall compaction across the field and produces an unfavorable environment for weed seeds in the tramlines.

- Seed impact mills: Mills attached to the back of the combine crush the chaff residue, including weed seeds, before spreading it back across the field. This system returns all residue to the field, which makes it well suited for no-till farming.

Research in western Australia suggests that using any one of these systems can, on average, produce a 60% reduction in ryegrass emergence the following year, Walsh says. This success has translated into wide scale farmer adoption: By 2014, nearly half of all Australian growers were using some form of harvest weed seed control and by 2019, adoption had risen to 75%.

Unfortunately, even as harvest weed seed control has helped many Australian growers lower their annual weed densities, current spray technology still requires blanket applications of entire fields to target those weeds, Walsh notes.

The next target for these Australian researchers and growers? Precision spray technology that can help farmers target their smaller weed populations more efficiently. “That’s the only way growers are really going to realize the benefits of low weed density,” Walsh says.

Spot-spraying, sensor-assisted equipment that can detect and destroy weeds on brown, fallow ground has been in use in Australia for two decades. Now researchers there are sorting through the recent proliferation of new camera and imaging technologies to figure out what exactly is needed for in-crop, spot-spray applications in Australian cropping systems, Walsh says.

Watch the full seminar here:

For information on harvest weed seed control research and farmer adoption here in the U.S., see these GROW news stories and research updates.

Seminar recording by Kansas State University and Dr. Michael Walsh; Article by Emily Unglesbee, GROW; Video editing by Claudio Rubione, GROW